Device for measuring pipe ovality

A technology for measuring the ellipticity of pipes, applied in the direction of mechanical counter/curvature measurement, etc., which can solve the problems of inaccurate determination of the extreme values of the major axis and minor axis, difficulty in achieving 360-degree rotation, and difficulty in parallelism, etc., to achieve measurement accuracy With economic applicability, easy to read and save, saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

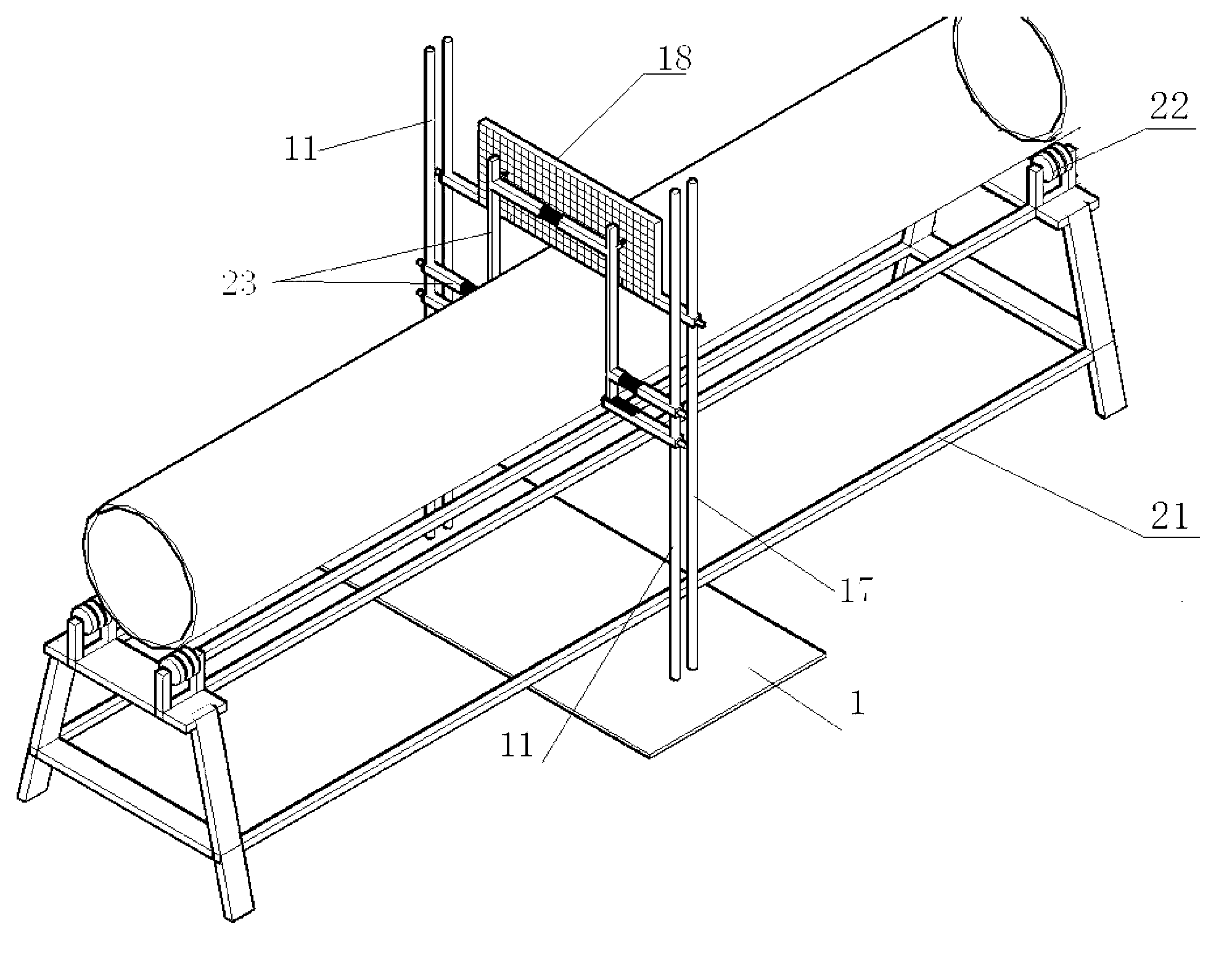

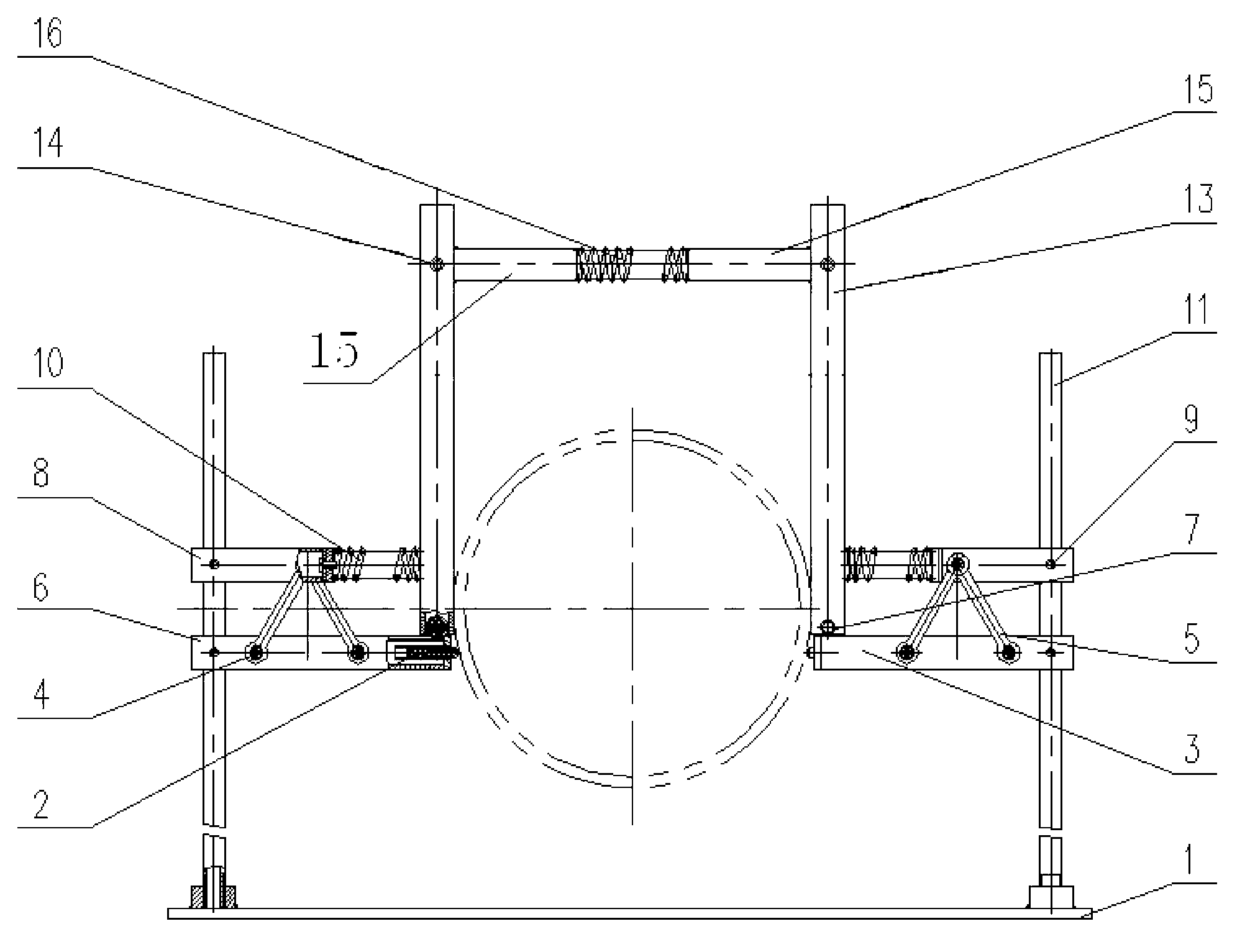

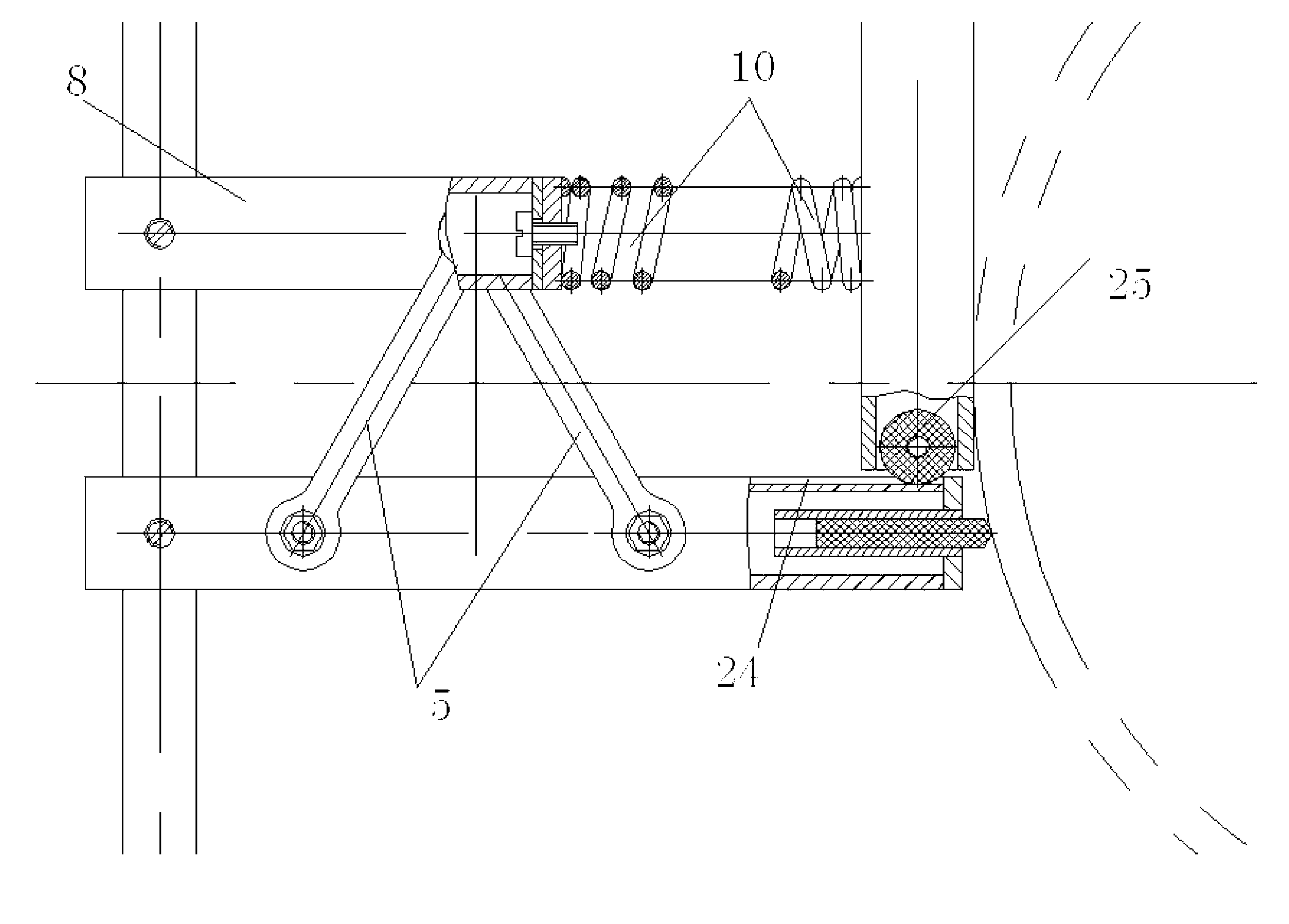

[0021] This embodiment provides a device for measuring the ellipticity of pipelines, the overall structure diagram is as follows figure 1 As shown, the pipe to be tested is placed on a pipe support 21 with rollers 22 . The measuring device mainly includes a drawing board 18 detachably mounted on two drawing board columns 17, an ellipticity measuring mechanism connected to the two measuring columns 11, and a long-axis endpoint calibration mechanism. The profile of the ellipticity measuring mechanism is a "several"-shaped portal frame 23 located on the same plane with left and right symmetry. Two drawing board uprights 17 and two measuring uprights 11 are vertically fixed on the base 1, and the drawing board 18 and " few " glyph frame 23 are parallel to each other. During the measurement, the pipeline to be tested is clamped in the "several" shaped portal frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com