Method for forming three-dimensional curve surface by using discrete displacement loading mode

A three-dimensional curved surface, discrete technology, applied in the stretch forming of large three-dimensional curved surface parts, sheet metal forming, can solve the problems of many process wastes, poor molding, and small uneven deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

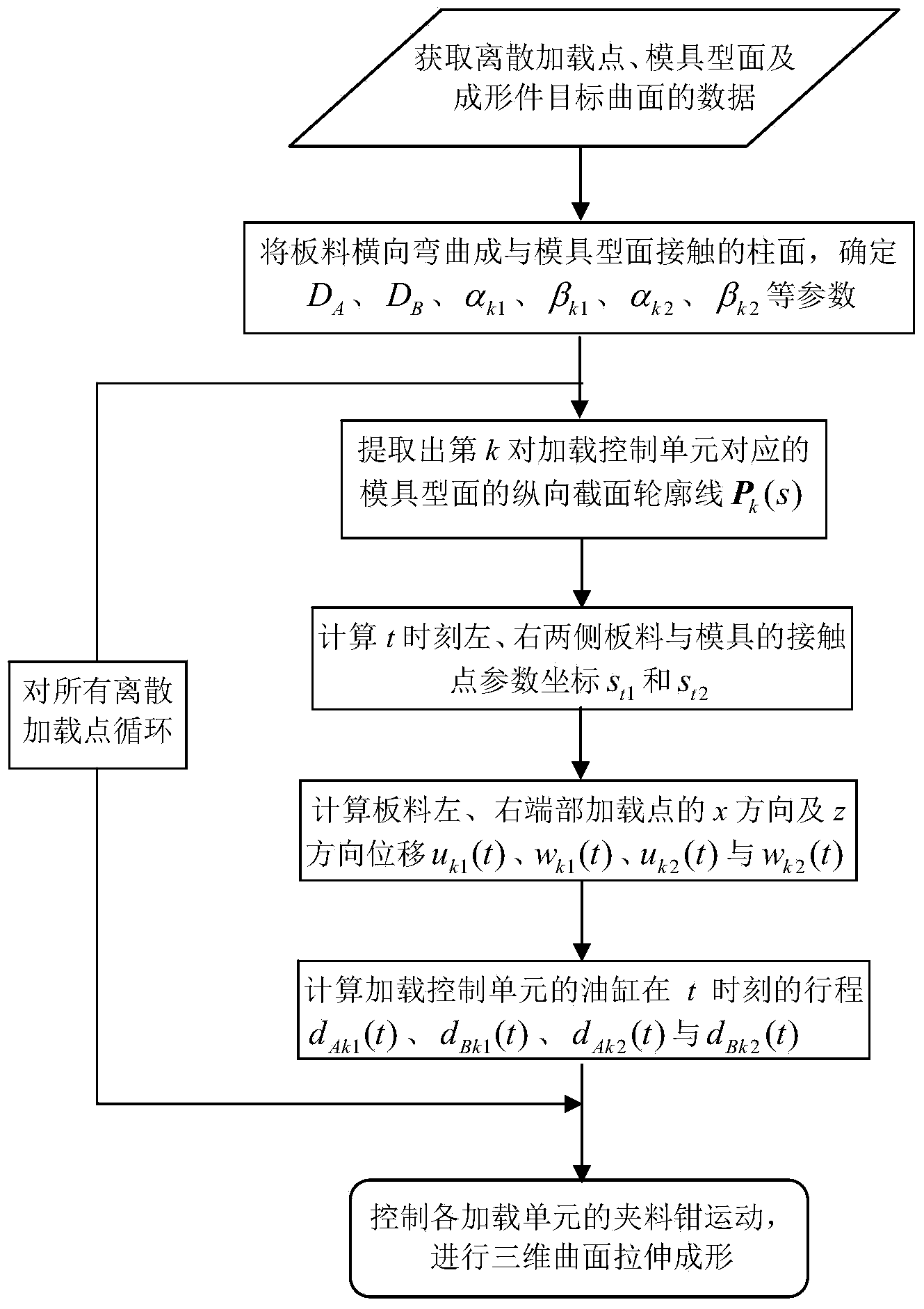

[0038] Further illustrate detailed content of the present invention and specific implementation thereof below in conjunction with accompanying drawing:

