Method for measuring deformation of metallic material in hyperthermia mechanical test as well as observation instrument

A technology of high-temperature mechanics and metal materials, applied in scientific instruments, instruments, measuring devices, etc., can solve the problems of easy damage of measuring instruments and inaccurate deformation measurement methods, and achieve the effect of improving the accuracy of deformation measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

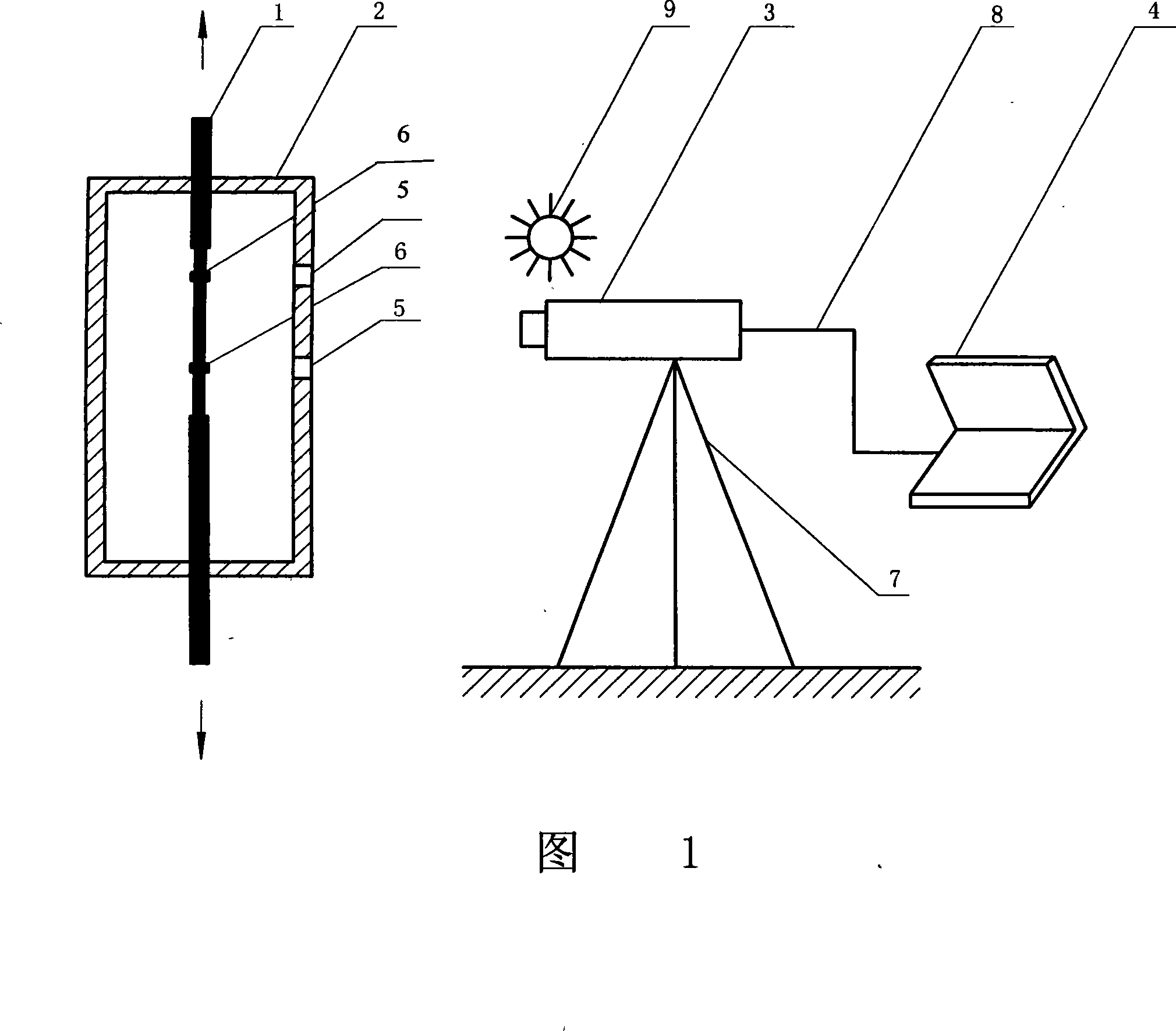

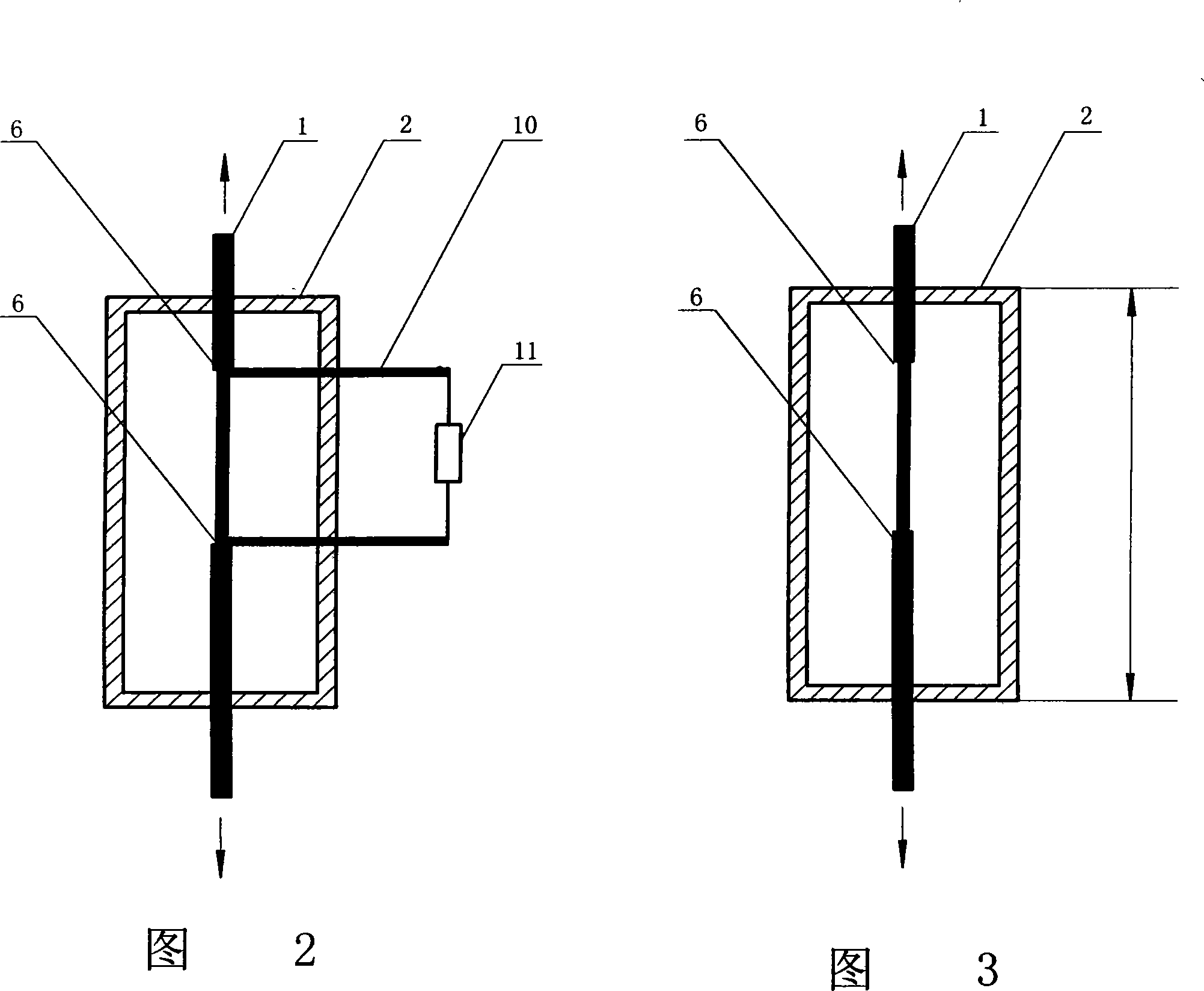

[0031] As shown in Figure 1, the support 7 is first set up firmly at a safe position of 2-5m away from the heating furnace 2, preferably 5m, and the digital camera 3 is installed on the support 7, and the viewfinder frame of the digital camera 3 is aligned vertically The object being photographed, to increase the shooting accuracy, and its video output is connected to the computer 4 . Thereafter, the position of the digital camera 3 remains unchanged. Offer two diameters on the heating furnace 2 furnace walls and be 15-30mm, preferably the observation hole 5 of 20mm, the distance between the hole centers is 30-50mm, preferably 40mm. Make two marks 6 on the test piece 1 facing the observation hole 5 on the furnace wall. The marks 6 are hoops, small holes or visible marks, and the mark spacing is preferably 40mm. In the test, a digital camera 3 can be used to clearly capture an image with a fixed size, which includes two observation holes 5 provided on the furnace wall of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com