Method for refining crystal grains of magnesium alloy plate

A technology for refining grains and magnesium alloy plates, which is applied in the field of preparation of magnesium alloy grains through multiple cycles of "cold rolling-annealing" method, can solve the problems that are not suitable for commercial production, and achieve fine grains , refined grain size, high strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

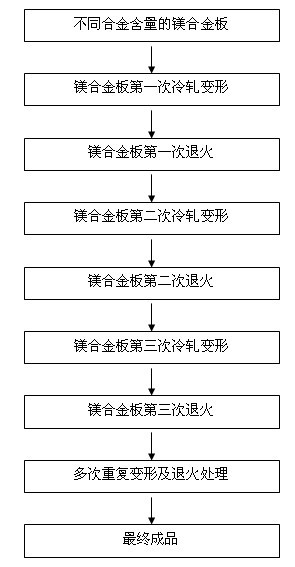

[0035] Embodiment 1 The preparation process of magnesium alloy sheet grain refinement is as attached figure 1 As shown, a 2mm thick AZ31 magnesium alloy sheet is used. First, the magnesium alloy sheet is homogenized, heated to 350°C and kept for 6 hours. The metallographic microscope shows that the grain size is 80μm; the processed magnesium alloy sheet is cooled Rolling, the rolling speed is 20m / min, the amount of deformation (rolling amount) is 10%, and a plate with a thickness of 1.8mm is obtained; then the cold-rolled plate is annealed, and the annealing process is 350°C for 0.5 hours. Observe the grain size of the sample with a metallurgical microscope. After the first round of cold rolling and annealing, the grain size of the plate is 35μm;

[0036] The AZ31 magnesium alloy sheet prepared above is subjected to the second cold rolling and annealing treatment. First, cold-roll the 1.8mm-thick plate at a rolling speed of 20m / min and a reduction of 15% to obtain a plate with a ...

Embodiment 2

[0038] Using 1mm thick AZ31 magnesium alloy sheet, the magnesium alloy sheet is first homogenized, heated to 400℃ and kept for 12 hours, the metallographic microscope shows that the grain size is 100μm; the processed magnesium alloy sheet is cold rolled and rolled The production speed is 15m / min, the rolling reduction is 12%, and a sheet with a thickness of 0.88mm is obtained; then the cold-rolled sheet is annealed, the annealing process is 300°C for 0.5 hours, and the sample is observed with a metallographic microscope The grain size, the grain size of the plate obtained after the first round of cold rolling and annealing is 30 μm.

[0039] The AZ31 magnesium alloy sheet prepared above is subjected to the second cold rolling and annealing treatment. First, cold-roll a 0.88mm thick plate at a rolling speed of 25m / min and a rolling reduction of 15% to obtain a plate with a thickness of 0.75mm; then the cold-rolled plate is annealed with an annealing process of 280 The temperature...

Embodiment 3

[0041] Using 2mm thick AZ61 magnesium alloy sheet, the magnesium alloy sheet is homogenized first, heated to 400°C and kept for 12 hours, the metallographic microscope shows that the grain size is 60μm; the processed magnesium alloy sheet is cold rolled and rolled The production speed is 12m / min, the rolling reduction is 8%, and a plate with a thickness of 1.84mm is obtained; then the cold-rolled plate is annealed, and the annealing process is 310℃ for 0.5 hours. The sample is observed with a metallurgical microscope The grain size, the grain size of the plate obtained after the first cold rolling and annealing is 35 μm.

[0042] The AZ61 magnesium alloy sheet prepared above is subjected to the second cold rolling and annealing treatment. First, cold-roll a 1.84mm thick plate at a rolling speed of 20m / min and a rolling reduction of 12% to obtain a plate with a thickness of 1.62mm. Then, the cold-rolled plate is annealed with an annealing process of 270 The temperature is kept fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com