Production method of 5754-H32 aluminum alloy plate strip

A technology of aluminum alloy strip and production method, which is applied in the field of aluminum alloy manufacturing, can solve problems such as inability to anneal in parallel furnaces, complex production process, and different temperature ranges, and achieve lower requirements for temperature measurement accuracy and furnace temperature uniformity, and reduce production cost, reduction of process waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

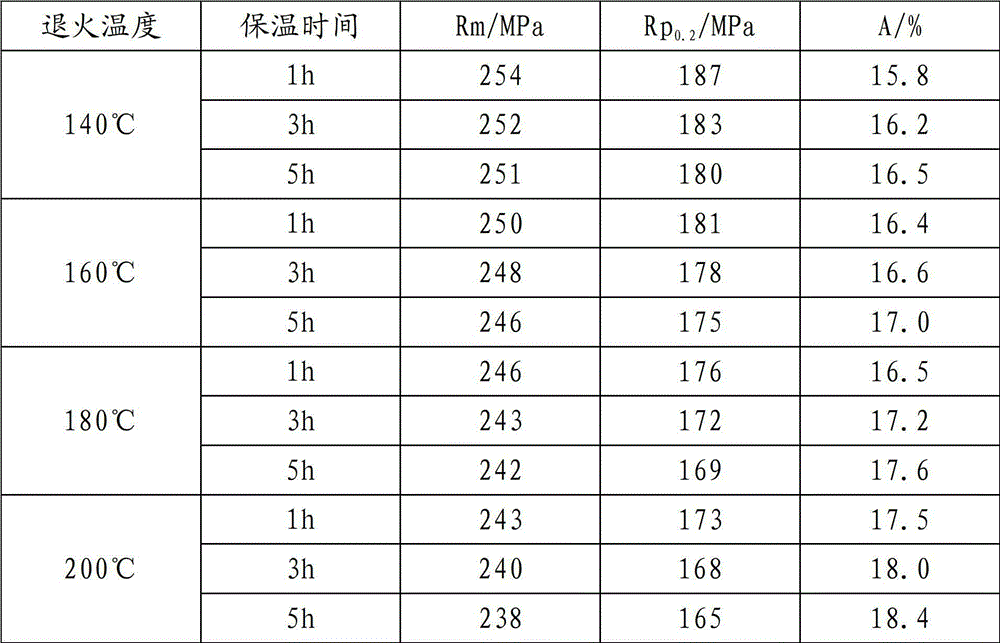

Embodiment 1

[0027] The short-process production method of 5754-H32 aluminum alloy plate and strip in this embodiment includes the following production process: melting and casting→sawing→face milling→heating→hot rolling→cold rolling→stabilizing annealing→finishing→packaging.

[0028] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (wt%):

[0029] Al

Si

Fe

Cu

mn

96.2611

0.0976

0.2516

0.0028

0.2405

Mg

Ti

Cr

Zn

Ni

2.9369

0.0211

0.1669

0.0181

0.0034

[0030] The melting temperature is 730-745°C, the refining temperature is 725-735°C, and the casting temperature is 685-700°C.

[0031] (2) Heating: heat the ingot to 490°C and keep it warm for 4 hours.

[0032] (3) Hot rolling: hot rolling production is adopted, the temperature of the hot rough rolling finish rolling pass is 440°C, the hot finish rolling finish rolling temperatur...

