Phase change energy storage microcapsule and preparation method thereof

A phase change energy storage, microcapsule technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of reducing paraffin utilization efficiency, reducing heat conduction efficiency, wasting heat energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

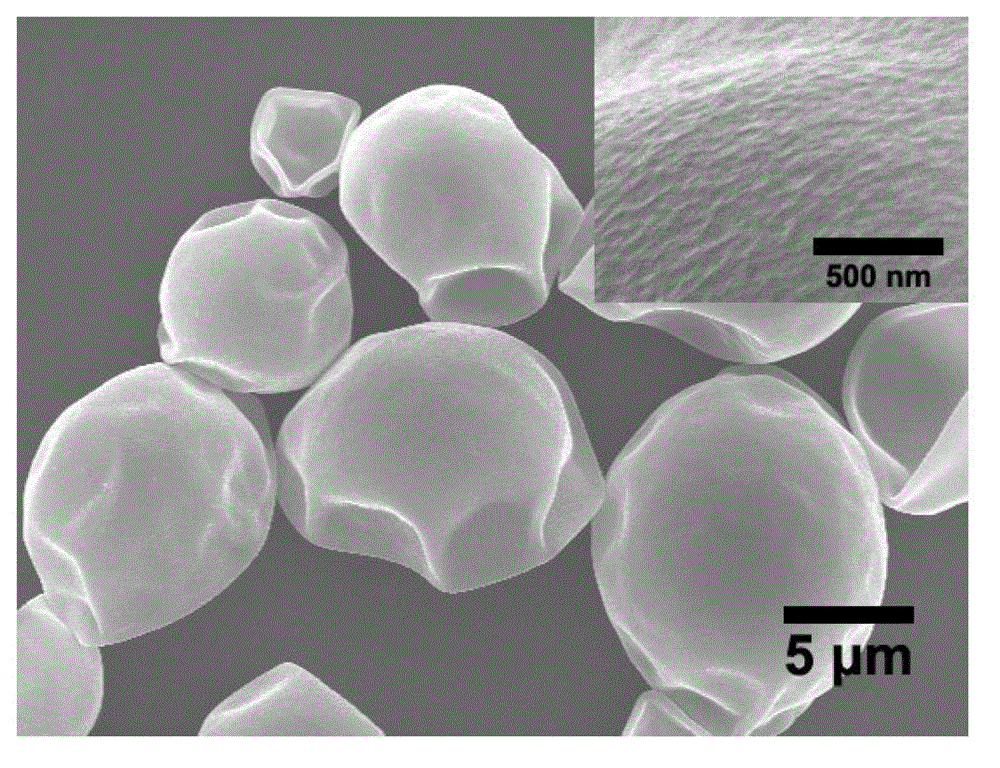

[0039] The preparation method of the phase change energy storage microcapsules of the present invention comprises the following steps:

[0040]Perform emulsion polymerization reaction of paraffin and monomer styrene in the presence of emulsifier, initiator and crosslinking agent to obtain phase change energy storage microcapsules with core-shell structure;

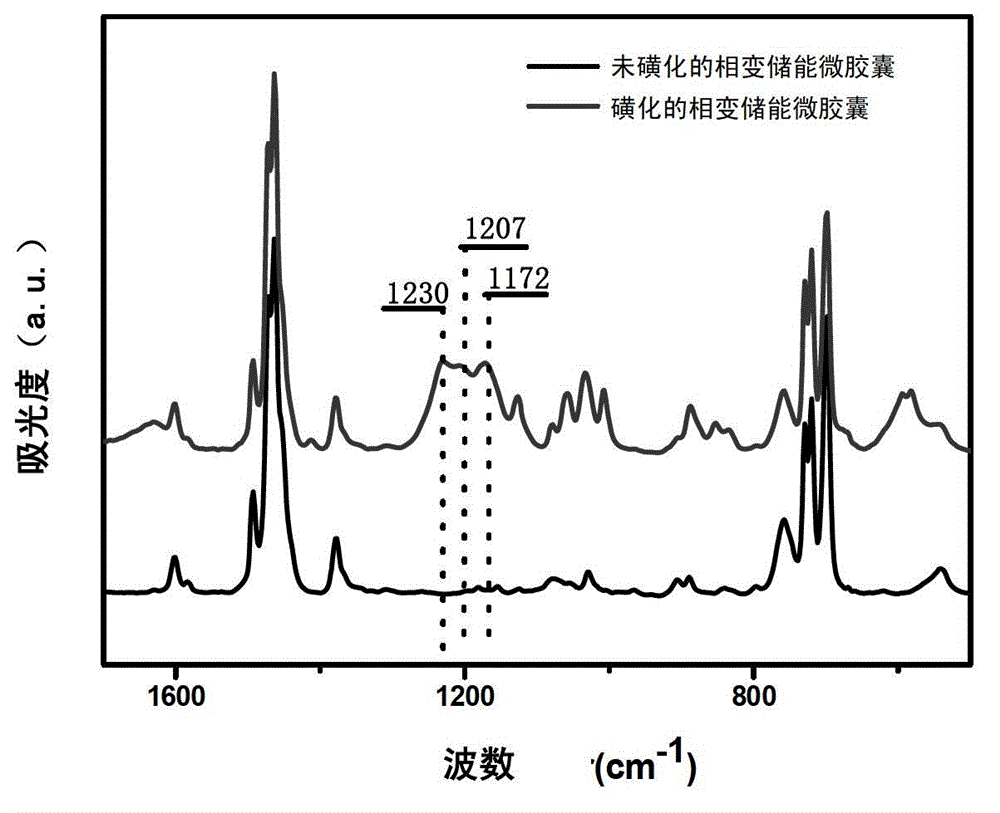

[0041] Reacting the phase-change energy storage microcapsules having a core-shell structure with a sulfonating agent, thereby sulfonating the shell of the phase-change energy storage microcapsules to obtain sulfonated phase-change energy storage microcapsules;

[0042] The reduction reaction of metal ions occurs on the entire shell of the sulfonated phase-change energy storage microcapsules, thereby obtaining the phase-change energy storage microcapsules in which metal or metal oxide particles are compounded on the entire shell.

