Method for formulating water-air alternate time-controlled quenching process

A cooling process and air-to-air alternation technology, which is applied in quenching agents, manufacturing tools, heat treatment equipment, etc., can solve problems such as fire, low mechanical properties of oil quenching, oil quenching oil fume pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Adopt a kind of method described in the present invention to formulate water-air alternate time-controlled quenching and cooling process to process the long axis of Ф200mm of medium-carbon alloy steel as the material, and require the surface to be halfway to the center (50mm away from the surface) after quenching The obtained structure is 50% martensite and bainite and 50% pearlite and ferrite; the medium used in the water-air alternating time-controlled quenching and cooling process is water and air, and the specific steps include:

[0030] The first step is to determine the performance testing site and the organizational requirements for the testing site;

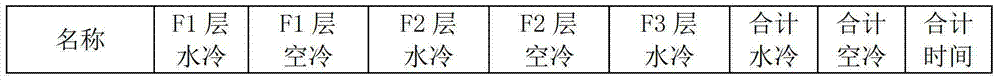

[0031] The second step, combined with the continuous cooling transformation curve (CCT) of supercooled austenite in medium carbon alloy steel, in order to obtain the expected structure at the position 50mm away from the surface of the long-axis section of Ф200mm, it should be from the surface to the position 50mm aw...

Embodiment 2

[0050] Adopting a method of formulating water-air alternate time-controlled quenching and cooling process according to the present invention to process 718 plastic mold steel with a thickness of 300mm, it is required that the structure from the surface to the center after quenching is bainite and a small amount of retained austenite; The media used in the water-air alternately controlled quenching and cooling process are water and air, and the specific steps are as follows:

[0051] The first step is to estimate the continuous cooling transformation curve (CCT) of supercooled austenite in 718 steel, and reduce the temperature of the entire section (surface to core) to below 600°C within 2600S to obtain the required structure. ;

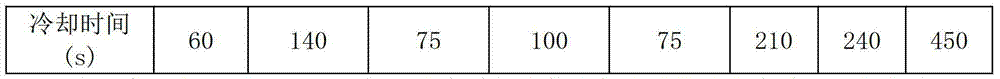

[0052] In the second step, since the structure from the surface to the center after quenching is required to be bainite and a small amount of retained austenite, the 718 plastic mold steel is divided into control cooling rate areas from the surface to...

Embodiment 3

[0061] The H13 mandrel is processed by a method of formulating a water-air alternate time-controlled quenching and cooling process described in the present invention. It is required that the mechanical properties at a distance of 1 / 2R (R is the radius of the axis) from the surface after treatment should be higher than the specified value. The quenching medium adopts polymer water-soluble medium and air.

[0062] According to the method of Example 1, a water-air alternate time-controlled quenching and cooling process was developed.

[0063] After processing according to this process, the performance of the product meets the requirements, and there is no crack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com