Device and method for testing mechanical properties of pile-soil contact surface

A technology for testing device and mechanical properties, which is applied in the direction of measuring device, strength properties, and testing material strength by applying stable tension/pressure, can solve the problems of geotechnical instruments not being able to study the pile-soil contact surface test, etc., and achieve simple structure, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

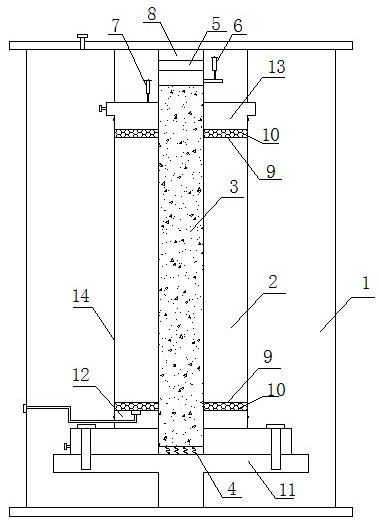

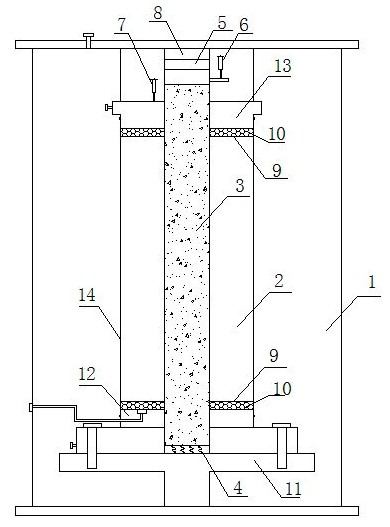

[0031] Such as figure 1 , as shown, a pile-soil contact surface mechanical properties testing device, its structure includes a sealed pressure chamber (1), a hollow cylindrical soil sample (2), a solid cylindrical concrete pile sample (3), it is characterized in that the solid The cylindrical concrete pile sample (3) is prefabricated, and its diameter is equal to the inner diameter of the hollow cylindrical soil sample (2), and the two closely fit; the lower end of the concrete pile sample (3) is placed on the base ( 11), the upper end is connected to the pressure loading system through the dowel bar (8), and the stress sensor (5) and the displacement sensor I (6) are set on the dowel bar (8); the outer side of the concrete pile sample (3) is a hollow cylinder Soil sample (2), filter paper (9) and permeable stone (10) are placed on the lower end of soil sample (2) and placed on the base (12), and filter paper (9), permeable stone (10), The top cover (13) and the displacement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com