Efficient machining method of precise valve hole

A processing method and valve hole technology, which is applied in the field of mechanical processing, can solve the problems of insufficient precision, low product qualification rate, and high processing cost, and achieve the effects of improving physical properties, processing efficiency, and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

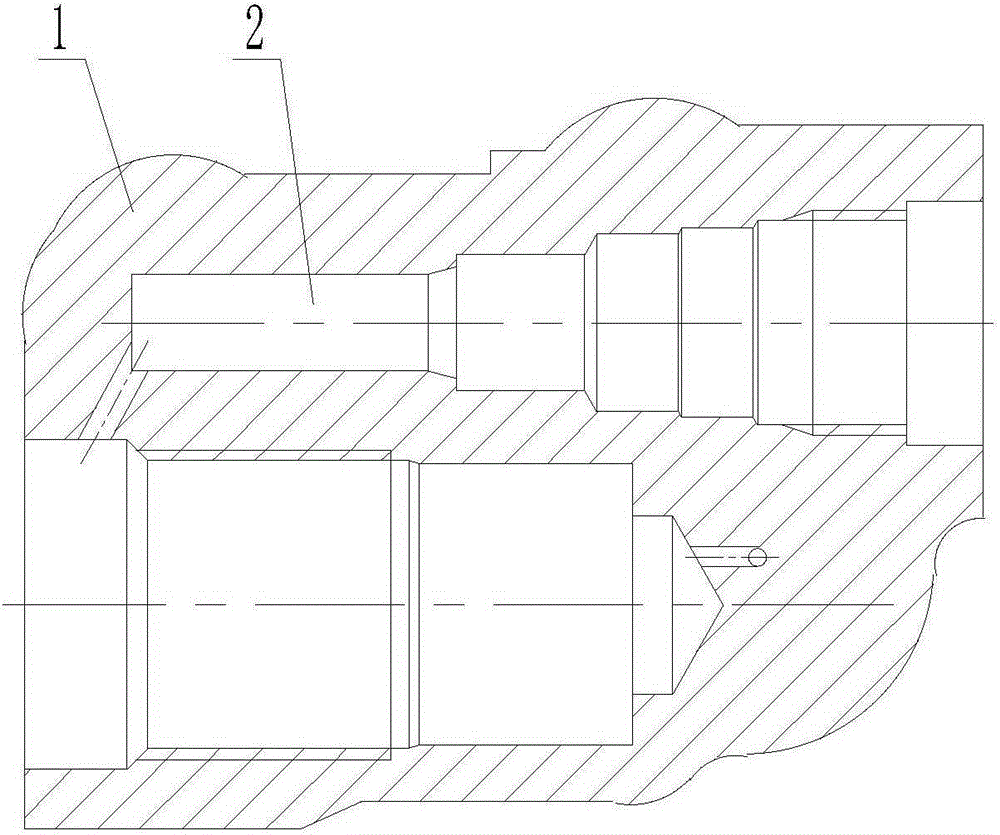

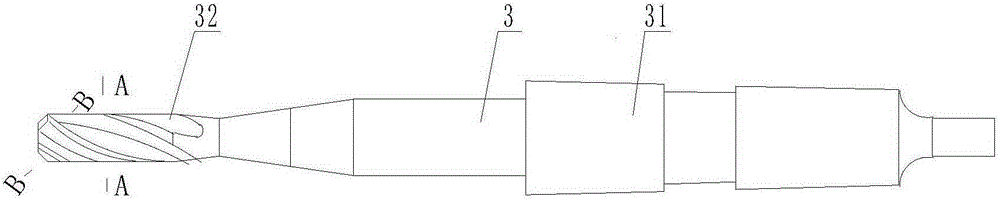

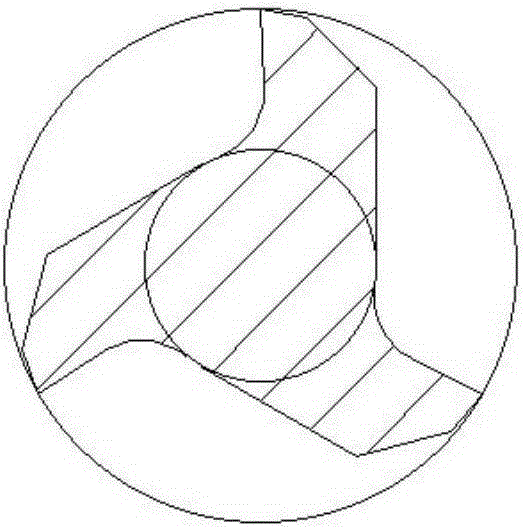

Embodiment 1

[0051] Drilling: Use a φ9.5mm drill bit to drill a precision valve hole 2 on the valve body 1. The hole depth of the precision valve hole 2 is 90.57mm; Reaming: Use a φ9.7mm flat-bottomed drill to ream the hole, and the precision valve hole after reaming The hole depth of 2 is 90.57mm; rough reaming: use rough reamer 3 to process the hole to φ9.98mm, use kerosene cooling during the processing, cutting amount V=6m / min, f=0.7mm / n, speed 300r / min ; Fine reaming: use fine reamer 4 to process the hole to φ10mm, the processing process adopts kerosene cooling, the cutting amount V=4m / min, f=0.5mm / n, and the speed is 200r / min; edgeless reaming squeezes the hole: Several groups of edgeless reaming knives are used to process the precision valve hole 2 sequentially, and the bladeless reaming knives 5 are installed in the floating chuck for processing. The cutting amount V=2m / min, f=0mm / n, and the speed is 100r / min, kerosene cooling, the outer diameter of the edgeless reamer 5 increases ...

Embodiment 2

