Method for determining dimensions of ring radially-axially rolled blank

A blank size, axial rolling technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of unguaranteed product performance, long production cycle and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

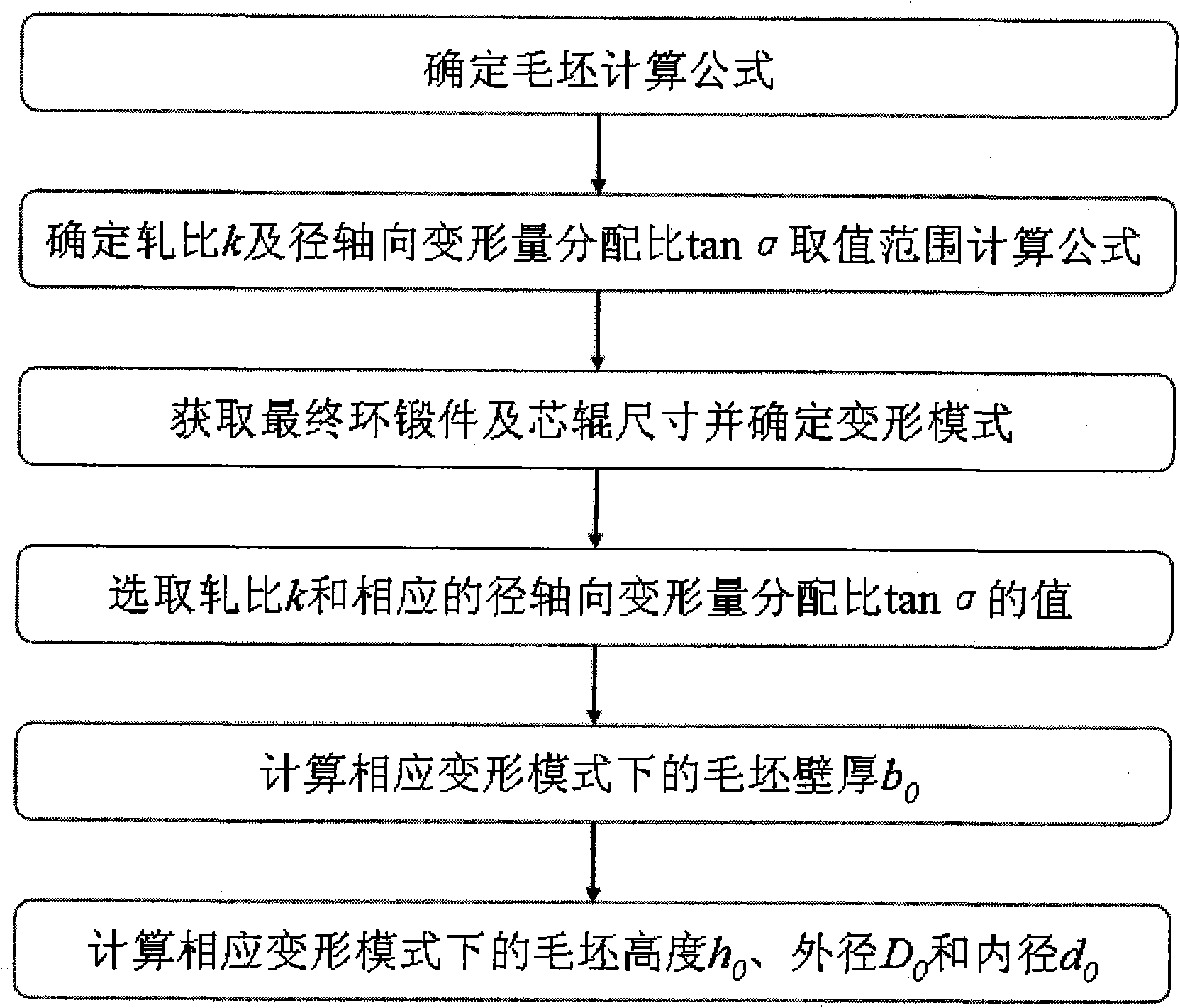

[0075] This embodiment is a method for determining the diameter and axial rolling blank size of a ring, and the specific steps are as follows:

