Method and device for detecting end surface of optical fiber connector

A fiber optic connector and detection method technology, applied in the direction of measuring devices, optical devices, optical instrument testing, etc., can solve the problems of surface damage and pollution of the tested part, difficulty in measuring the end face of the optical fiber, damage to structural components, etc., and achieve automation High, strong anti-interference ability and accuracy, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

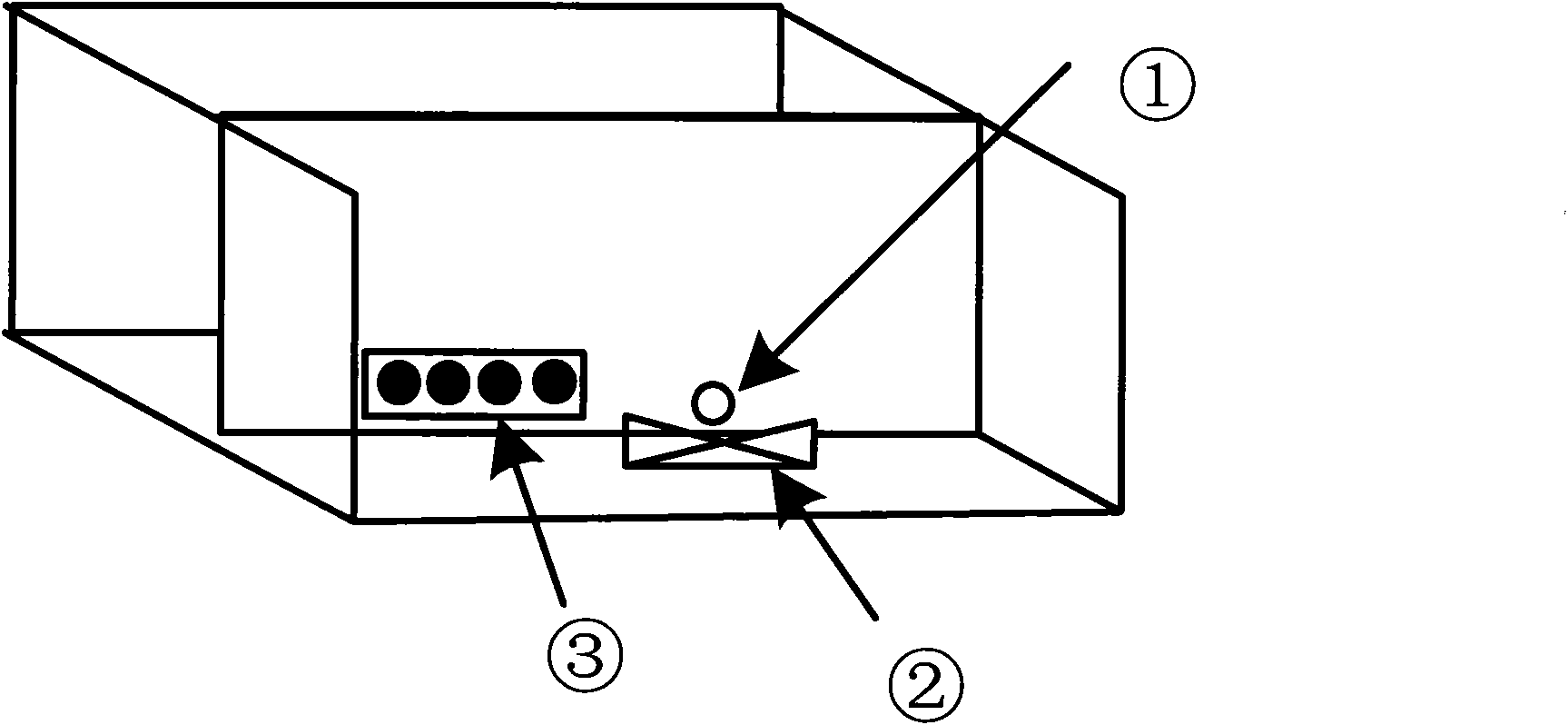

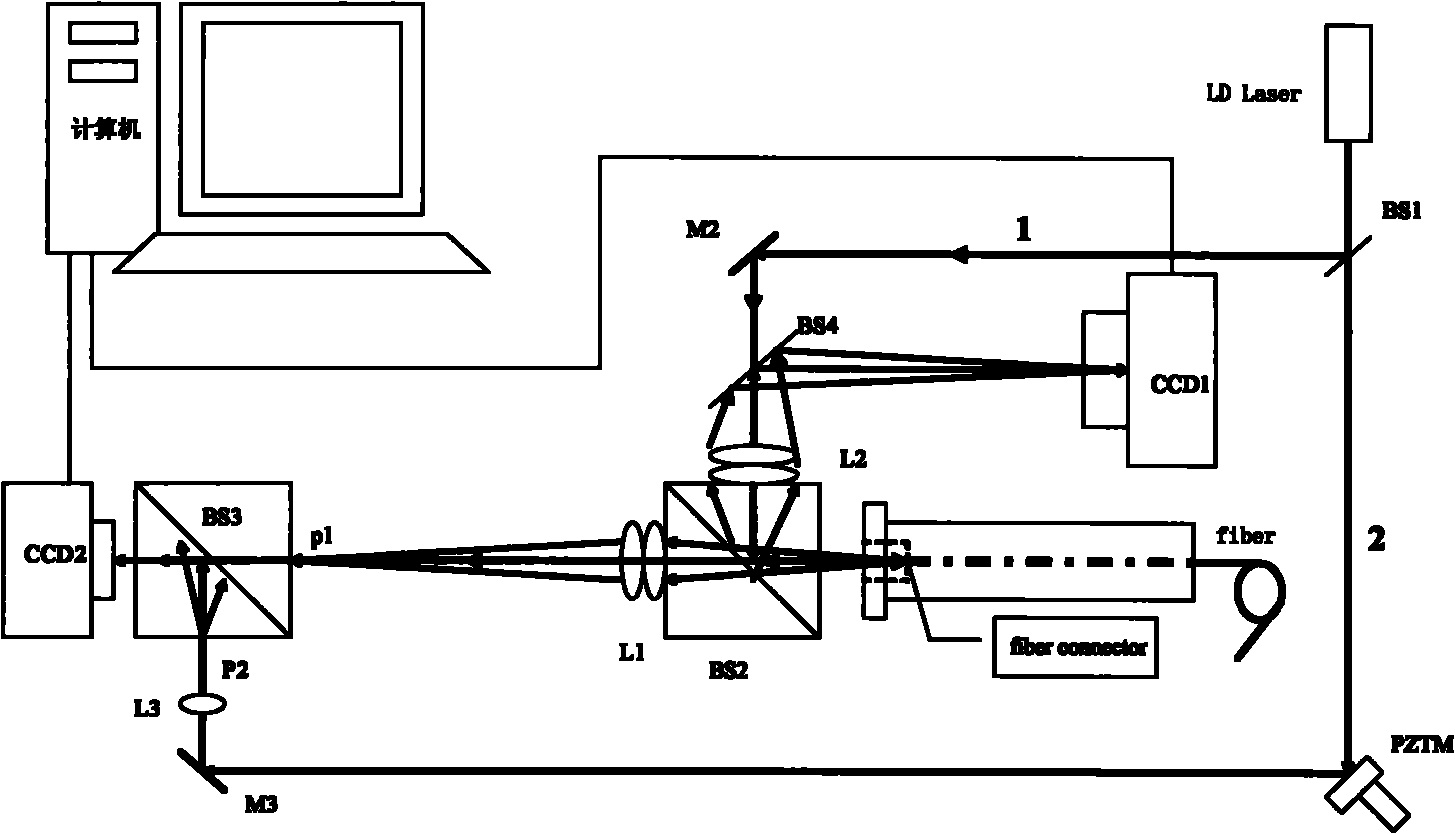

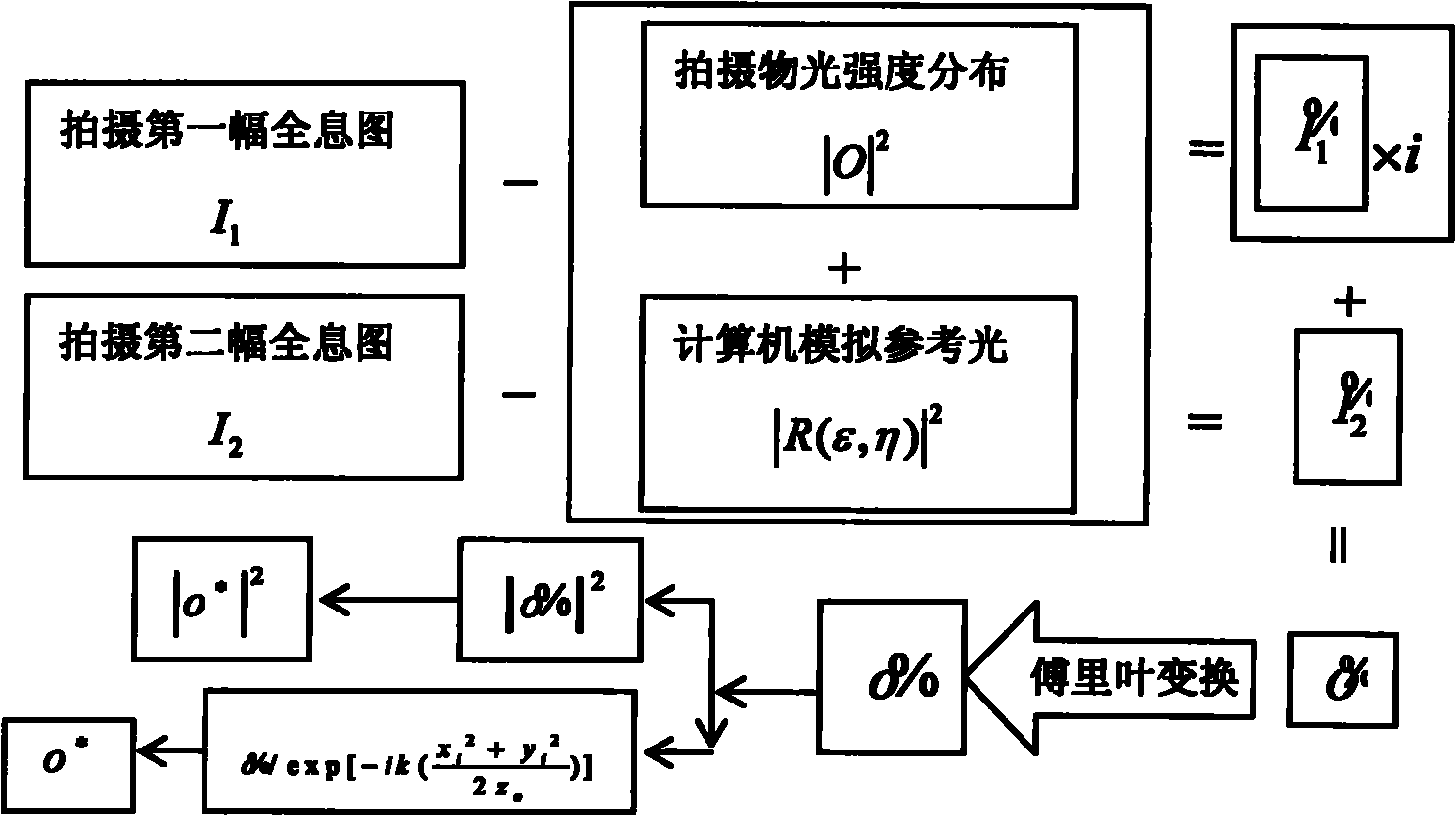

[0018] figure 1 It is a schematic diagram of the appearance of the present invention. The light entrance ① of the optical fiber connector is the optical interface between the end face of the optical fiber connector under test and the device of the present invention; the fixing frame ② of the optical fiber connector is used to fix the optical fiber connector under test; transfer interface. figure 2 The light signal of the middle laser light source LD is split, wherein the light path 1 is the reference light path, and the light path 2 is the object light path. The reference light enters the CCD1 after being focused and reflected, and then sent to the computer through the USB interface ③. The object light is reflected and focused, and enters the end face of the optical fiber connector under test of the optical fiber connector fixing frame ② through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com