[0053] Drilling: Use a φ9.5mm drill bit to drill a precision valve hole 2 on the valve body 1. The hole depth of the precision valve hole 2 is 90.43mm; Reaming: Use a φ9.7mm flat-bottomed drill to ream the hole, and the precision valve hole after reaming The hole depth of 2 is 90.43mm; rough reaming: use rough reamer 3 to process the hole to φ9.98mm, use kerosene cooling during the processing, cutting amount V=6m / min, f=0.7mm / n, speed 300r / min ; Fine reaming: use fine reamer 4 to process the hole to φ10mm, the processing process adopts kerosene cooling, the cutting amount V=4m / min, f=0.5mm / n, and the speed is 200r / min; edgeless reaming squeezes the hole: Several groups of edgeless reaming knives are used to process the precision valve hole 2 sequentially, and the bladeless reaming knives 5 are installed in the floating chuck for processing. The cutting amount V=2m / min, f=0mm / n, and the speed is 100r / min, kerosene cooling, the outer diameter of the edgeless reamer 5 increases ...

Embodiment 3

[0055] Drilling: use a φ9.5mm drill bit to drill a precision valve hole 2 on the valve body 1, and the hole depth of the precision valve hole 2 is 90.5mm; reaming: use a φ9.7mm flat bottom drill to ream the hole, and the precision valve hole after reaming The hole depth of 2 is 90.5mm; rough reaming: use rough reamer 3 to process the hole to φ9.98mm, use kerosene cooling during the processing, cutting amount V=6m / min, f=0.7mm / n, speed 300r / min ; Fine reaming: use fine reamer 4 to process the hole to φ10mm, the processing process adopts kerosene cooling, the cutting amount V=4m / min, f=0.5mm / n, and the speed is 200r / min; edgeless reaming squeezes the hole: Several groups of edgeless reaming knives are used to process the precision valve hole 2 sequentially, and the bladeless reaming knives 5 are installed in the floating chuck for processing. The cutting amount V=2m / min, f=0mm / n, and the speed is 100r / min, kerosene cooling, the outer diameter of the edgeless reamer 5 increases ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com