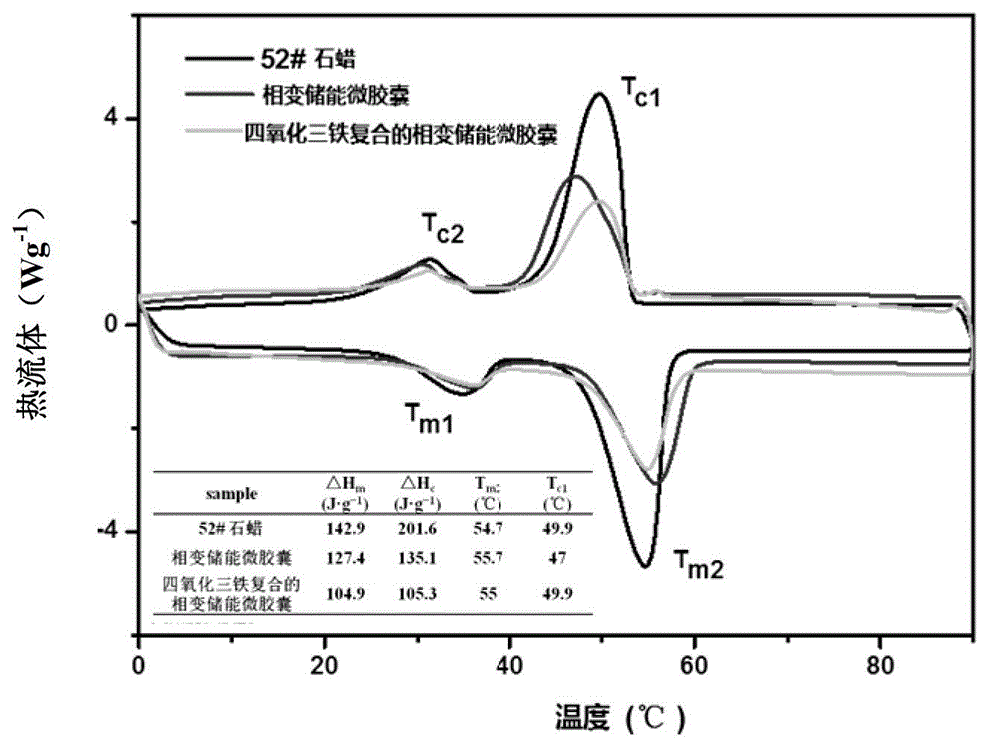

[0043] The phase change material used in the present invention is paraffin. Paraffin has the...

Embodiment 1

[0061] 1. Preparation of phase change energy storage microcapsules with core-shell structure

[0062] In this embodiment, sodium lauryl sulfate is used as an emulsifier, and the melting point of phase-change paraffin is 52°C.

[0063] Add 0.2 g of sodium lauryl sulfate to 85 g of water, and this solution is used as the water phase;

[0064] The phase-change paraffin of 10g, 2g styrene, 1g divinylbenzene, 0.06g as the azobisisobutyronitrile of initiator are mixed, be warmed up to 60 ℃, stir after making them mix uniformly as oil phase;

[0065] Mix the above-mentioned water phase and oil phase, heat up to 70 ° C, and use a high-speed mixer to shear and emulsify for 2 minutes at a speed of 12000 rpm to obtain an oil-in-water emulsion;

[0066] The above-mentioned oil-in-water emulsion was transferred to a preheated reaction kettle, and an inert gas-nitrogen was introduced, mechanically stirred at 200 rpm, and emulsion polymerization was carried out at 70°C for about 8 hours.

...

Embodiment 2

[0082] 1. Preparation of phase change energy storage microcapsules with core-shell structure

[0083]The sodium salt hydrolyzate of the styrene-maleic anhydride alternating copolymer used in this embodiment is an emulsifier, and the melting point of the phase-change paraffin is 52°C.

[0084] 10g of aqueous solution of 10wt% styrene-maleic anhydride alternating copolymer sodium salt was added to 77g of water, and the pH value was adjusted to 4.5 with hydrochloric acid, and this solution was used as the water phase;

[0085] With 10g phase-change paraffin, 2g styrene, 1g divinylbenzene, 0.06g is mixed as the azobisisobutyronitrile of initiator, is warming up to 60 DEG C, stirs after making them mix uniformly as oil phase;

[0086] Mix the above-mentioned water phase and oil phase, heat up to 70 ° C, and use a high-speed mixer to shear and emulsify for 2 minutes at a speed of 12000 rpm to obtain an oil-in-water emulsion;

[0087] The above-mentioned oil-in-water emulsion was tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com