Quantitative testing method for microscopic strengths of mixture-mineral aggregate contact surfaces

A test method and meso-strength technology, which is applied in the field of quantitative testing of the meso-strength of the contact surface of mixed materials and minerals, can solve the problems of individual differences, inability to achieve quantitative testing, and difficulty in mastering test skills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

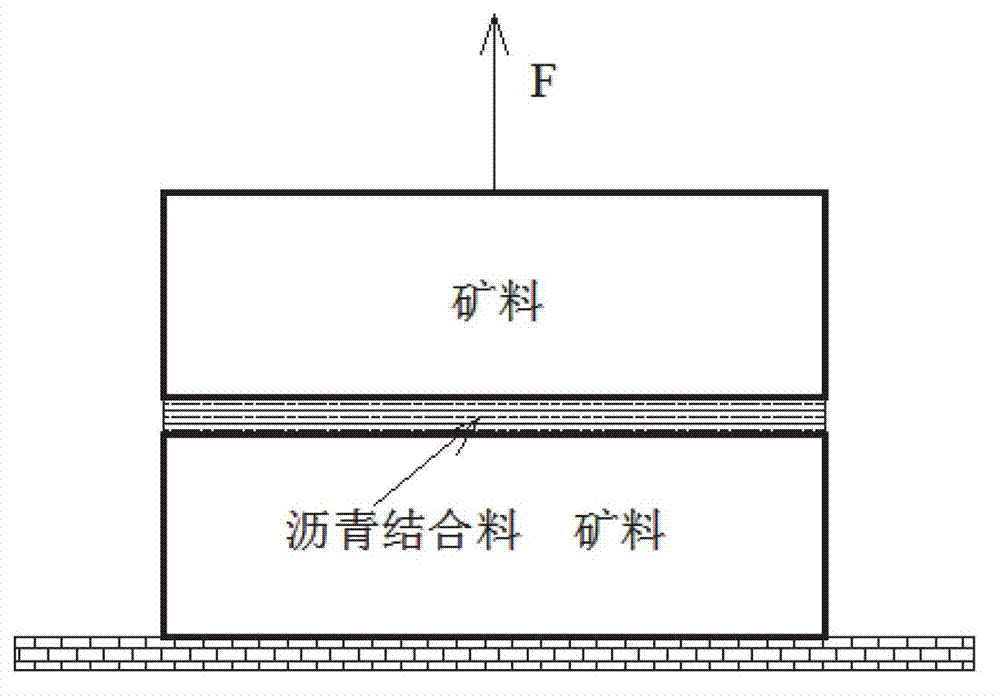

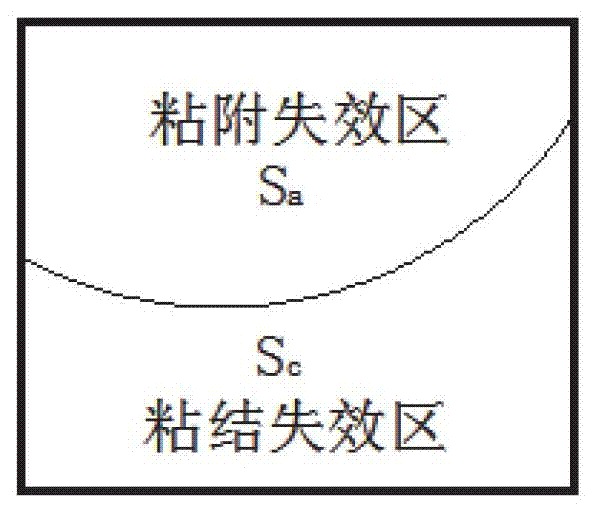

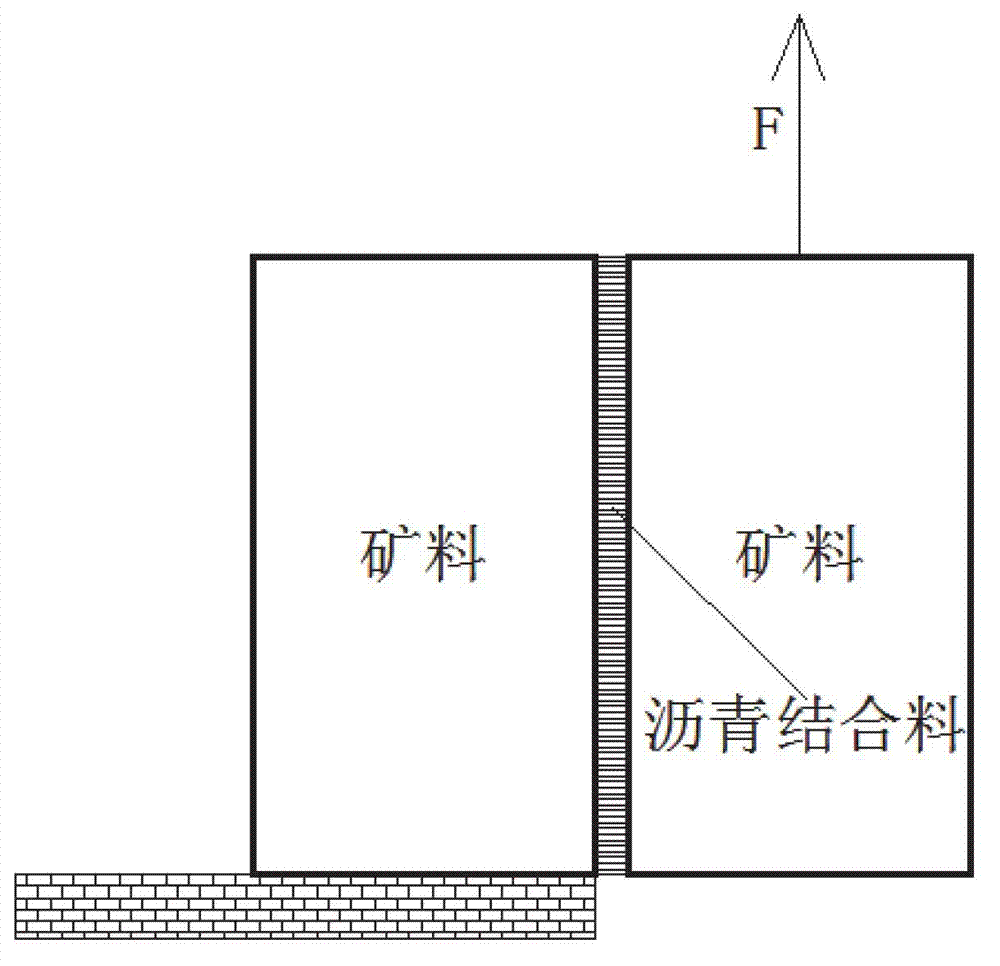

[0033] The inventive idea of the present invention is: the destruction of the contact surface of the mineral material is the most fundamental form of the phase separation of the mineral material particles in the mixture and thus the damage. There are two types of failure on the contact surface of mineral aggregates. One is that the asphalt is peeled off from the surface of mineral aggregates to cause adhesion failure on the surface of asphalt aggregates; the other is that the asphalt binder itself cracks and causes binder failure. The two failure states correspond to the bonding strength between asphalt aggregates and the bonding strength of the asphalt binder itself, respectively. The failure mode has a great correlation with the test temperature, the thickness of the oil film on the contact surface, and the properties of the asphalt. The adhesion strength between asphalt aggregates and asphalt binder itself is also closely related to mechanical effects, temperature, oil fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com