Betaine synthesis device and method

A technology of betaine and solution, which is applied in the fields of plant growth regulator, medicine, cosmetics, feed, and food. It can solve the problems of the impact on the purity of the final product, the difficulty of comprehensive utilization, and the by-product glycolic acid, so as to improve product profits and competition. The effect of improving the utilization rate of power and process raw materials and high purity of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

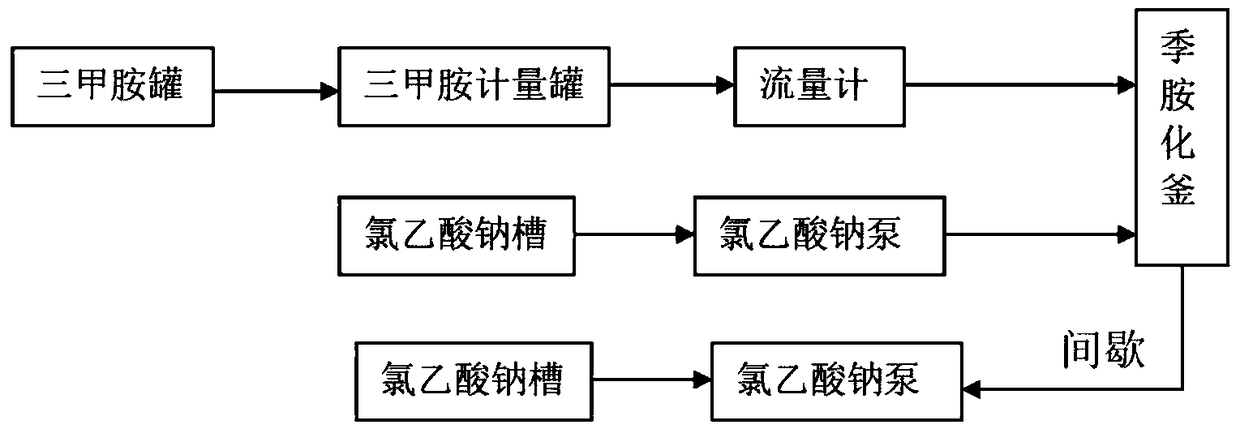

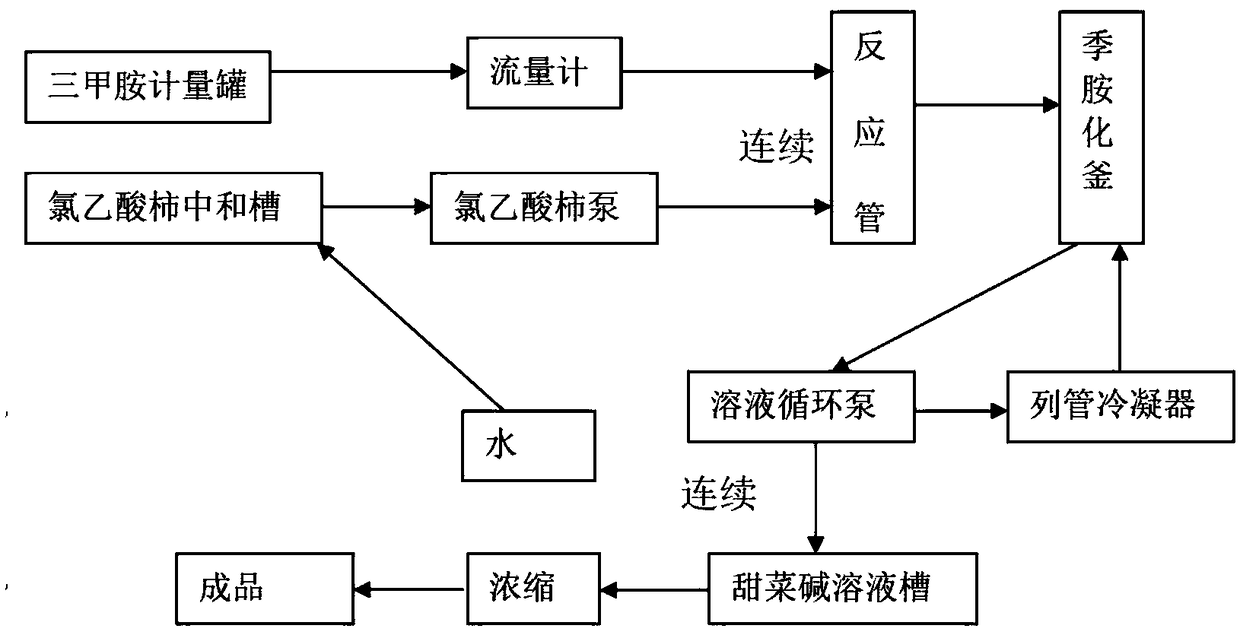

Method used

Image

Examples

Embodiment 1

[0032] First put solid chloroacetic acid into the chloroacetic persimmon neutralization tank, add raw material water, and then slowly add persimmon carbonate. The amount of water is 1.6 times the mass of chloroacetic acid, and the molar ratio of chloroacetic acid and persimmon carbonate is controlled to react in the water phase to produce chloroacetic persimmon at a molar ratio of 1.01:0.167. The pH of the reaction end point is controlled at 7.0, the temperature is controlled at 25°C, and the reaction time is controlled at 3 hours. . After the reaction is over, use the chloroacetic persimmon pump to transport the controlled flow of chloroacetic persimmon to the reaction tube of the quaternization reaction system. The reaction temperature is controlled at 40°C, the pH is controlled at 8.6, and the synthesis time is controlled at 2.5 hours. The reacted materials are pumped into the betaine solution tank, and the pH is 8.6 by controlling the flow rate of the incoming and outgoing...

Embodiment 2

[0034] The specific steps of this example are consistent with Example 1, the difference is that this example uses chloroacetic acid with a molar ratio of 1.015:0.167 to react with persimmon carbonate in the water phase to generate chloroacetic persimmon, the pH is controlled at 7.1, and the temperature is controlled at 30 ℃; persimmon chloroacetate with a molar ratio of 1.0:0.335 and trimethylamine were synthesized by quaternization, the synthesis reaction temperature was controlled at 51 °C, the pH was controlled at 9.5, and the synthesis time was 3 hours.

Embodiment 3

[0036] The specific steps of this embodiment are consistent with those of Example 1, except that the present embodiment 3 uses chloroacetic acid with a molar ratio of 1.02:0.167 to react with persimmon carbonate in the water phase to generate chloroacetic persimmon, the pH is controlled at 7.2, and the temperature is controlled at 35°C; persimmon chloroacetate with a molar ratio of 1.0:0.34 and trimethylamine were synthesized by quaternization, the synthesis reaction temperature was controlled at 51°C, the pH was controlled at 9.0, and the synthesis time was 2.8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com