Dual-purpose heat pump device for winter and summer

A technology of dual-use in winter and summer, heat pump device, applied in heat pump, lighting and heating equipment, compressor with reversible cycle, etc., can solve the problems of inability to recover low-temperature waste heat, performance degradation of heat pump device, etc., to reduce energy consumption and improve performance , to avoid mutually canceling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

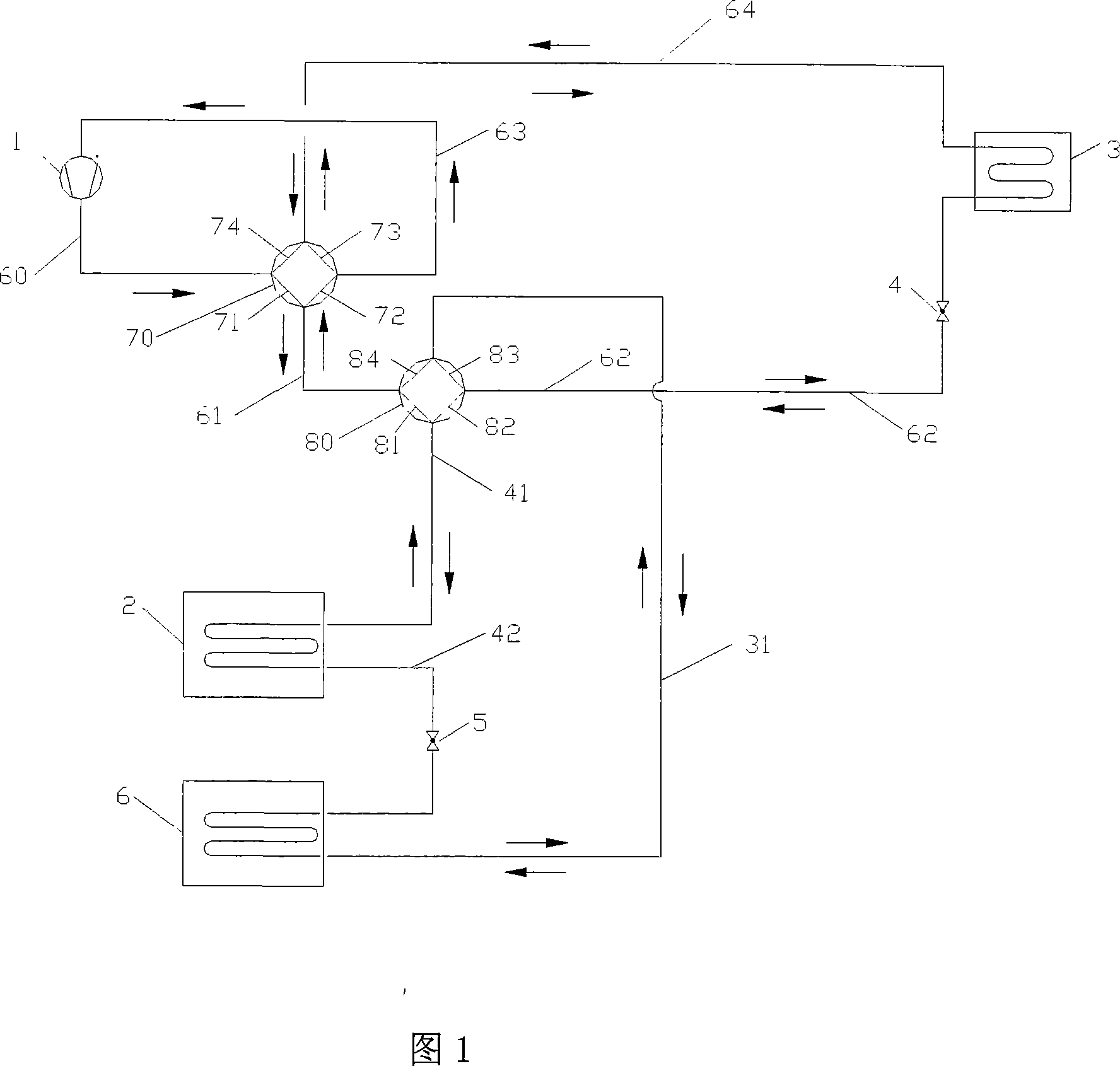

[0047] As shown in Figure 1, the whole device includes the following equipment: compressor 1, heat source side heat exchanger 2, user side heat exchanger 3, throttling mechanisms 4 and 5, second heat exchanger 6, four-way valves 70 and 80 .

[0048] Four passages 71, 72, 73, 74 are provided inside the first four-way valve 70, and four passages 81, 82, 83, 84 are also provided inside the second four-way valve 80; there are four passages outside each four-way valve. Connection points, each connection point is connected to two internal channels. The user-side heat exchanger 3 is a refrigerant-air heat exchanger.

