Intelligent cooling system for traction converter of electric multiple unit

A technology for traction converters and cooling systems, applied in cooling/ventilation/heating transformation, modification with gaseous coolant, electrical components, etc., can solve the problem of inability to accurately control the heat transfer process of heat sources and energy utilization in traction converters Low efficiency, constant adjustment of cooling intensity, etc., to improve heat dissipation efficiency and energy utilization efficiency, reduce auxiliary power consumption, and meet energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

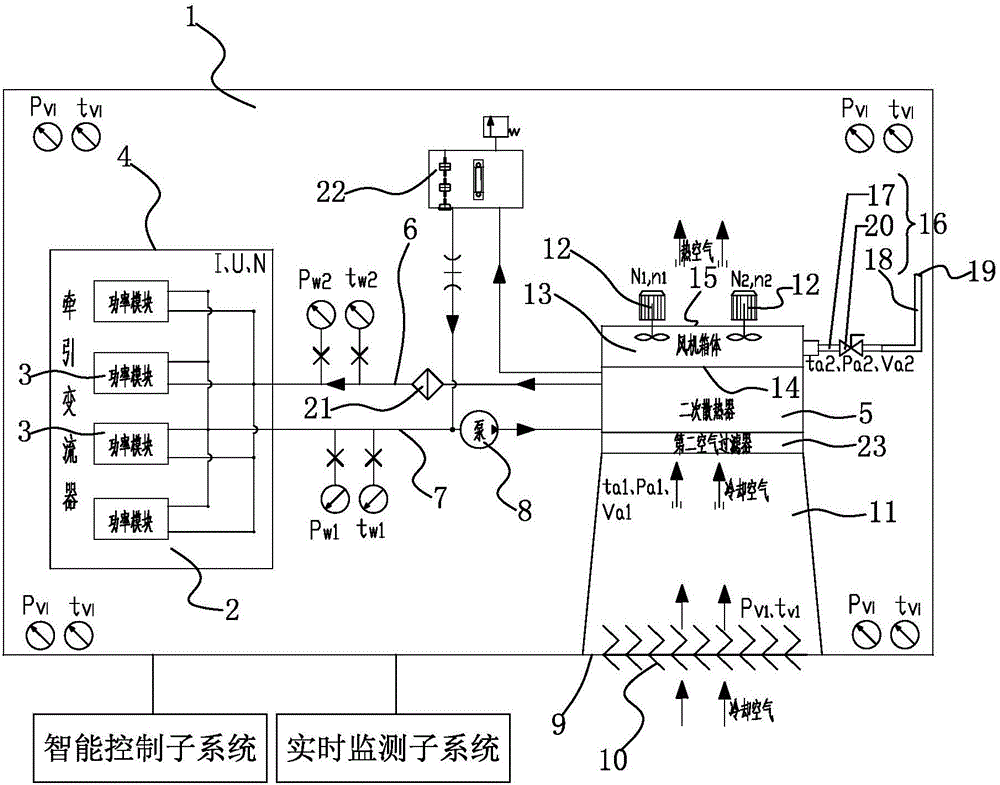

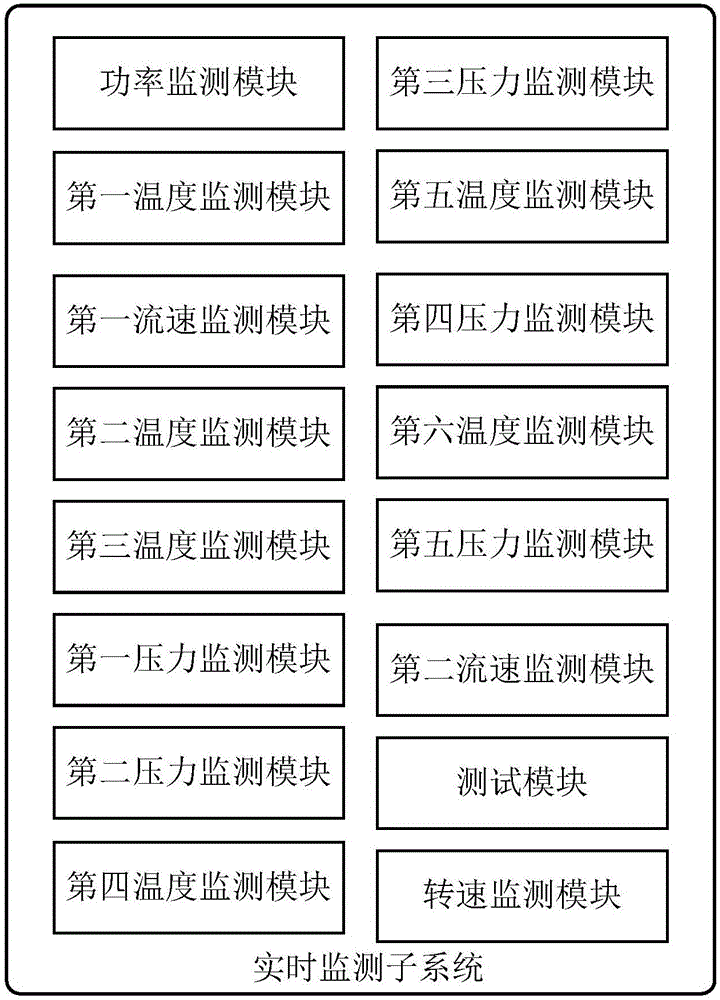

[0048] like figure 1 and figure 2 Shown is an intelligent cooling system for the traction converter of an electric multiple unit, the electric multiple unit has an equipment cabin 1, the traction converter 2 is arranged in the equipment cabin 1, and the cooling system includes: installing the traction The primary radiator 4 of the heat source component 3 included in the converter 2, and the secondary cooling device arranged in the equipment compartment 1; the cooling fluid flowing out of the primary radiator 4 takes away the heat source component 3 to generate heat; the secondary cooling device includes: a secondary radiator 5 communicated with the primary radiator 4 through a coolant circulation pipeline; the coolant circulation pipeline includes a liquid inlet pipeline 6 and a liquid outlet pipeline 7; the pump 8 installed on the liquid outlet pipeline 7; the cooling liquid flowing out from the primary radiator 4 enters the secondary radiator 5 through the liquid outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com