Method for modifying single crystal copper with graphene

A graphene-modified, single-crystal copper technology, applied in the field of single-crystal copper, to achieve the effects of excellent strength, electrical and thermal conductivity, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

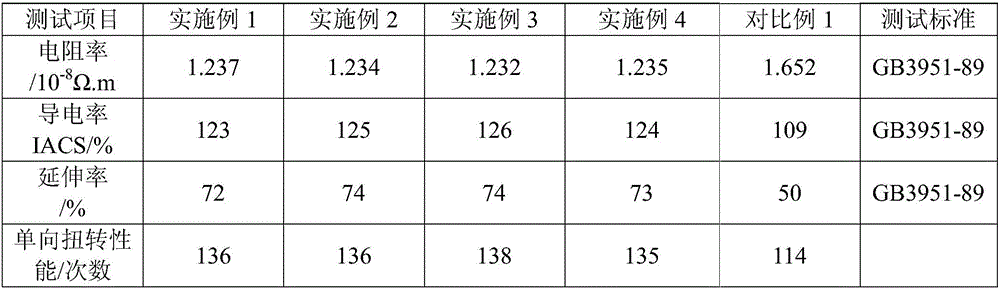

Examples

Embodiment 1

[0025] Embodiment 1: the method for the graphene modified single crystal copper of the present embodiment, comprises the following steps:

[0026] Under a protective atmosphere, put blister copper in a crucible and heat it to 1200°C to melt to obtain copper liquid;

[0027] The copper liquid is introduced into the casting mold, heated to 1070°C, adding graphene powder accounting for 0.1wt% of the mass of the copper liquid, stirring evenly, cooling the copper liquid at the outlet of the casting mold, and the cooling distance is 12cm, so that the copper The liquid is solidified in one direction along the exit direction of the mold, and is continuously pulled and casted at a speed of 26mm / min to obtain copper ingots, which are heat-treated and cold-drawn to obtain graphene-modified single-crystal copper wires.

Embodiment 2

[0028] Embodiment 2: the method for the graphene modified single crystal copper of the present embodiment, comprises the following steps:

[0029] Under the protection of argon, place the blister copper in a crucible and heat it to 1250°C to melt to obtain copper liquid;

[0030] The copper liquid is introduced into the mold, heated to 1100°C, adding graphene powder accounting for 0.5wt% of the mass of the copper liquid, and stirred evenly, and the copper liquid is cooled at the outlet of the mold according to the cooling water volume of 800mL / min. The cooling distance 18cm, make described copper liquid realize unidirectional solidification along mold outlet direction, and continuous traction continuous casting, the static pressure head of copper liquid is 16mm, and continuous casting speed is 25mm / min, obtains copper ingot, and copper ingot passes through After heat treatment and cold drawing, a graphene-modified single crystal copper wire is prepared.

Embodiment 3

[0031] Embodiment 3: the method for the graphene modified single crystal copper of the present embodiment, comprises the following steps:

[0032] Under the protection of nitrogen, place the blister copper in a graphite crucible and heat it to 1300°C to melt to obtain copper liquid;

[0033] The copper liquid is introduced into the casting mold, heated to 1100°C, adding graphene powder accounting for 0.6wt% of the mass of the copper liquid, stirring evenly, and cooling the copper liquid at the outlet of the casting mold according to the cooling water volume of 100mL / min. The cooling distance It is 16cm, makes described copper liquid realize unidirectional solidification along the mold exit direction, and continuous traction continuous casting, the static pressure head of copper liquid is 15mm, and continuous casting speed is 24mm / min, obtains copper ingot, and copper ingot passes through After heat treatment and cold drawing, a graphene-modified single crystal copper wire is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com