Nickel-base superalloy, unidirectional-solidification process therefor, and castings formed therefrom

a technology of superalloy and nickel-base, which is applied in the field of nickel-base superalloy compositions, can solve the problems of inability to accept off-axial grains and reduce fatigue life, and achieve the effect of reducing the incidence of freckling and superior results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

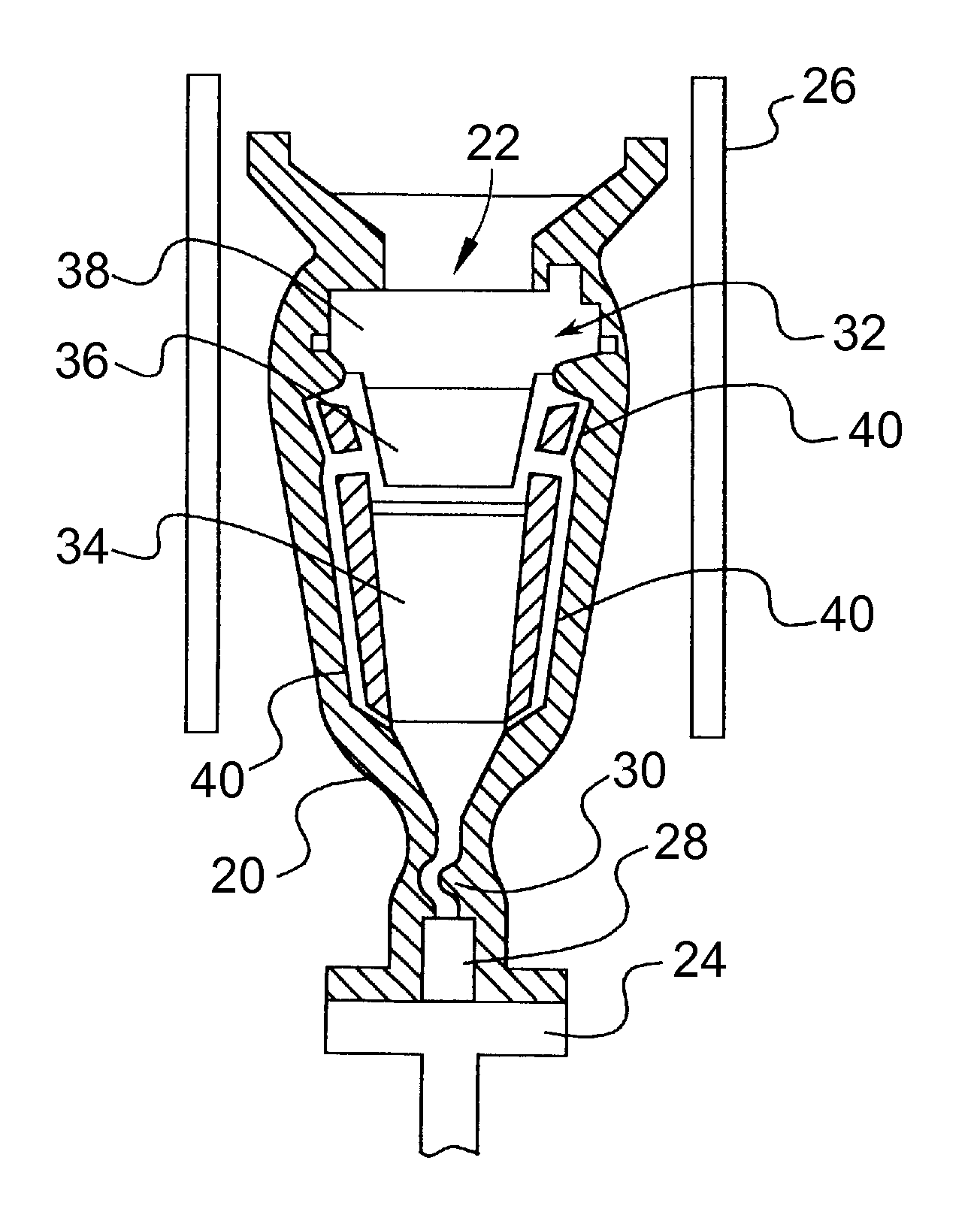

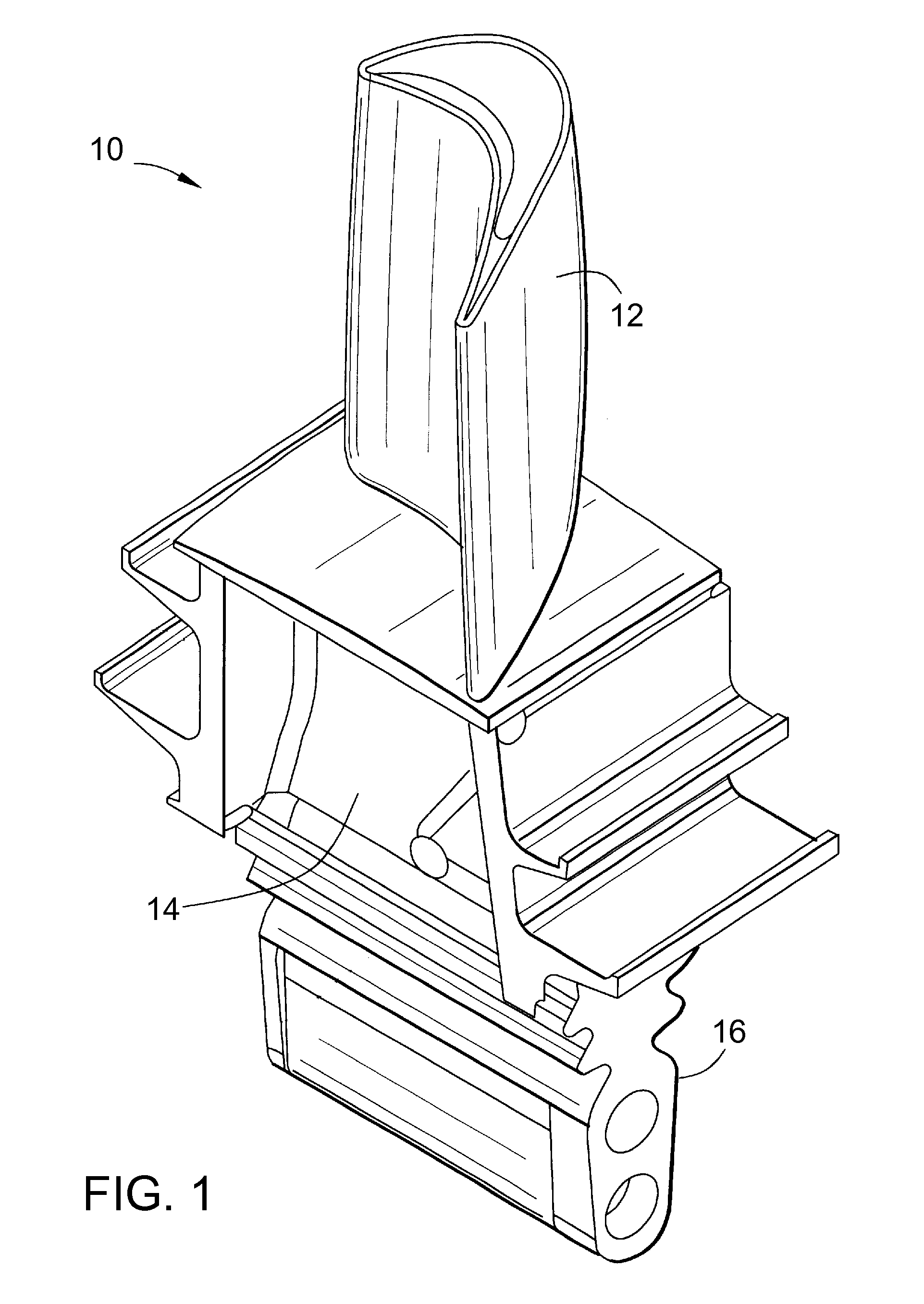

