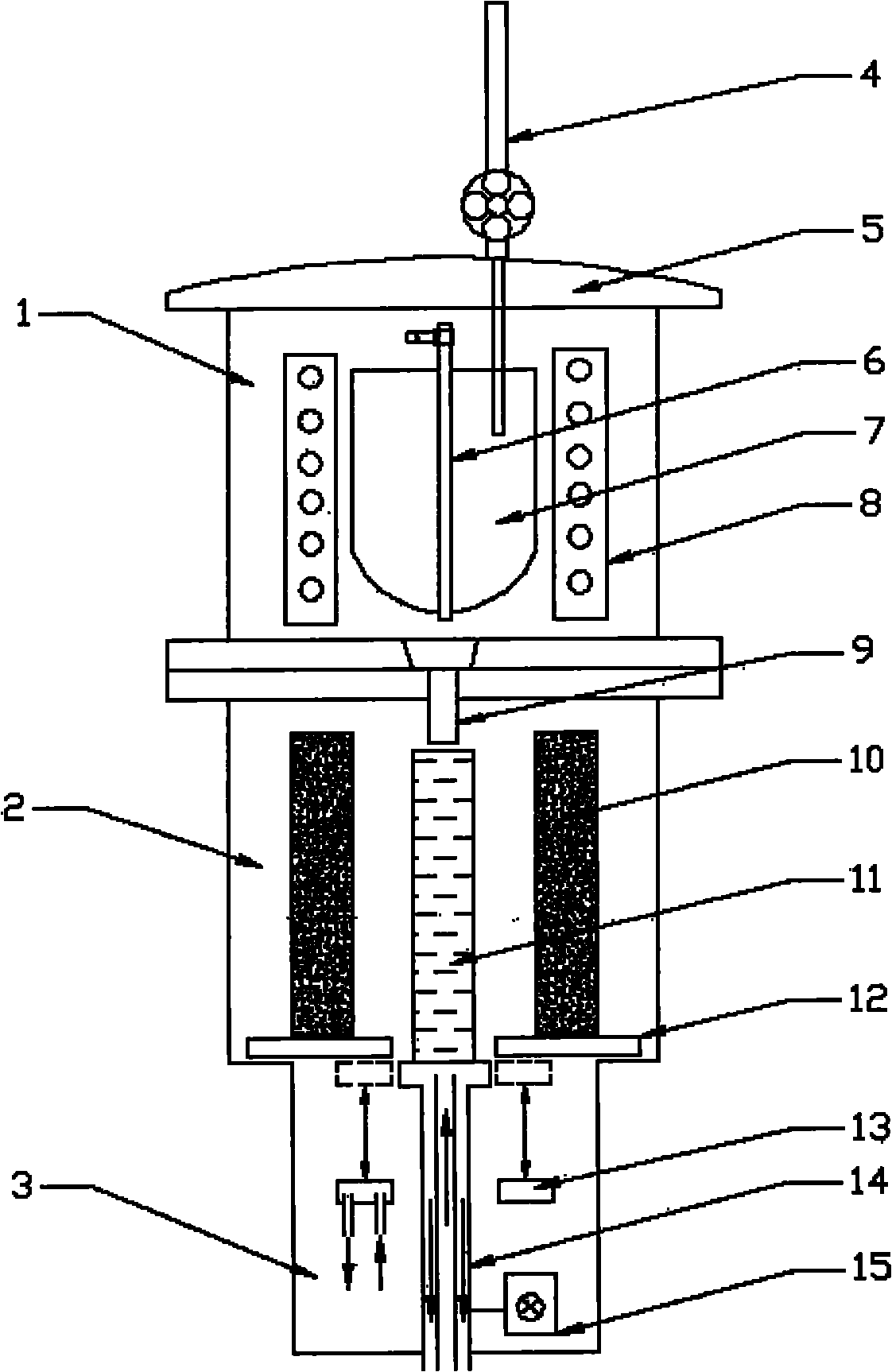

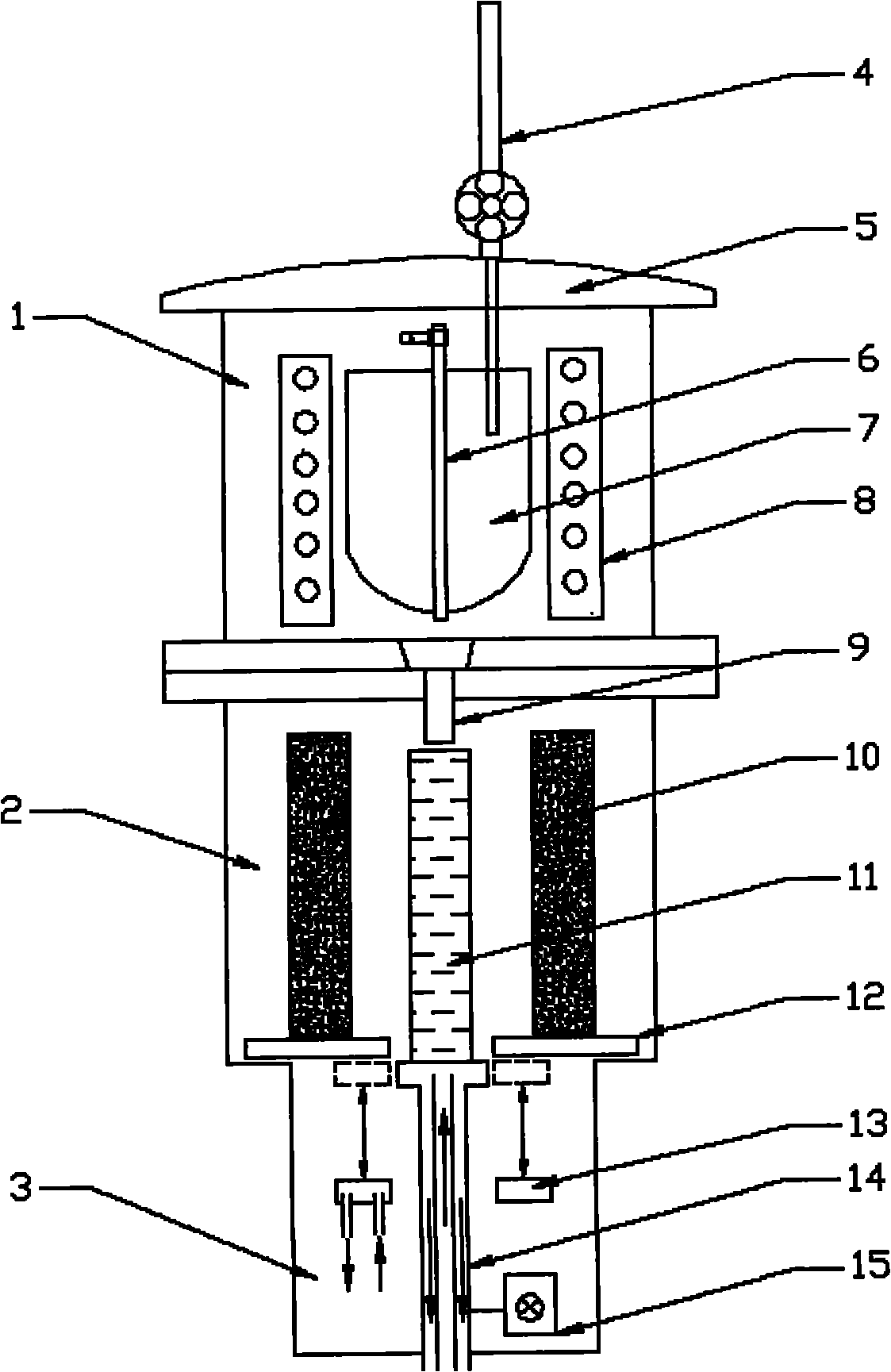

Controllable temperature gradient unidirectional solidification device and method

A technology of directional solidification and temperature gradient, applied in the field of preparing materials with magnetic anisotropy and tissue anisotropy, can solve the problem of poor consistency of material structure and performance, inability to realize temperature gradient control of solid-liquid interface, low yield, etc. problems, to achieve the effect of good consistency, high yield and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Insert the pouring plug rod 6 into the pouring hole at the bottom of the smelting crucible 7, and then pour the purity not lower than 99.5% Tb, 99.5Dy and high-purity Fe into Tb 0.3 Dy 0.7 Fe 2 (Atomic ratio) 11.26 kg was put into the melting crucible 7 . Start the vacuum system to raise the vacuum to 10 -3 Pa, filled with 0.5atm argon. Start the power supply to heat and melt the raw materials. When the raw materials are completely melted, shake the handwheel of the temperature measuring mechanism to make the temperature measuring rod contact the molten metal for temperature measurement, and adjust the power of the induction power supply to make the melting temperature reach 1300°C. Adjust the movable water-cooling ring 13 to a distance of 10mm from the lower end of the solid-liquid interface during directional solidification, so that the temperature gradient of the solid-liquid interface during the directional solidification process is 500°C / cm. Start the control m...

Embodiment 2