[0049] The heat source side heat exchanger 2 and the second heat exchanger 6 are also refrigerant-air heat exchangers, they can be installed separately; they can also be installed in the same shell, and the air is provided by at least one air-driven device for transporting air A device can be a blower or a fan.

[0050] Throttle mechanisms 4 and 5 are electronic expa...

Embodiment 2

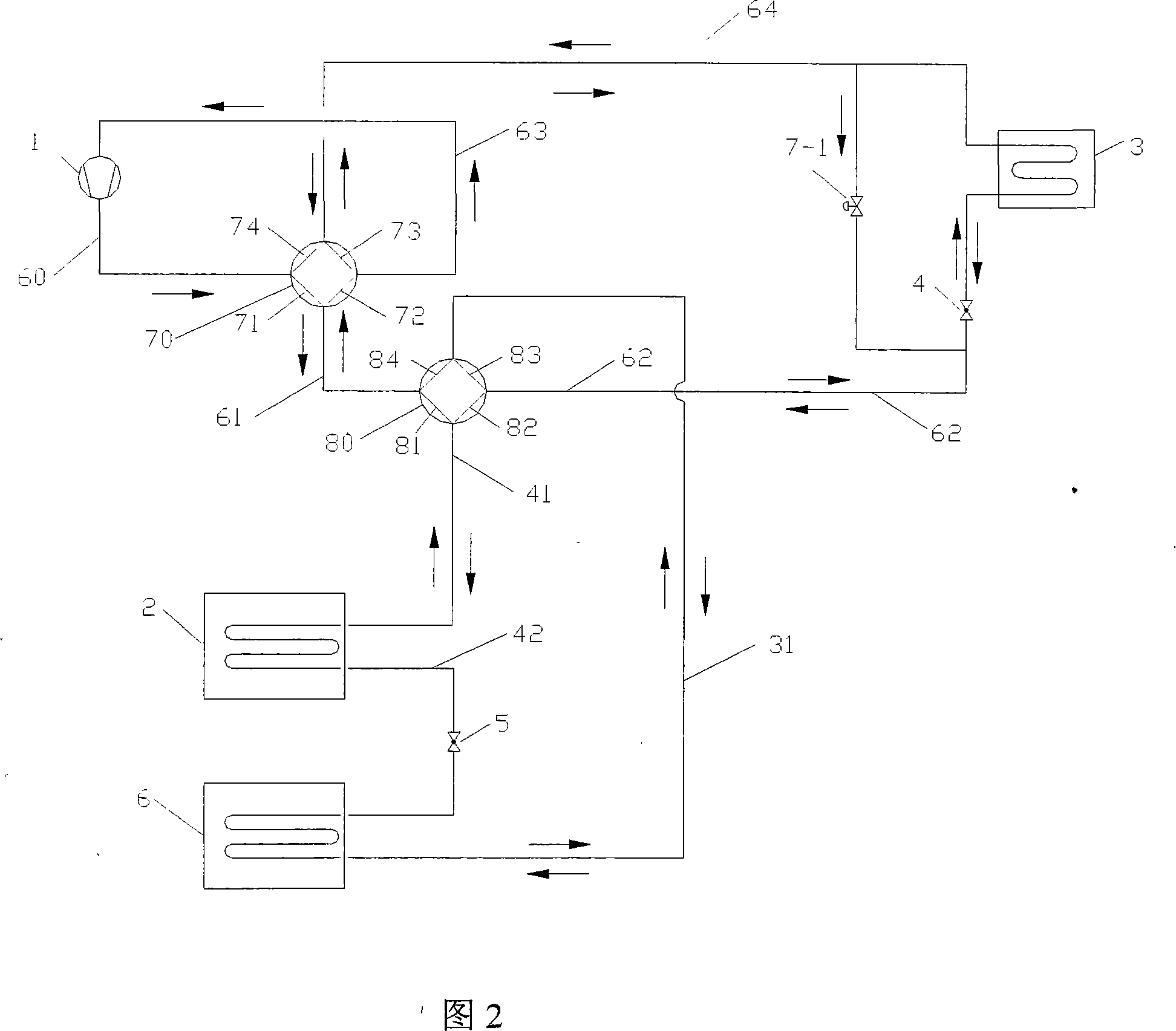

[0066] As shown in FIG. 2 , the heat exchanger 3 on the user side, the heat exchanger 2 on the heat source side, and the second heat exchanger 6 are all refrigerant-air heat exchangers. Compared with Embodiment 1, the only difference is that the first flow direction control valve 7-1 is added, which is connected in parallel with the user-side heat exchanger 3 and the throttling mechanism 4, while other equipment and connection methods in the device are the same as Example 1 is exactly the same.

[0067] During the working process of the cooling cycle in summer and the heating cycle in winter in embodiment 2, the first flow direction control valve 7-1 is closed, so the working process of the cooling and heating cycle in embodiment 2 is exactly the same as that in embodiment 1.

[0068] During the working process of the winter defrosting cycle in Embodiment 2, the first flow direction control valve 7-1 is opened, and the throttling mechanism 4 is closed. Therefore, during the de...

