A Multifunctional Automatic Welding Fixture

An automatic welding and multi-functional technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large volume and weight, increased manufacturing cost, and a large number of tooling, and achieves strong versatility and reduced Production cost and the effect of improving the degree of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

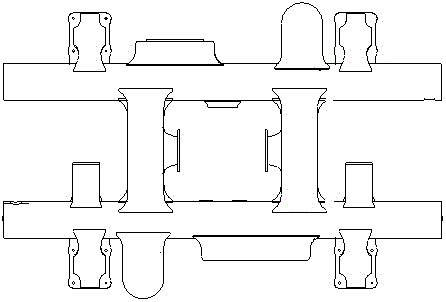

[0024] Attached below Figures 5 to 7 The present invention is described in further detail.

[0025] Such as Figure 5 As shown, the multifunctional automatic welding fixture of the present invention includes: a fixture main body 1, a transition plate 2, a side beam adjustment mechanism 3, a cross beam adjustment mechanism 4, a lateral beam pressing mechanism 5, and a side beam end positioning mechanism 8.

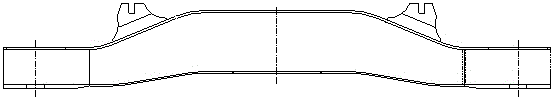

[0026] Such as Figure 6 As shown, the fixture main body 1 is a welded structure of two rectangular steel pipes and steel plates, which has high rigidity and meets the requirement of rigid fixation.

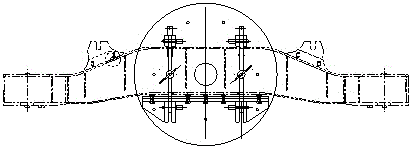

[0027] The transition plate 2, the center of which is connected to the middle part of the bottom surface of the clamp body 1 through a pin shaft, serves as a connection between the clamp body of the present invention and the welding robot, and the pin shaft is used for positioning so that the center line of the clamp body coincides with the robot turntable clamp, thereby G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com