Direct-reading type calipers for measuring ovality of pipeline

A technology for measuring the ellipticity of pipes, applied in the field of direct-reading calipers, which can solve the problems that affect the accuracy of the value, cannot accurately determine the maximum or minimum distance point, and the fastening screw is not firm, so as to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

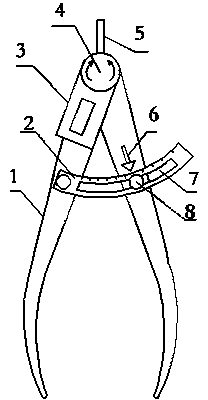

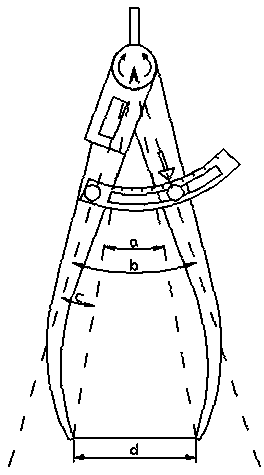

[0016] like figure 1 As shown, a direct-reading caliper for measuring pipeline ellipticity of the present invention includes a caliper body, and the caliper body includes two pincer legs 1 whose ends are hinged by a hinge shaft, and the two pincer legs 1 can rotate relatively around the hinge shaft . According to the installation requirements of the rotation angle sensor 4, the rotation angle sensor 4 is installed on the hinge shaft, and the hinge shaft passes through the center of the rotation angle sensor 4, and the rotation angle sensor 4 is used to detect the relative rotation angle signals of the two pliers legs 1. One of the pincer legs is provided with a digital display box 3, and an integrated circuit board is arranged in the digital display box 3, and a microprocessor is integrated on the integrated circuit board, and a display screen connected with the microprocessor signal is provided on the digital display box 3. The microprocessor is used to process and calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com