Aging-reinforced titanium-copper alloy and preparation method thereof

A titanium-copper alloy and aging-strengthening technology, applied in the field of copper alloys, can solve the problems of poor weldability and electroplating properties, unsatisfactory effects, and less research on aging precipitation strengthening of titanium-copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

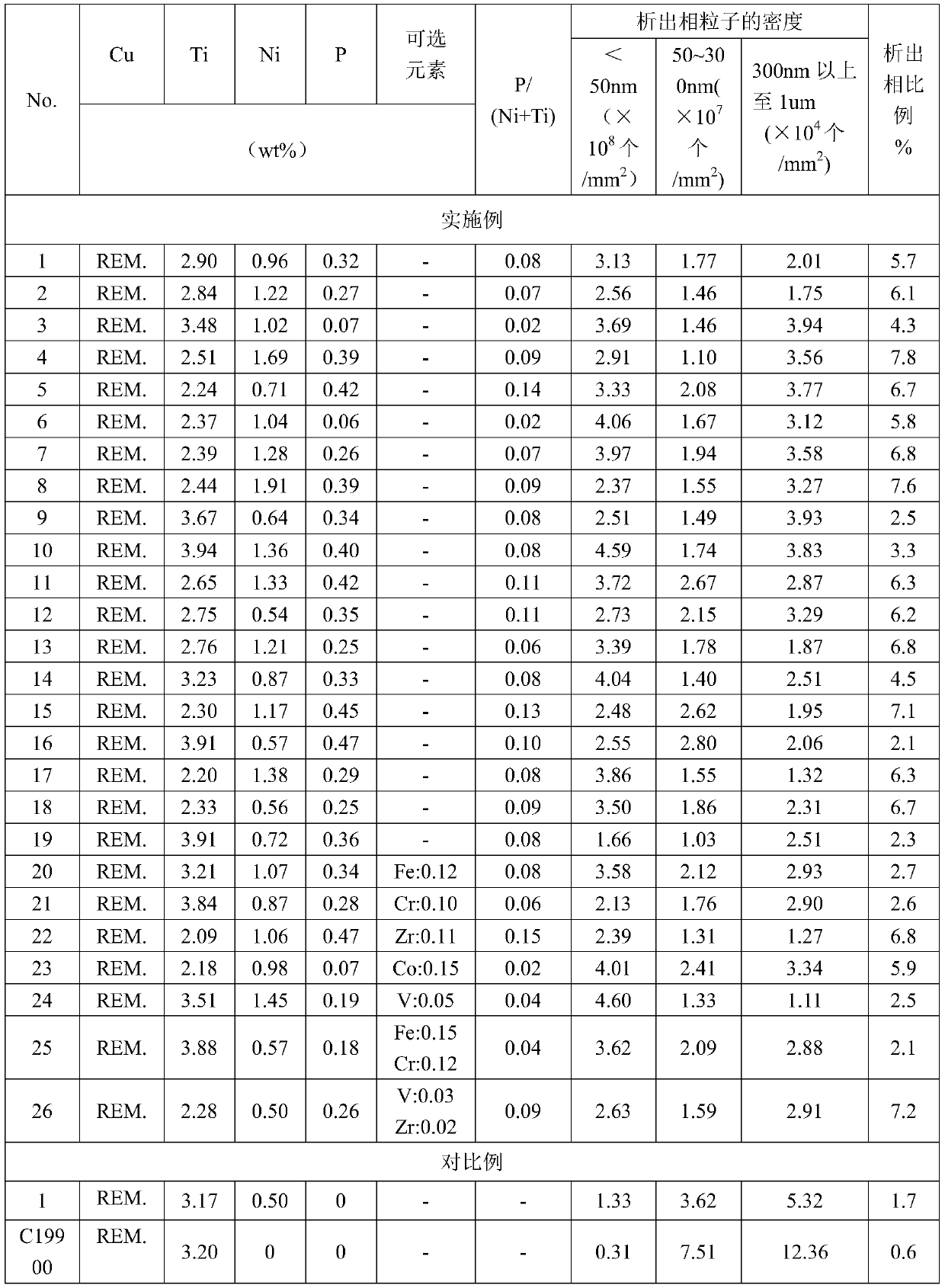

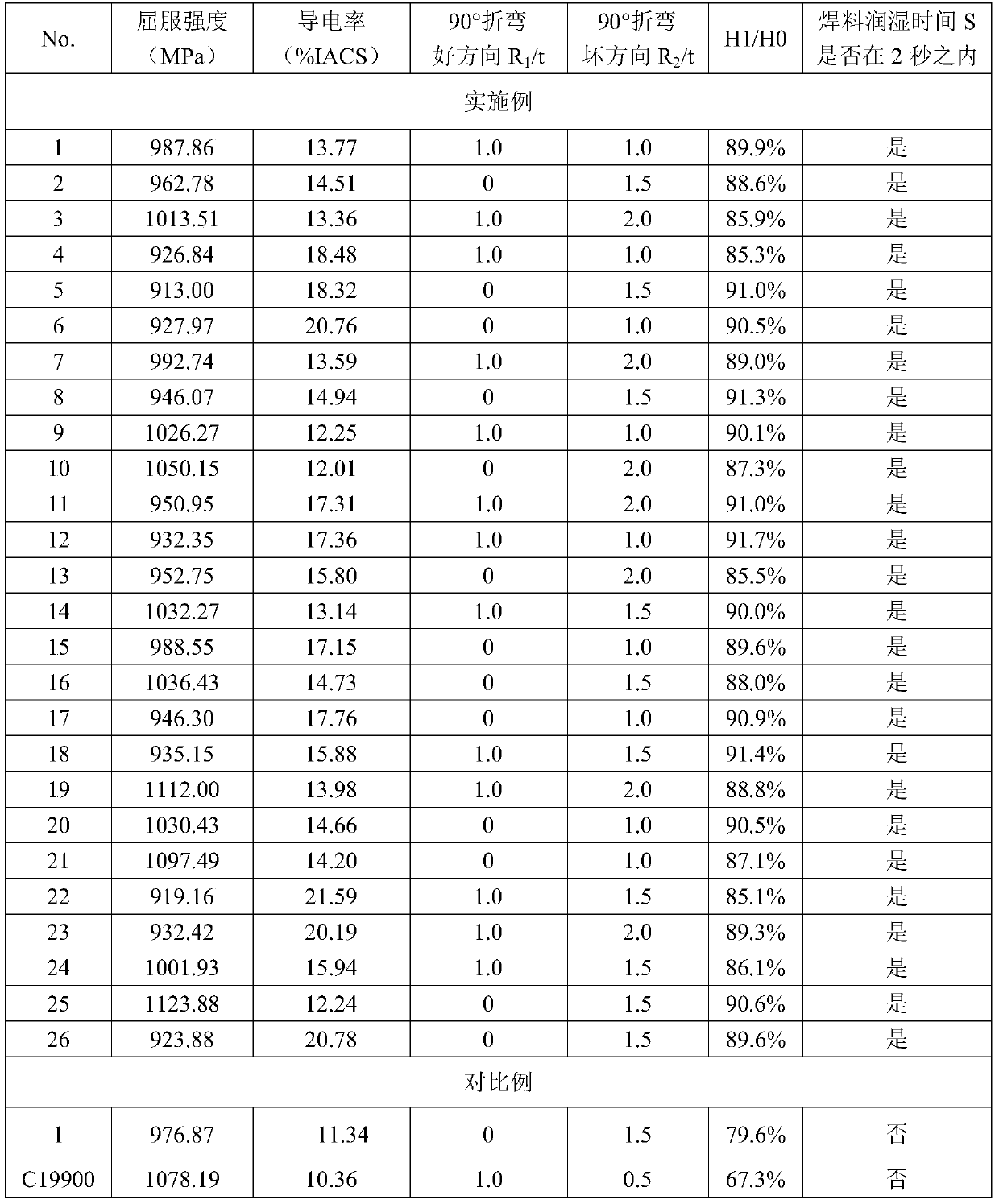

[0063] The present invention will be further described below in conjunction with the embodiments of the present invention.

[0064] When preparing the copper alloy of the embodiment of the present invention, since Ti, Ni, and P are active metals, a vacuum melting furnace is used for melting and casting. In addition, in order to prevent the test results from being affected by the mixing of impurity elements other than the elements specified in the present invention, raw materials with higher purity are used for smelting.

[0065] For the ingot whose composition is Ti, Ni and P in the content listed in Table 1, and the rest is copper and unavoidable impurities, after heating at 950°C for 3 hours for homogenization and annealing, the processing rate shall not be less than 90%. Carry out hot rolling to obtain a hot-rolled plate with a thickness of no more than 16mm. After surface cutting and peeling, perform the first cold rolling treatment at a processing rate of not less than 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com