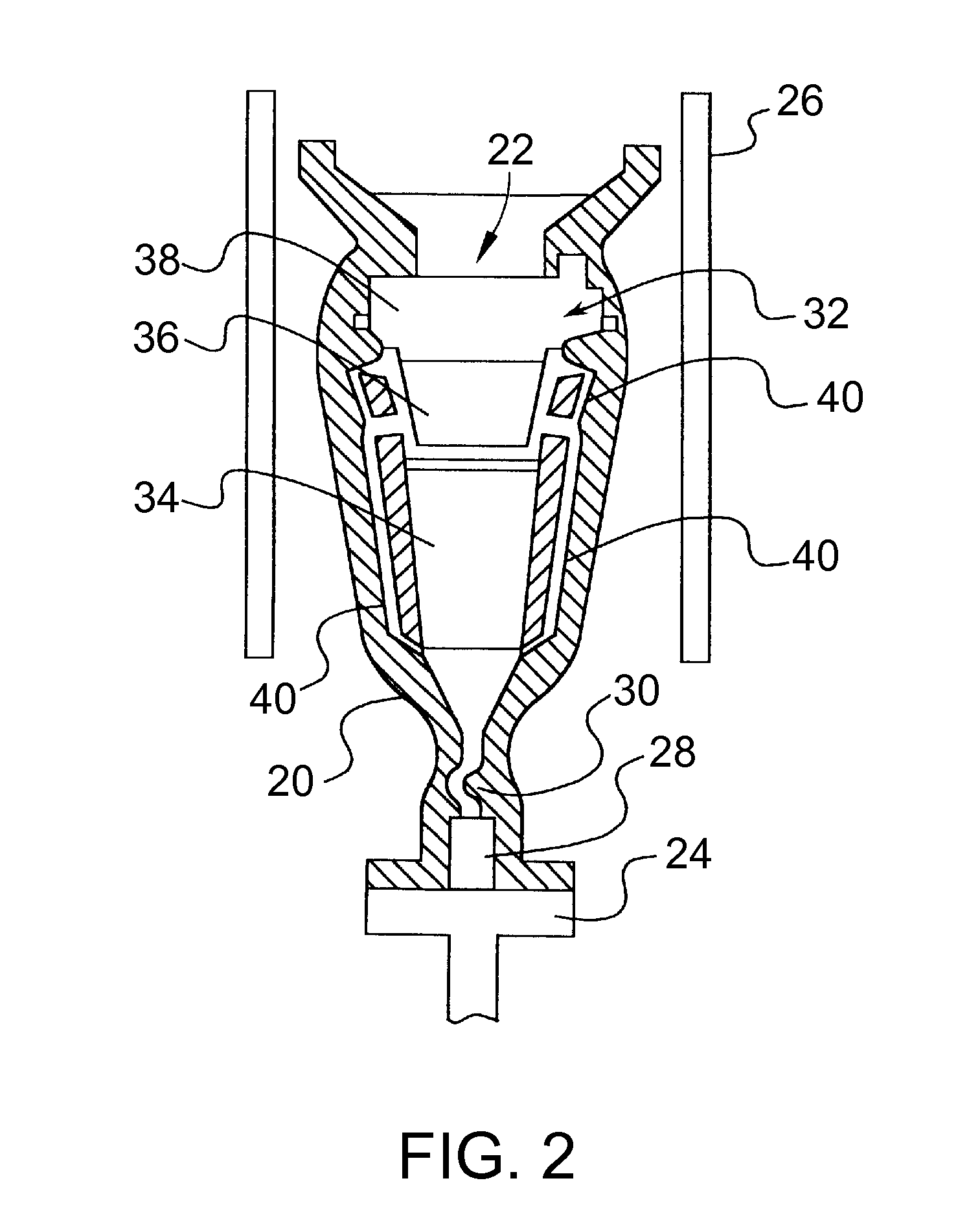

[0015]The present invention was the result of an effort to develop a nickel-base alloy having properties similar to the nickel-base alloy commercially known as René N5, but with a chemistry that reduces the tendency for freckling while maintaining the mechanical properties of the alloy, such as high temperature strength (including creep resistance), oxidation resistance, fatigue resistance, castability, and microstructural stability for use in such applications as the hot gas flow path of a gas turbine. As an example, FIG. 1 depicts a first stage bucket 10 for a land-based gas turbine, such as the H and FB class gas turbines used in the power-generating industry and manufactured by the assignee of the invention. The bucket 10 has an airfoil 12 and shank 14, with a dovetail 16 formed on the shank 14 for anchoring the bucket 10 to a turbine disk (not shown). As is common with turbine buckets, the bucket 10 is preferably unidirectionally cast to have a columnar single crystal (SX) or c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com