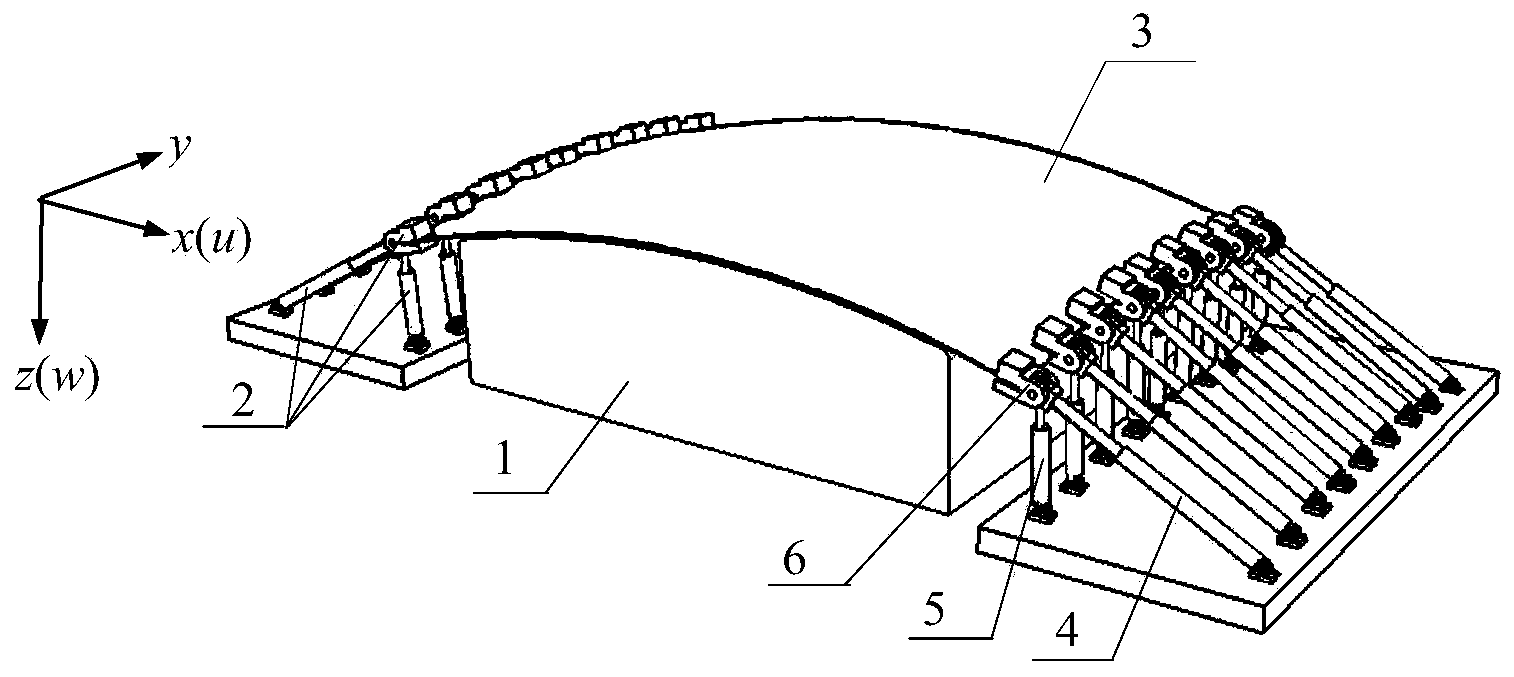

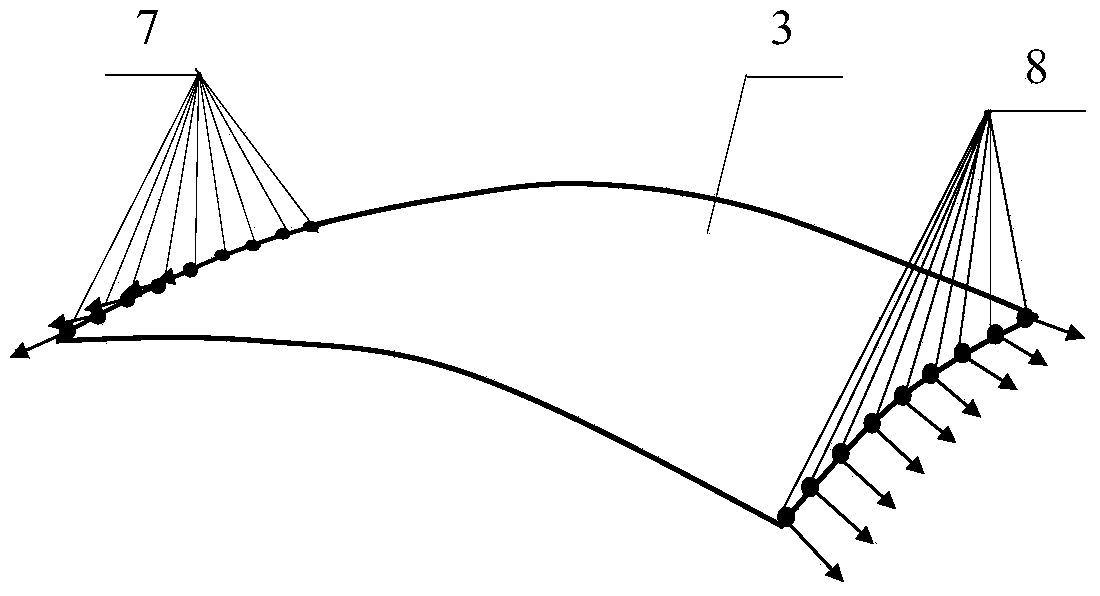

[0039] 1. Refer to figure 1 and figure 2 , the displacement load of the discrete displacement loading method is applied to a series of discrete points 7 and 8 located at both ends of the sheet through two rows of loading control units. The loading control units 2 are symmetrically arranged on the left and right sides of the drawing die 1, and the distributed and time-varying displacement loads are formed through the point-by-point independent control of each loading control unit 2 on both ends of the sheet metal.

[0040] 2. The loading control unit 2 is composed of the oil cylinder 4, the oil cylinder 5 and the material clamp 6, and one loading control unit controls one loading point at the end of the sheet metal. The movement of each loading point in the xz plane is realized by the clamp 6 of the loading control unit 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com