Method for preventing deformation of guyed assembling and welding large-scale horizontal storage tank shell section

A cable-type, anti-deformation technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient disassembly and assembly, unable to adjust the pre-tightening force, etc., and achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

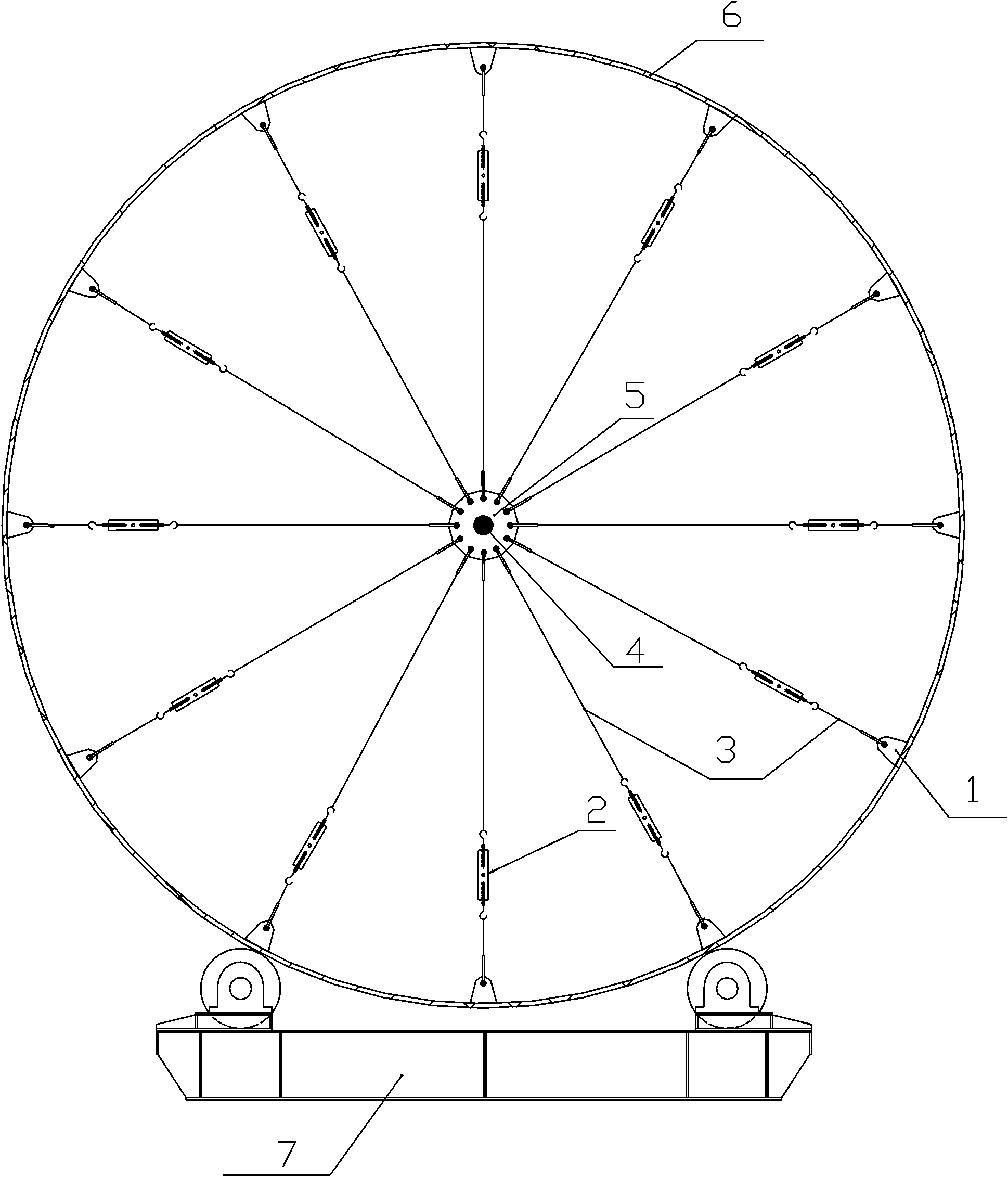

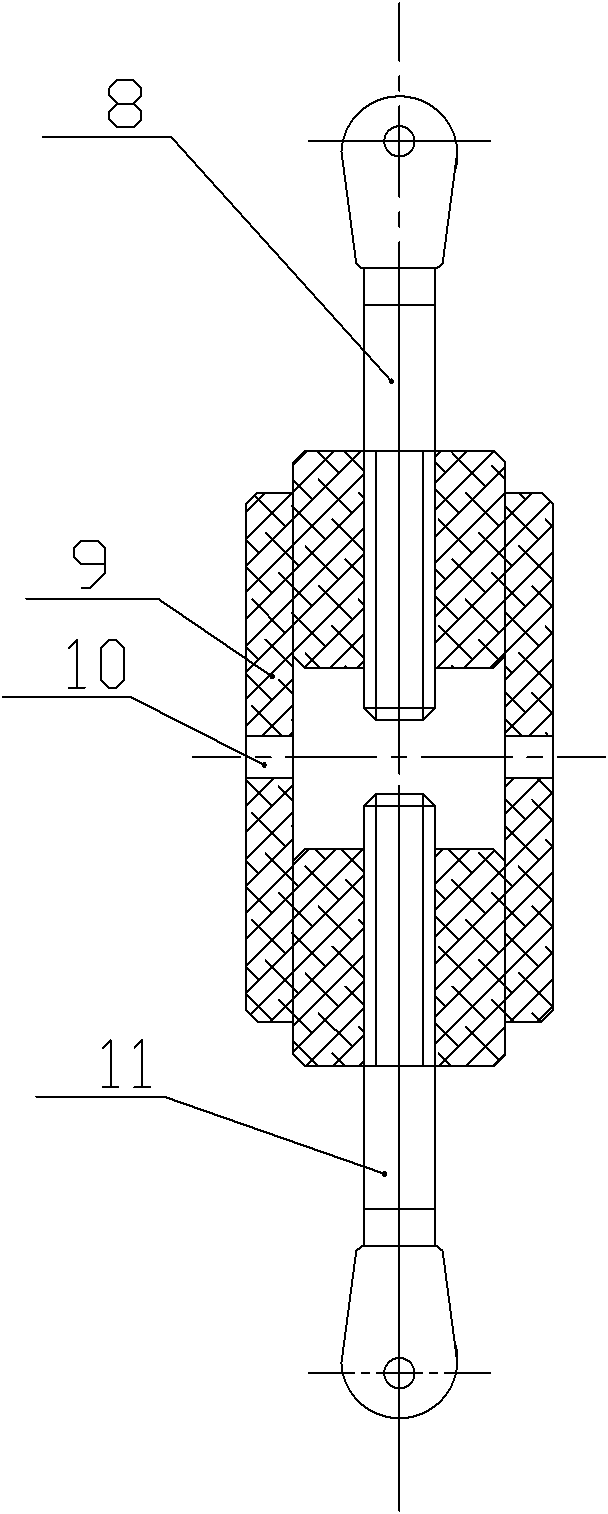

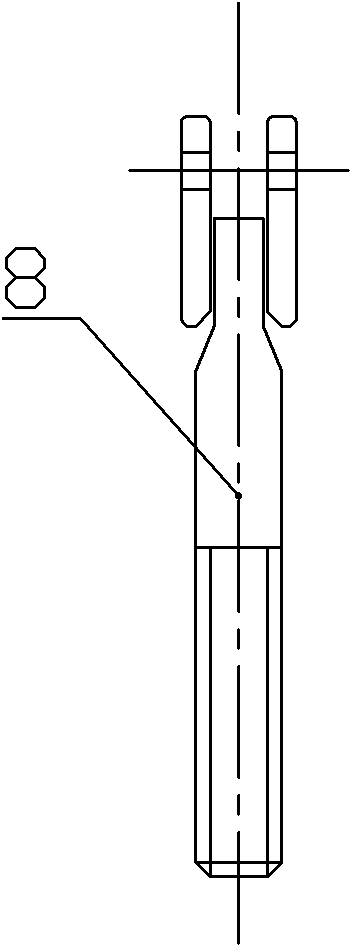

[0020] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, see Figure 1 to Figure 4 :

[0021] The anti-deformation cable for assembling and welding large-scale horizontal storage tanks implemented according to the present invention is used for assembling and welding the cylinder joint 6 of the large-scale horizontal storage tank body. The structure of this embodiment is similar to the spokes of bicycle wheels. The arc-shaped shell plate is connected to the cable, and the cable generates a pre-tightening force to resist welding deformation. In order to conveniently adjust the tension of the cable according to the site conditions, the cable is composed of lug plate 1, tightening device 2, steel wire rope 3, connecting plate 6, and bearing 4. The lug plate 1 is evenly distributed and connected to the arc-shaped shell plate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com