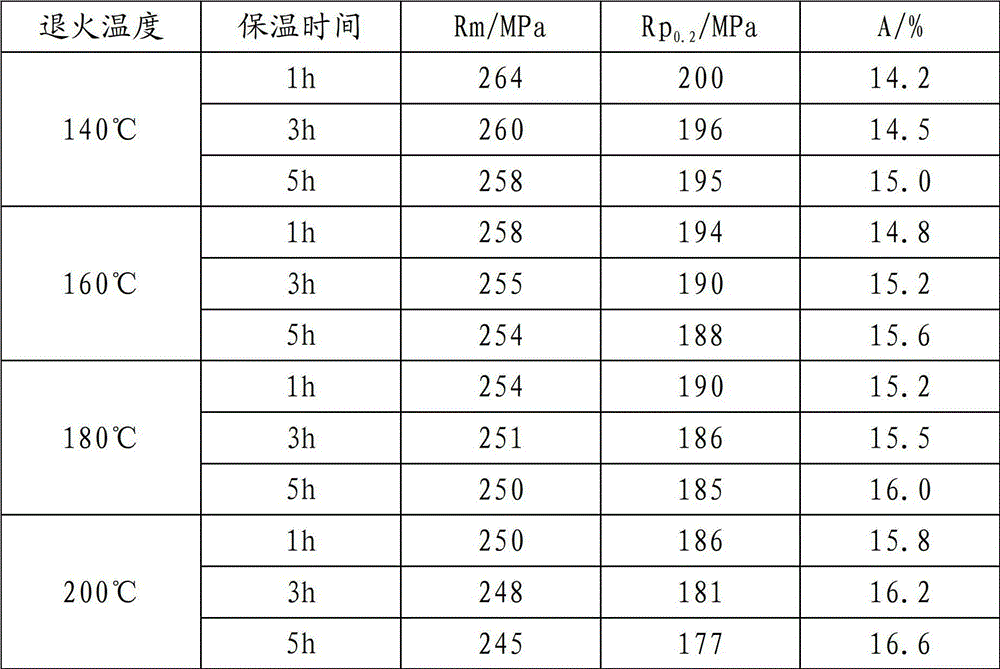

Embodiment 2

[0039] The production method of the 5754-H32 aluminum alloy plate and strip in this embodiment includes the following production process: melting and casting→sawing→face milling→heating→hot rolling→cold rolling→stabilizing annealing→finishing.

[0040] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is:

[0041] Al

Si

Fe

Cu

mn

96.0423

0.0531

0.1753

0.0025

0.3025

Mg

Ti

Cr

Zn

Ni

3.2031

0.0179

0.1834

0.0176

0.0023

[0042] The melting temperature is 730-750°C, the refining temperature is 720-730°C, and the casting temperature is 690-700°C.

[0043] (2) Heating: heat the ingot to 505°C and keep it warm for 3 hours.

[0044] (3) Hot rolling: Hot continuous rolling is adopted, the temperature of the hot rough rolling finish rolling pass is 435°C, the hot finish rolling finish rolling temperature is 323°C, and the thickn...

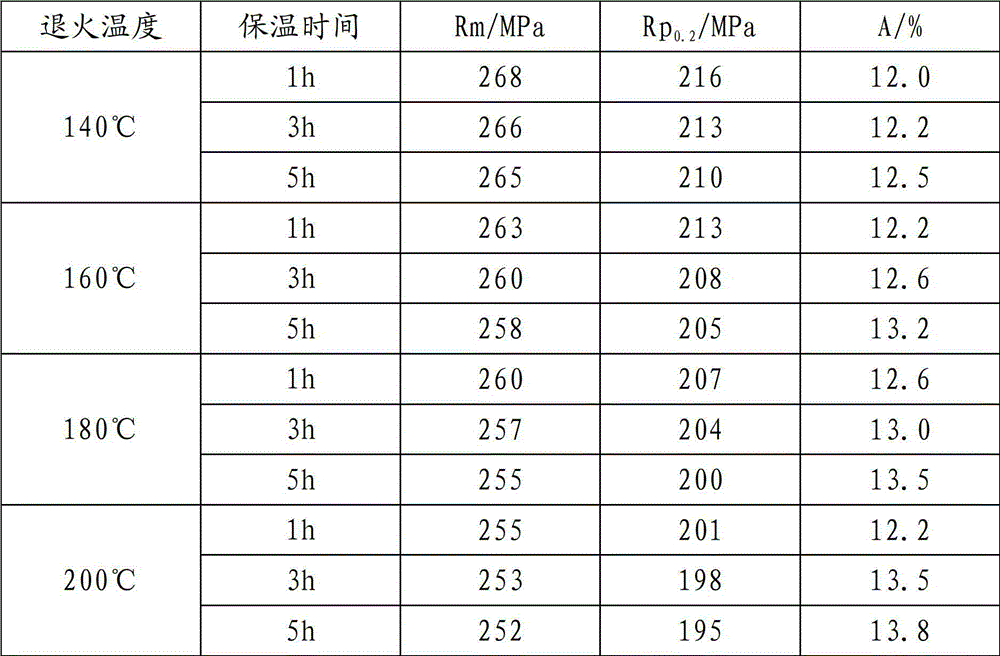

Embodiment 3

[0051] The production method of the 5754-H32 aluminum alloy plate and strip in this embodiment includes the following production process: melting and casting→sawing→face milling→heating→hot rolling→cold rolling→stabilizing annealing→finishing.

[0052] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (wt%):

[0053] Al

Si

Fe

Cu

mn

96.0492

0.0591

0.2762

0.0035

0.2792

Mg

Ti

Cr

Zn

Ni

3.1496

0.0212

0.1463

0.0128

0.0029

[0054] The melting temperature is 730-745°C, the refining temperature is 725-740°C, and the casting temperature is 690-700°C.

[0055] (2) Heating: the ingot is heated to 515°C and then kept for 3 hours.

[0056] (3) Hot rolling: Hot continuous rolling is adopted, the temperature of the hot rough rolling finish rolling pass is 443°C, the hot finish rolling finish rolling temperature is 345°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com