Vertical ceramic mould housing for single crystal blade forming and forming method of ceramic mould housing

A technology of ceramic mold shells and single crystal blades, which is applied in casting molding equipment, molds, cores, etc., can solve the problems of low qualification rate, affecting radiation heat transfer, time-consuming molding process, etc., to prevent fracture and melt. The effect of leakage, simple support structure and convenient molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

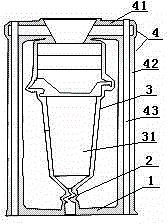

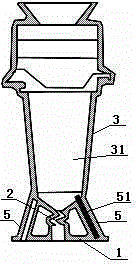

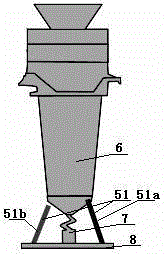

[0023] see figure 2 The invention relates to a vertical ceramic formwork for single crystal blade molding, wherein the blade is mainly a large blade for a heavy-duty gas turbine. The ceramic formwork 3 has a blade cavity 31 corresponding to the design blade shape, and the ceramic formwork 3 is erected above the chassis 1, and a crystal selector 2 is arranged between the chassis 1 and the bottom of the ceramic formwork 3, and they all It is integrally formed. A plurality of supporting columns 5 (usually three to six, such as four; can be solid supporting columns, or hollow supporting columns, can also be solid and hollow) between the bottom of the aforementioned chassis 1 and the ceramic formwork 3. Mixed support columns), these support columns 5 are evenly arranged around the periphery of the crystal selector 2, and each support column 5 is formed in a way that the upper end is inclined to the center (referring to the vertical axis of the ceramic mold shell 3), and each supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com