Composite enhanced hydrolysis-resistant thermoplastic polyurethane elastomer and its preparation method

A technology of thermoplastic polyurethane and plastic polyurethane, which is applied in the field of composite reinforced hydrolysis-resistant thermoplastic polyurethane elastomer and its preparation, and can solve the problems of performance degradation of polyurethane elastomer, large addition amount, low reactivity of epoxy components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

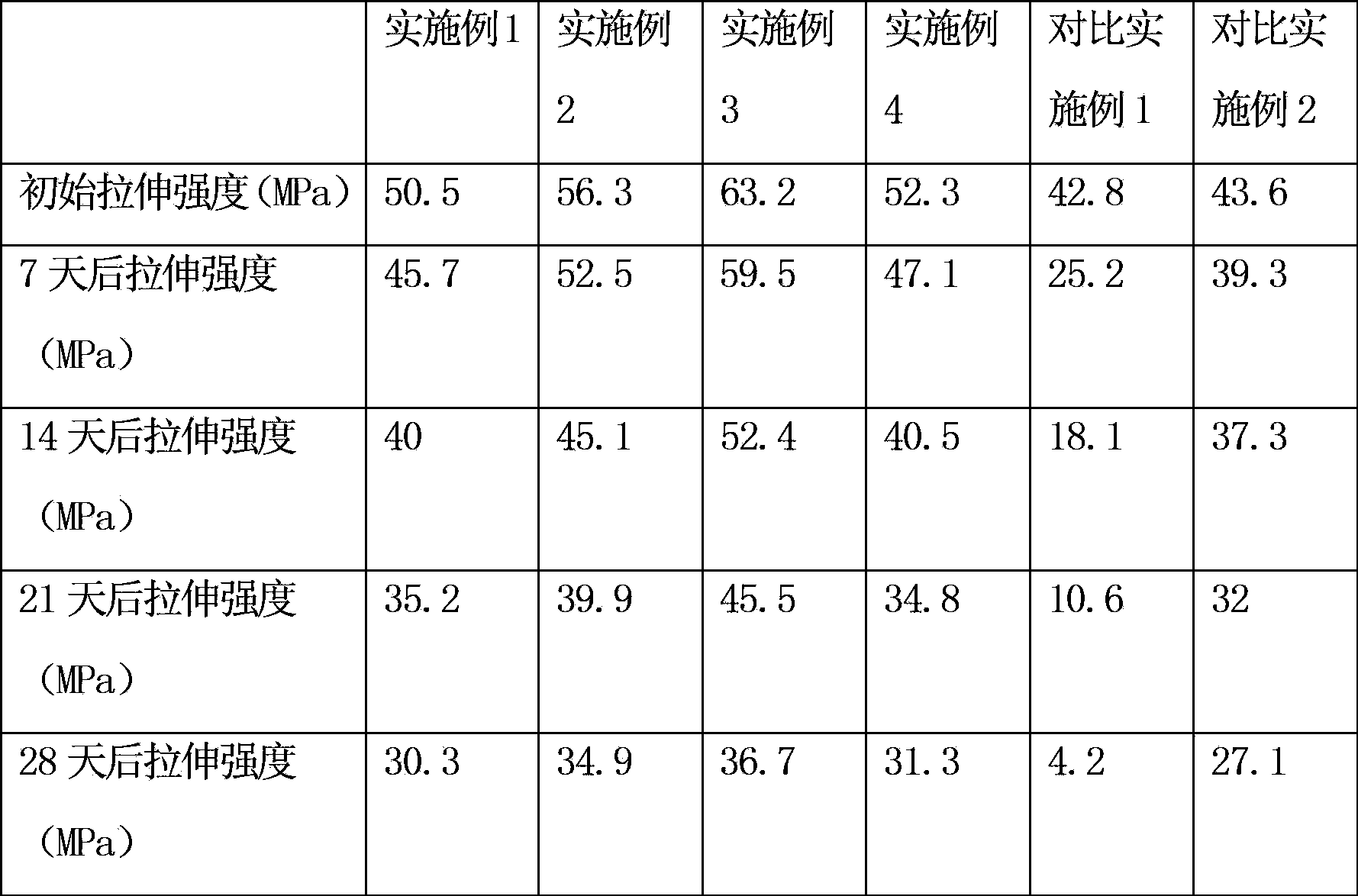

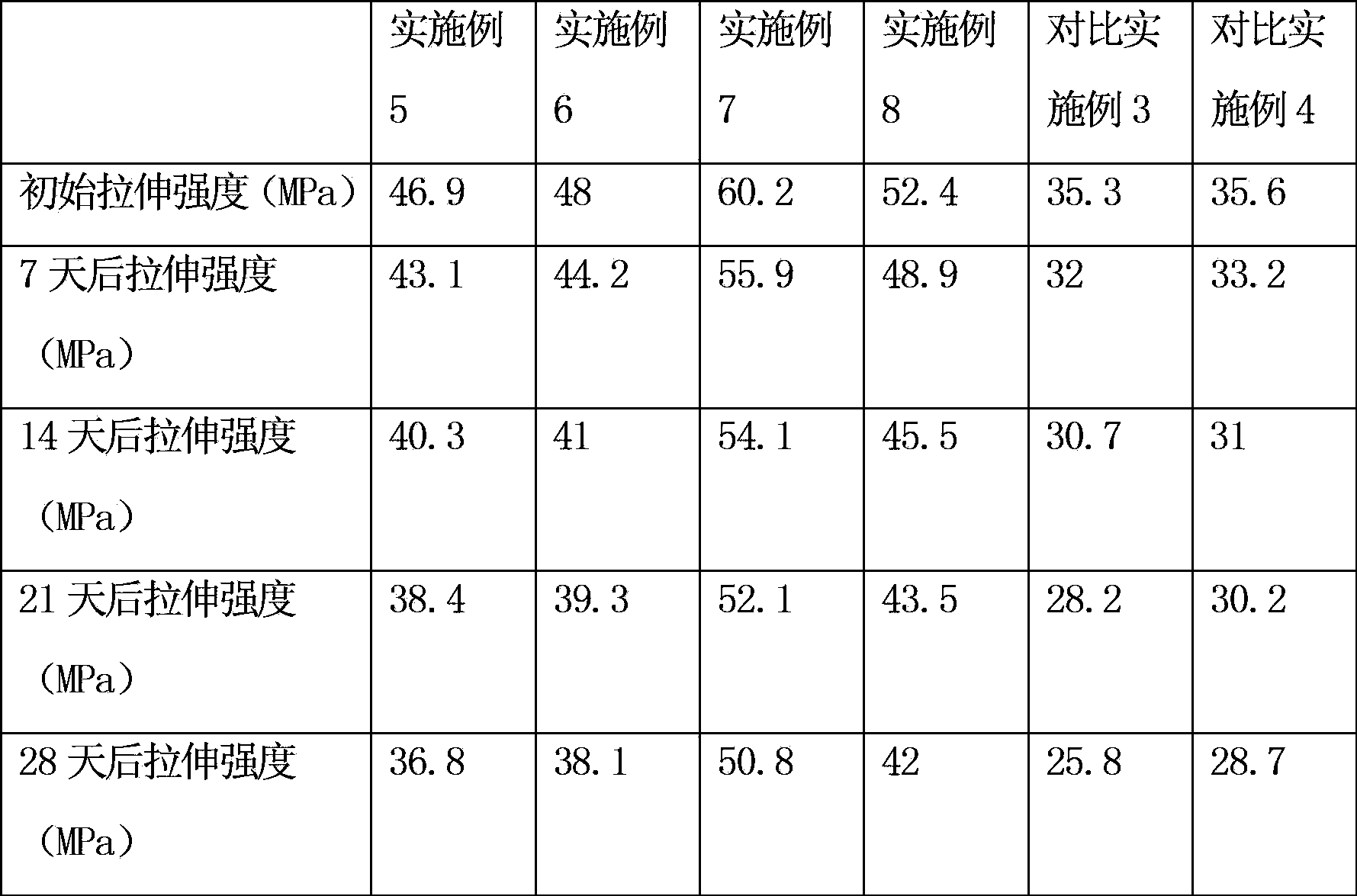

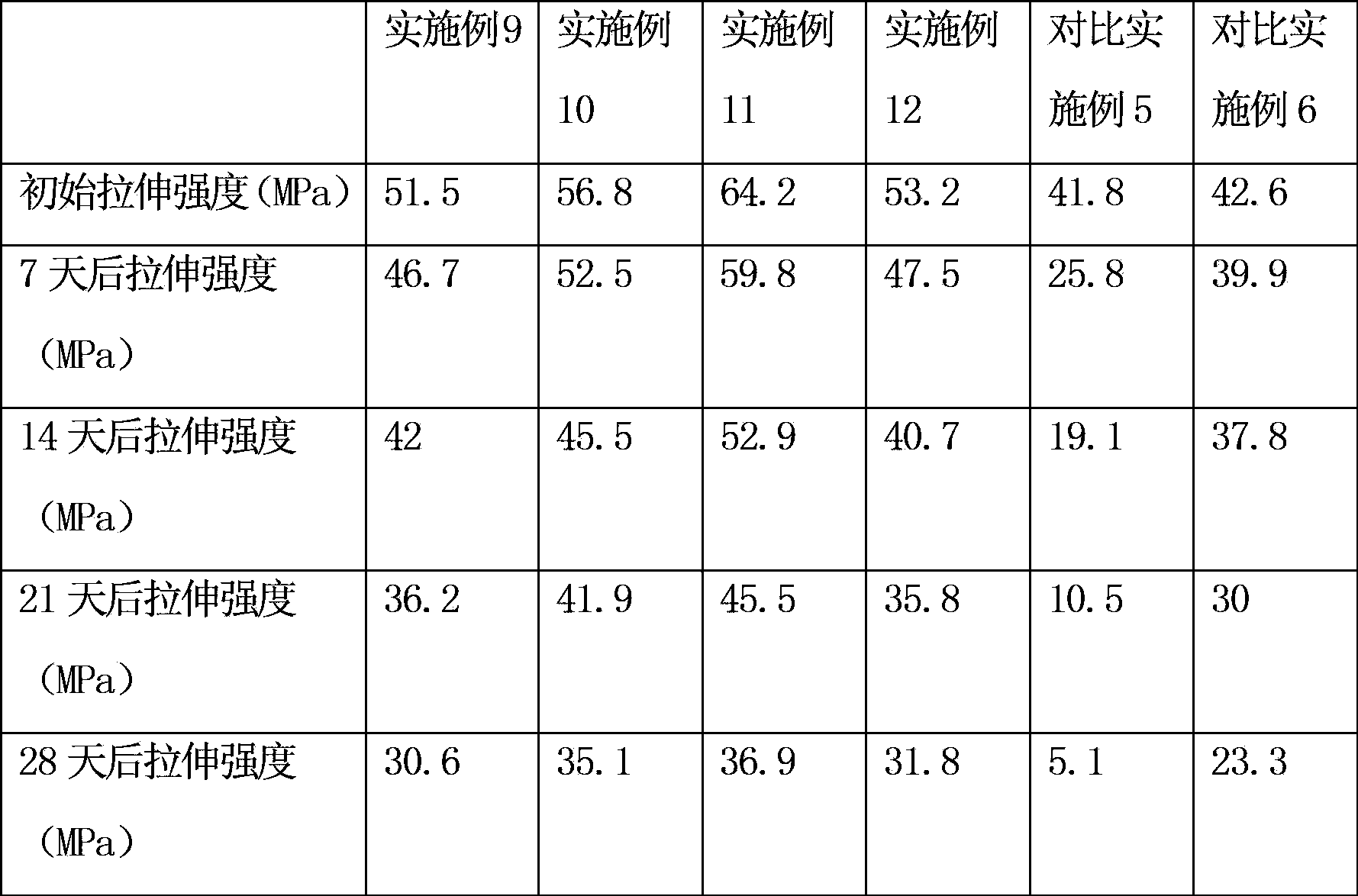

Embodiment 1

[0093] Components A and C are the same as in Comparative Example 1, and 5% KH560-coated nano-silica is added to Component B on the basis of Comparative Example 1, and the preparation process is the same as in Comparative Example 1.

Embodiment 2

[0095] Components A and C are the same as in Comparative Example 1, and 8% KH560-coated nano-silica is added to Component B on the basis of Comparative Example 1, and the preparation process is the same as in Comparative Example 1.

Embodiment 3

[0097] Components A and C are the same as in Comparative Example 1, and 12% KH560-coated nano-silica is added to Component B on the basis of Comparative Example 1, and the preparation process is the same as in Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com