Fiber compressive and flexural property measuring method and device

A technology of compression bending and fiber, applied in the field of compression, tensile property measurement and bending of high-performance fibers or fibrous substances, which can solve the problems of small and difficult fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

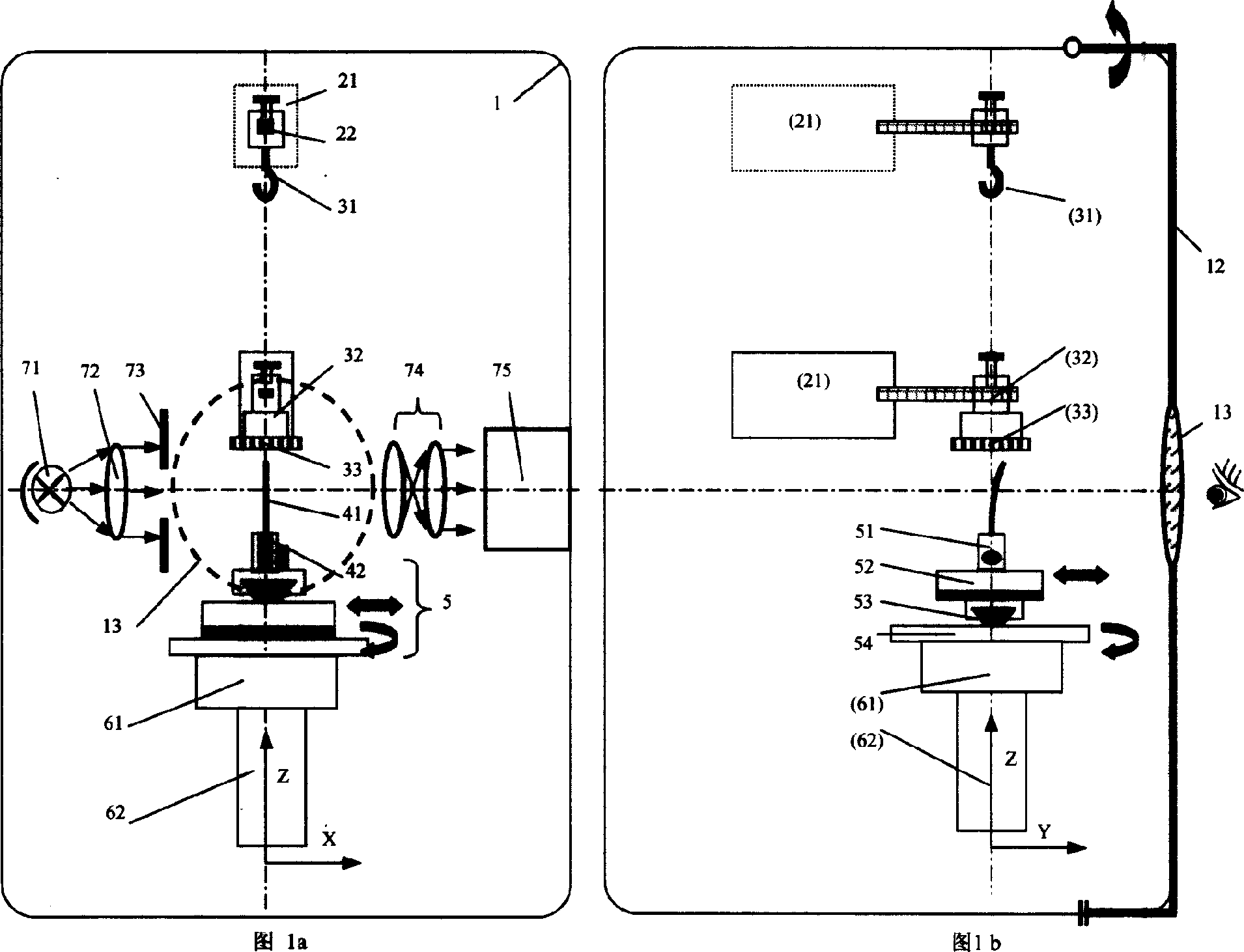

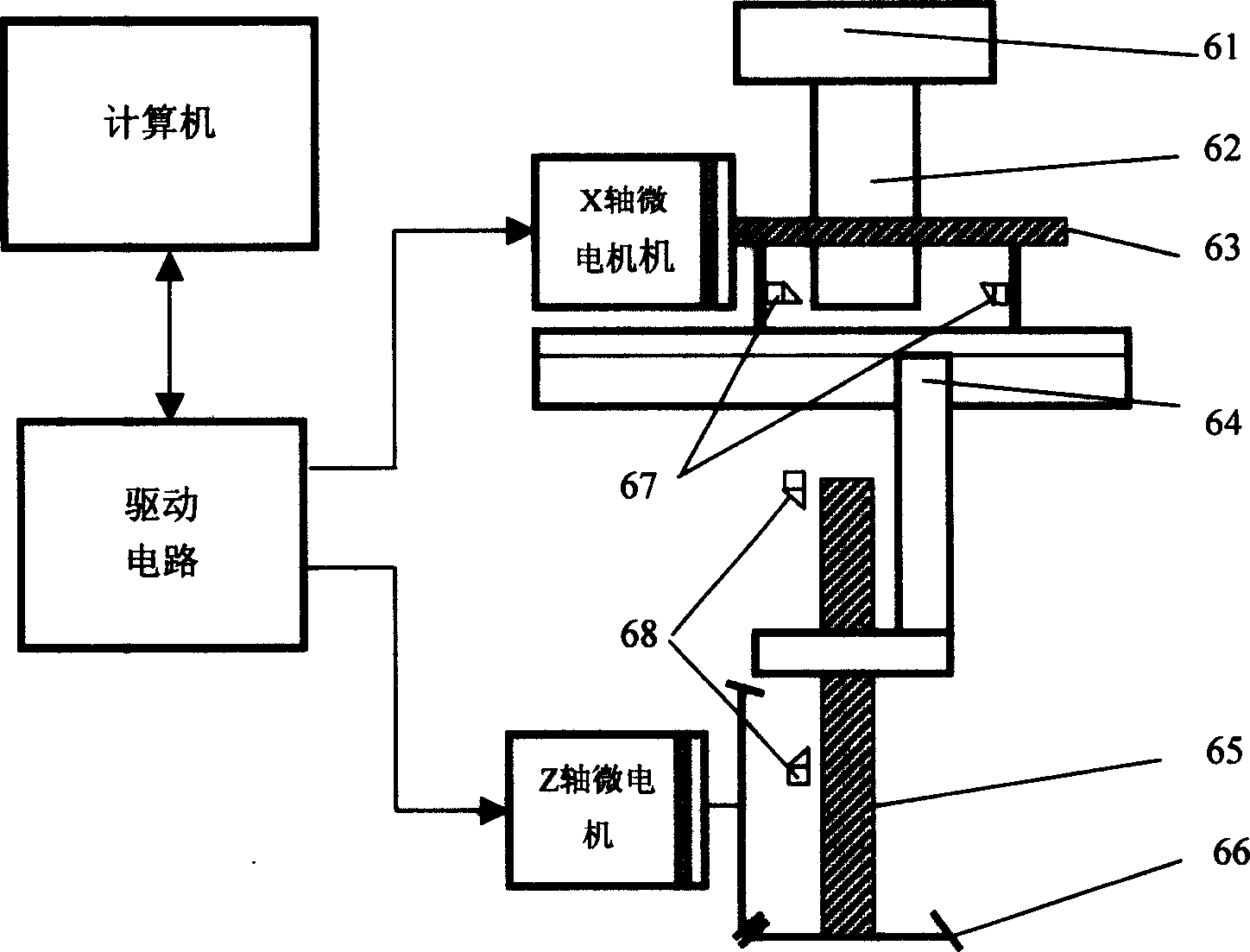

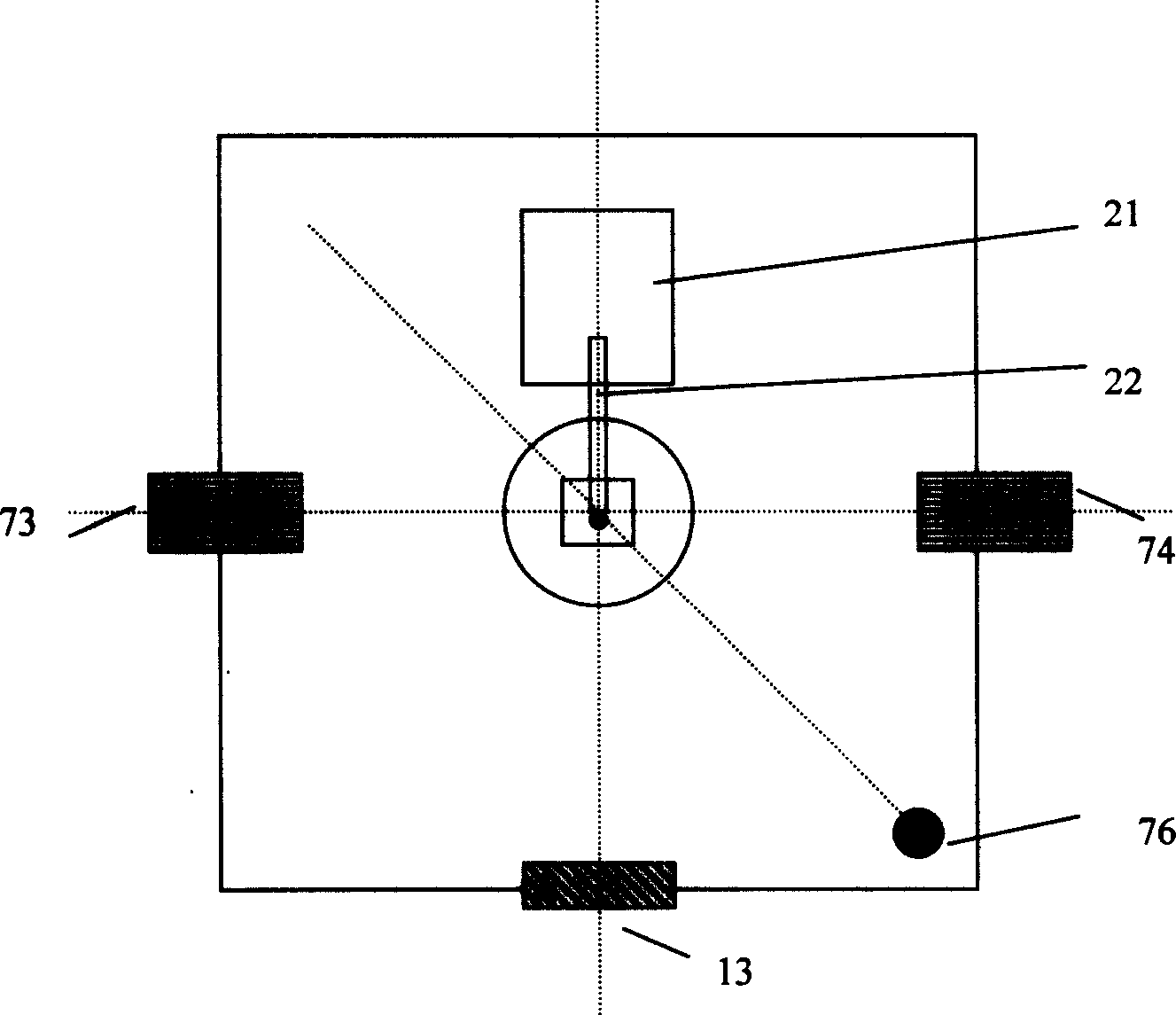

[0062] The present invention will be further described below in conjunction with accompanying drawing.

[0063] The present invention is a kind of method that is used for fiber compression bending property measurement:

[0064] ① Obtain a fiber sample through the sample preparation template 43 - fiber needle 41;

[0065] ②In order to reduce the influence of air flow and vibration on the measurement, the entire measurement process of fiber axial compression performance is completed in a measurement chamber 1, and the steps are:

[0066] a. Select the upper clamp 32 for multi-functional compression and its membrane surface simulation material 33 and adjust the clamping method; the lower clamp 5 completes the vertical holding of the fiber needle 41 .

[0067] b. Roughly estimate the center position of the X-axis of the fiber needle 41 through the observation of the magnifying glass 13 mounted on the openable transparent panel at the front of the measurement cavity 1 .

[0068] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com