Fe-Ga base magnetism driven elastic silk and part using this material

A technology of magnetostriction and magnetostriction coefficient, which is applied in the selection of materials for magnetostrictive devices, the magnetic properties of inorganic materials, and the selection of device materials, which can solve the problems of not finding Fe-Ga magnetostrictive wire patents, Achieve good magnetostrictive inverse effect, improve sensitivity and precision, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

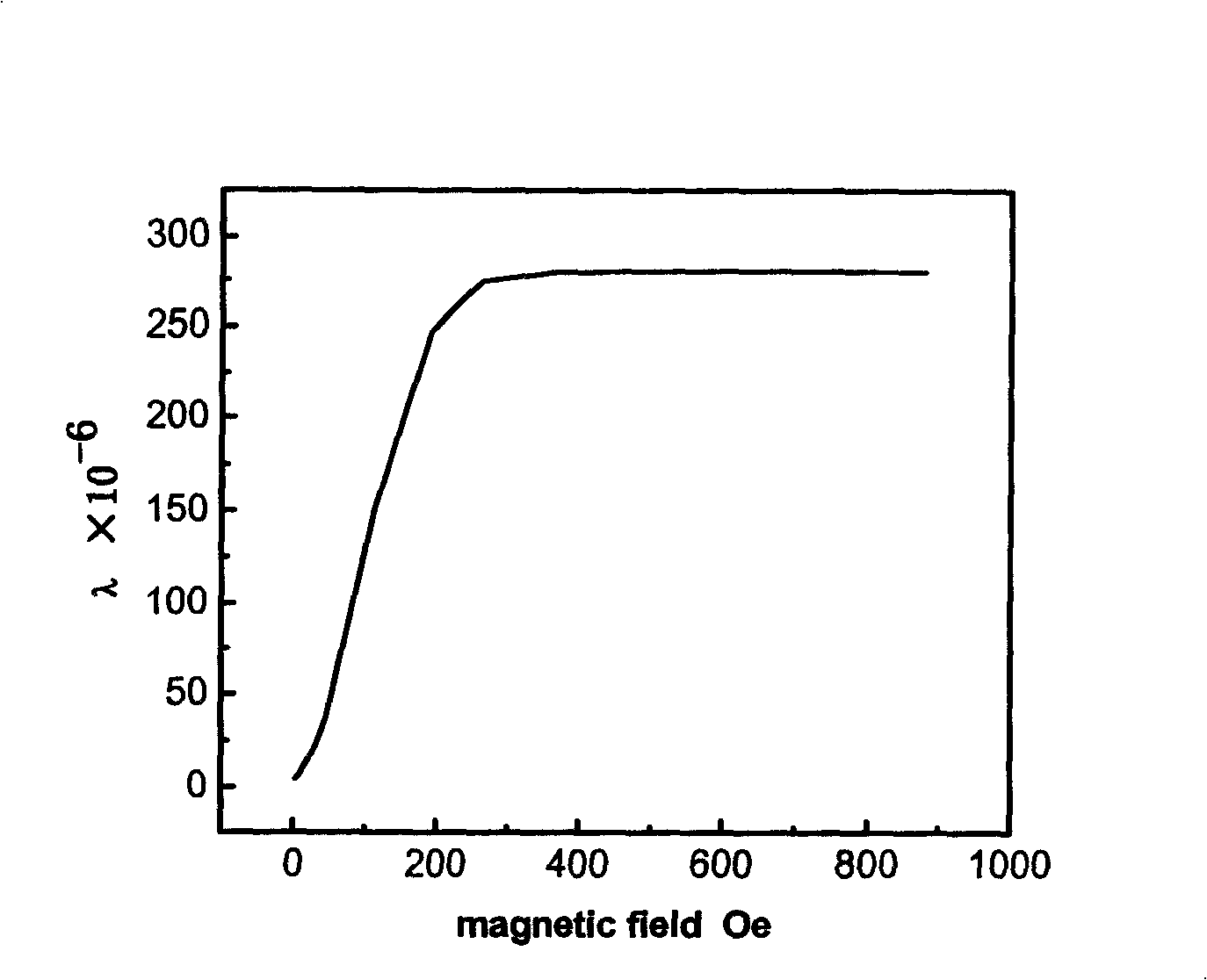

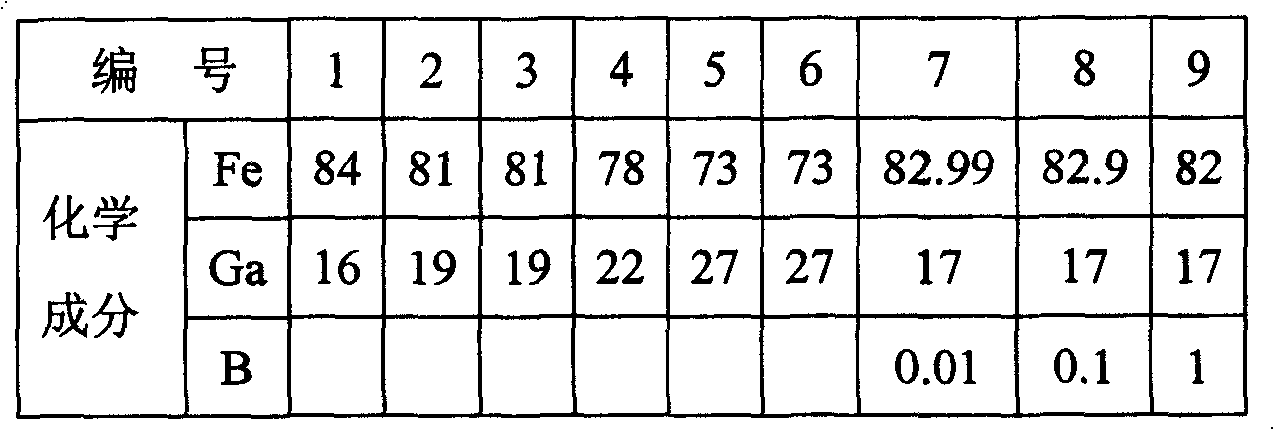

[0024] The chemical composition of the prepared Fe-Ga-based magnetostrictive yarn is expressed in atomic percentage, see Tables 1-4; the dimensions and magnetostrictive properties are shown in Tables 5-8.

[0025] Table 1

[0026]

[0027] Table 2

[0028]

[0029]

[0030] table 3

[0031]

[0032] Table 4

[0033]

[0034] table 5

[0035]

[0036] Table 6

[0037]

[0038] Table 7

[0039]

[0040] Table 8

[0041]

[0042] Table 9

[0043]

[0044] Table 10

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com