[0022] Insert the pouring plug rod 6 into the pouring hole at the bottom of the smelting crucible 7, and then pour the purity not lower than 99.5% Tb, 99.5Dy and high-purity Fe into Tb 0.3 Dy 0.7 Fe 2 (Atomic ratio) 13.12 kg was put into the melting crucible 7 . Start the vacuum system to raise the vacuum to 10 -3 Pa, filled with 0.5atm argon. Start the power supply to heat and melt the raw materials. When the raw materials are completely melted, shake the handwheel of the temperature measuring mechanism to make the temperature measuring rod contact the molten metal for temperature measurement, and adjust the power of the induction power supply to make the melting temperature reach 1300°C. Adjust the movable water-cooling ring 13 to a distance of 200 mm from the lower end of the solid-liquid interface during directional solidification, so that the temperature gradient of the solid-liquid interface during the directional solidification process is 5° C. / cm. Start the control...

Embodiment 3

[0024] Insert the pouring plug rod 6 into the pouring hole at the bottom of the smelting crucible 7, and then pour the purity not lower than 99.5% Tb, 99.5Dy and high-purity Fe into Tb 0.3 Dy 0.7 Fe 2 (Atomic ratio) 14.61 kg was put into the melting crucible 7 . Start the vacuum system to raise the vacuum to 10 -3 Pa, filled with 0.5atm argon. Start the power supply to heat and melt the raw materials. When the raw materials are completely melted, shake the handwheel of the temperature measuring mechanism to make the temperature measuring rod contact the molten metal for temperature measurement, and adjust the power of the induction power supply to make the melting temperature reach 1300°C. Adjust the movable water cooling ring 13 to a distance of 110mm from the lower end of the solid-liquid interface during directional solidification, so that the temperature gradient of the solid-liquid interface during the directional solidification process is 239.50°C / cm. Start the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com