Embodiment 3

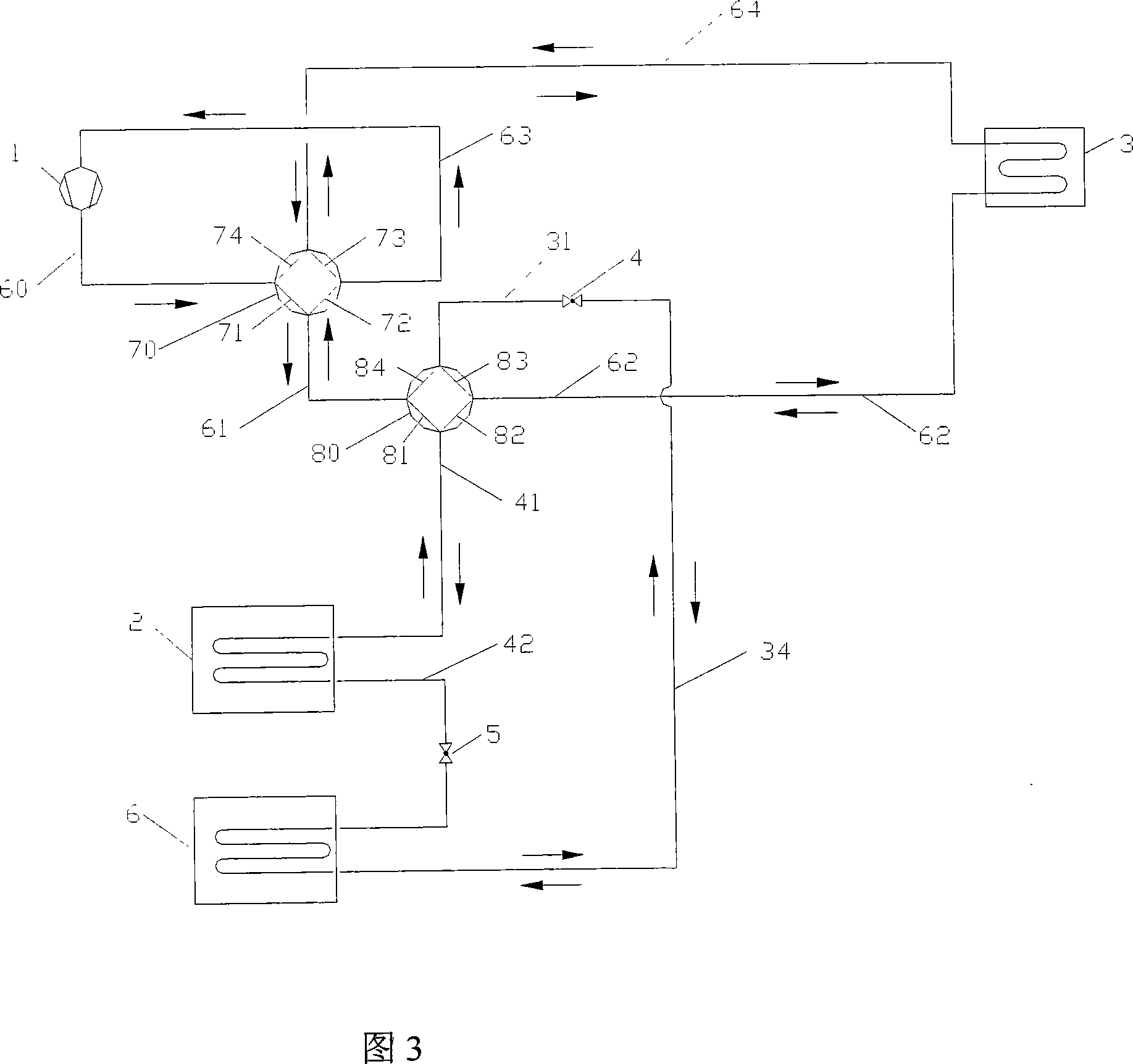

[0071]As shown in FIG. 3 , the user-side heat exchanger 3 , the heat source-side heat exchanger 2 , and the second heat exchanger 6 are all refrigerant-air heat exchangers. The difference between it and Embodiment 1 is: in Embodiment 1, the throttling mechanism 4 is set on the pipe connecting the second four-way valve 80 and the user-side heat exchanger 3; but in Embodiment 3, the throttling mechanism 4 is set on the pipe connecting the second four-way valve 80 and the second heat exchanger 6 .

[0072] Apart from that, in Embodiment 3, other devices are connected in the same way as in Embodiment 1. When working, the circulation loops of the summer refrigeration cycle, the winter heating cycle and the winter defrosting cycle and the functions of each device are also the same as those in Embodiment 1.

[0073] In the process of implementation, there is also the following scheme: one end of the throttling mechanism 4 is connected to the passage (81, 82) of the second four-way v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com