Machine for the tobacco processing industry and method for obtaining the position of a strip of pre-printed material in the machine

A material belt, a technology in the processing industry, applied in the machine field of the tobacco processing industry, can solve the problem of inability to achieve flexibility in marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

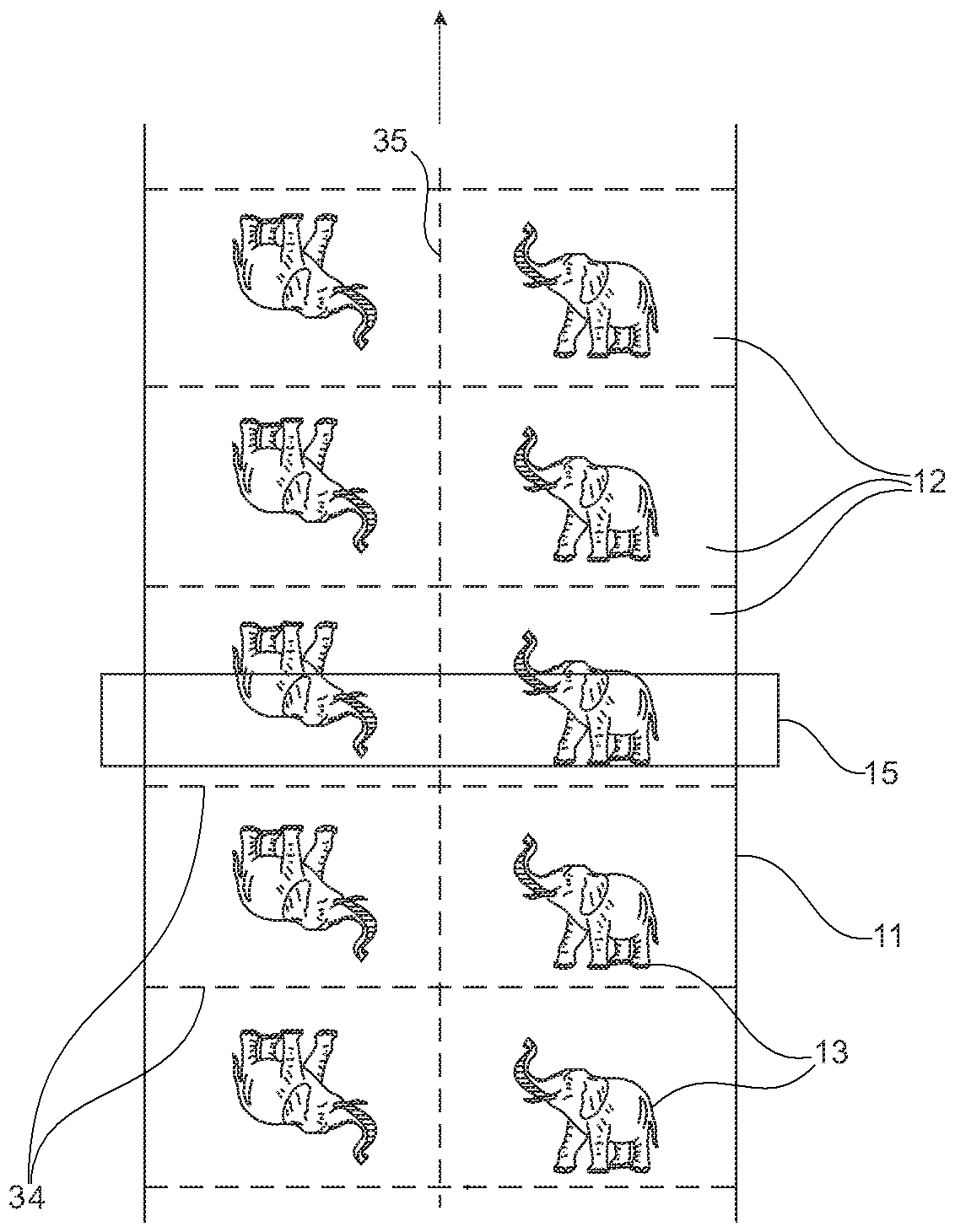

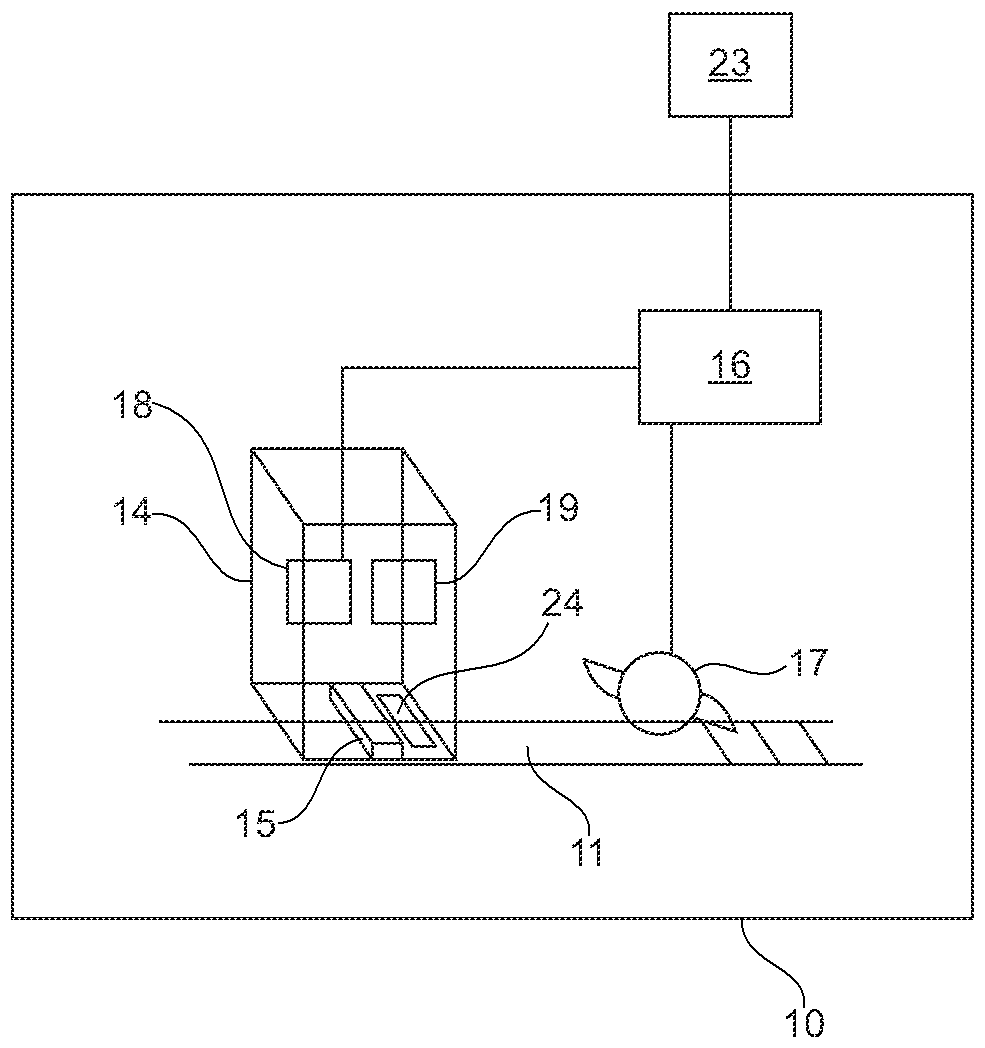

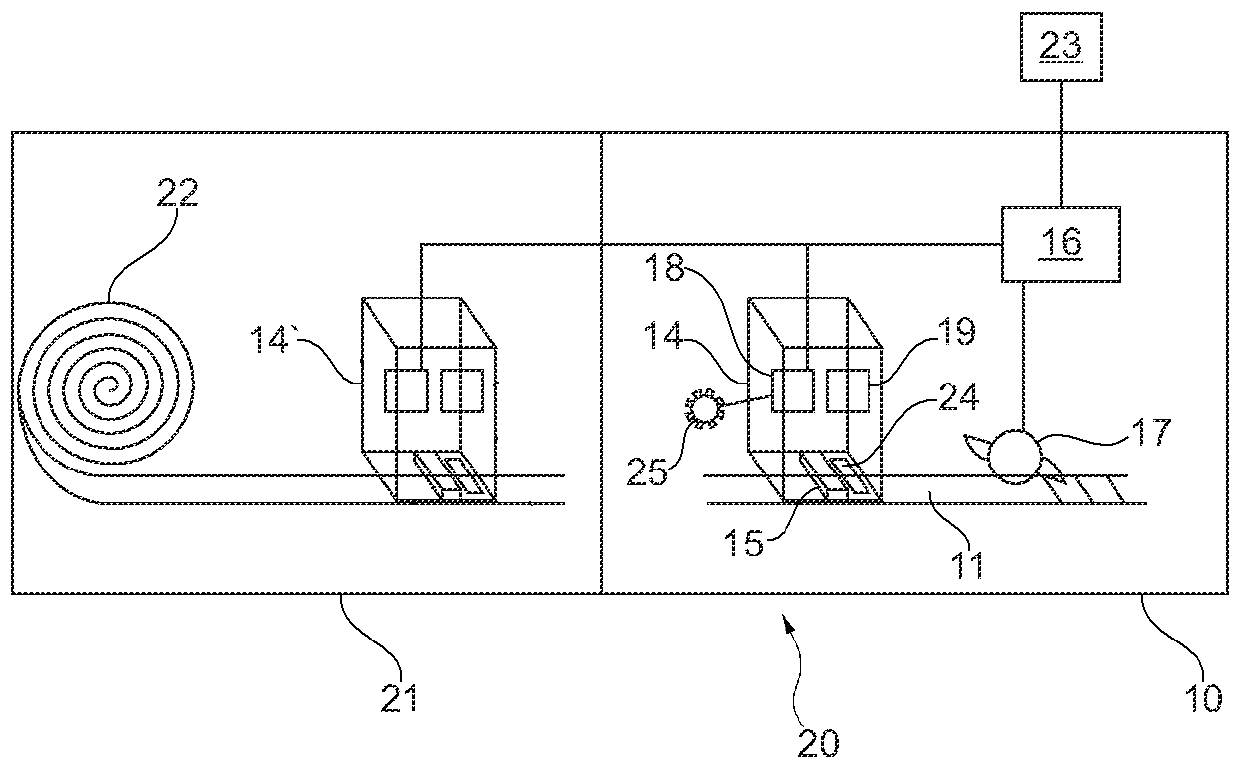

[0021] figure 1 A machine 10 for the tobacco processing industry is shown in which a web 11 of printable or printed material, such as a paper web, is endlessly processed. The machine 10 includes a sensor device 14 with an optical camera 15 which is arranged in the machine 10 to capture images of the printed side of the material web 11 . The camera 15 is preferably a line scan camera, but may also be an area scan camera. Such as figure 2 As shown, the line scan camera 15 preferably extends over the entire width of the material web 11 . It is also possible for the camera 15 to extend over only a part of the width of the material web 11 . The printed side of the strip of material 11 is at figure 1 In the example of , it points upwards, that is to say towards the sensor device 14 . In addition, the machine 10 also includes a machine control mechanism 16 and a cutting mechanism 17 for cutting the strip of material 11 along a periodically repeating cutting line 34, see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com