[0076] Step 1, determine the blank size calculation formula, the blank size includes the outer diameter D of the ring blank 0 , inner diameter d 0 , height h 0 , wall thickness b 0 ;

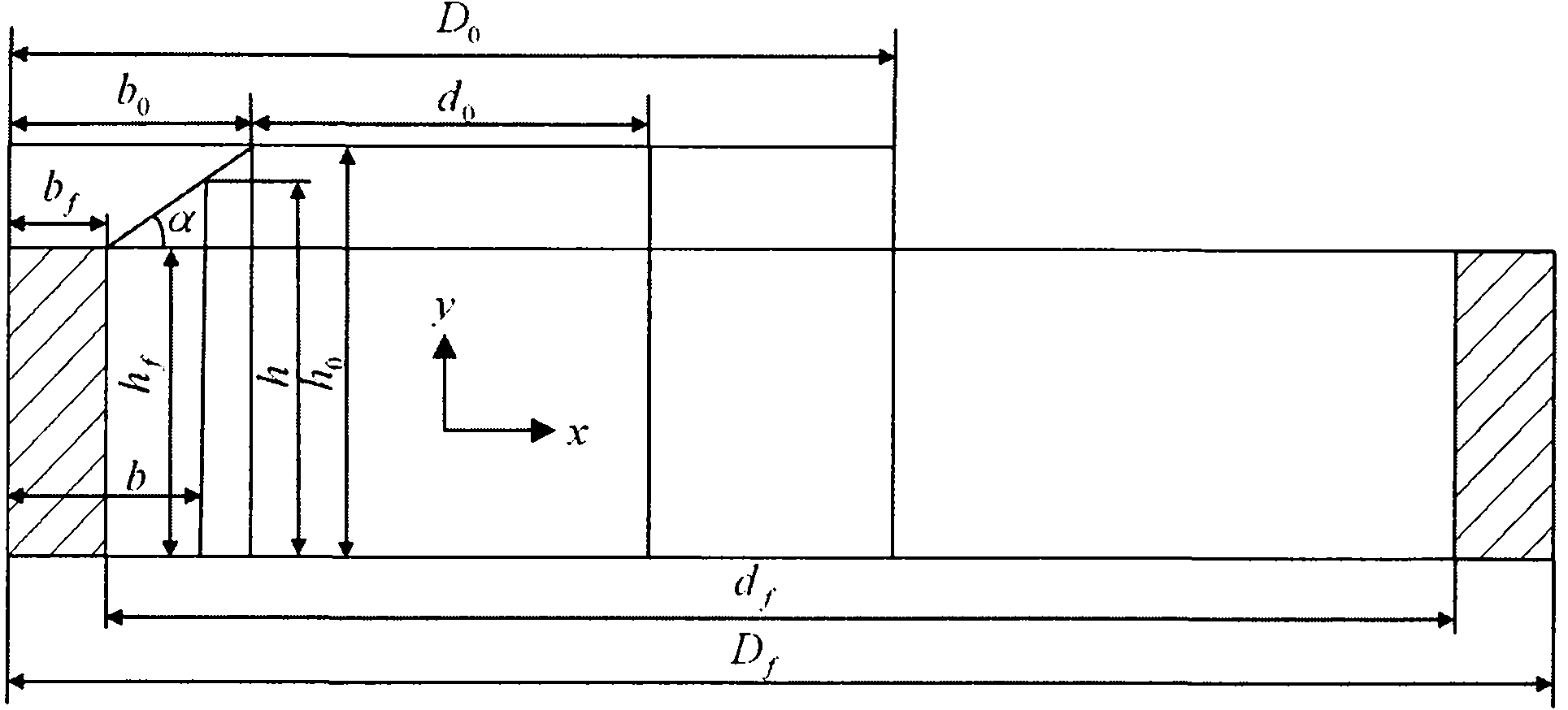

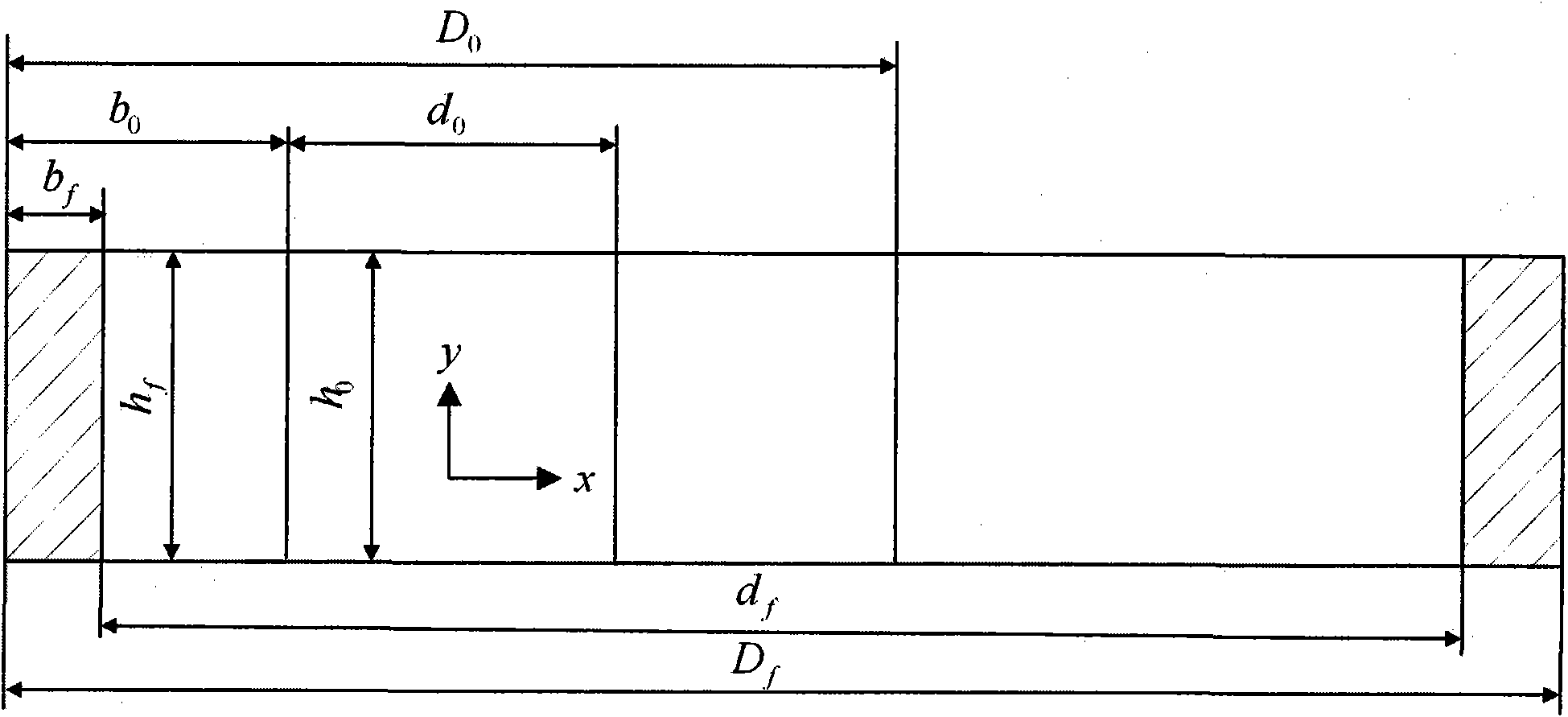

[0077] as shown in picture 2. There are three deformation modes in the radial and axial rolling forming process of the ring: (a) wall thickness reduction, height reduction, and diameter expansion, as shown in Fig. 2(a); (b) wall thickness reduction, height The diameter remains unchanged, as shown in Figure 2(b); (c) the wall thickness decreases, the height increases, and the diameter expands. In Figure 2, D 0 , d 0 , h 0 , b 0 are the outer diameter, inner diameter, height and wall thickness of the ring blank; D f , d f , h f , b f are the outer diameter, inner diameter, height and wall thickness of the final ring, respectively; α is the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com