Silicon purification method

A purification method, silicon crystallization technology, applied in the direction of self-solidification, silicon compounds, chemical instruments and methods, etc., can solve undisclosed problems, and achieve low cost, low energy consumption, and accurate device effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] In order to implement the present invention, various experiments were conducted on the composition of the aluminum-silicon melt and the temperature at which the melt was maintained. These research results show that it is better to make the composition of the melt 66% aluminum - 34% silicon (weight %, the same below), and keep the temperature of the melt from 890°C to 920°C for casting. If this casting can be continuously added while melting The charged silicon side is cast, and impurities in the crystallized silicon ingot 3 are further purified. In addition, when titanium is added with an upper limit of 0.3% to the aluminum-silicon melt of the above composition, and silicon is crystallized from the aluminum-silicon-titanium melt, boron in the crystallized silicon ingot 3 decreases particularly well. . Embodiments of the present invention will be specifically described below.

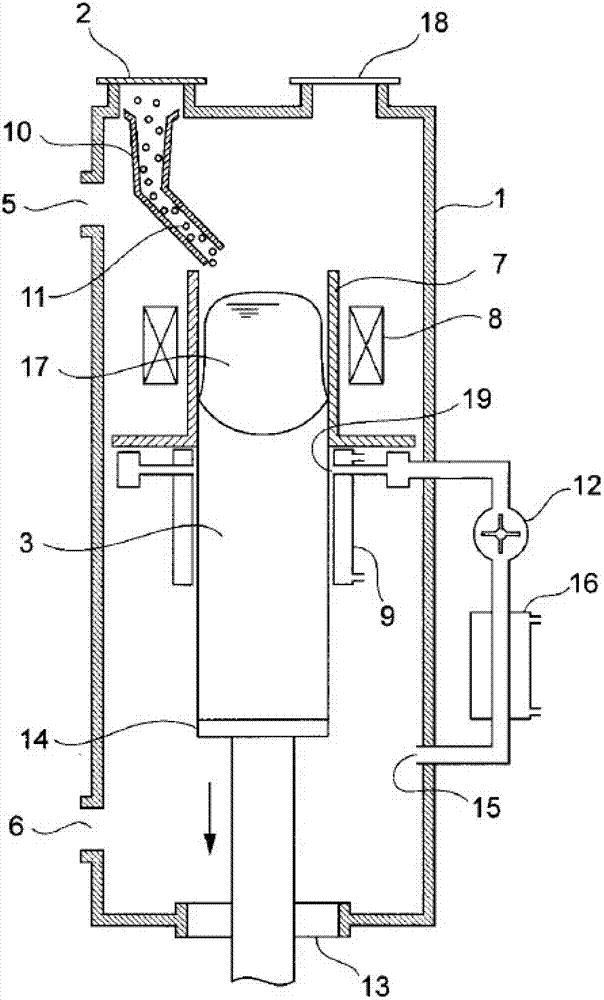

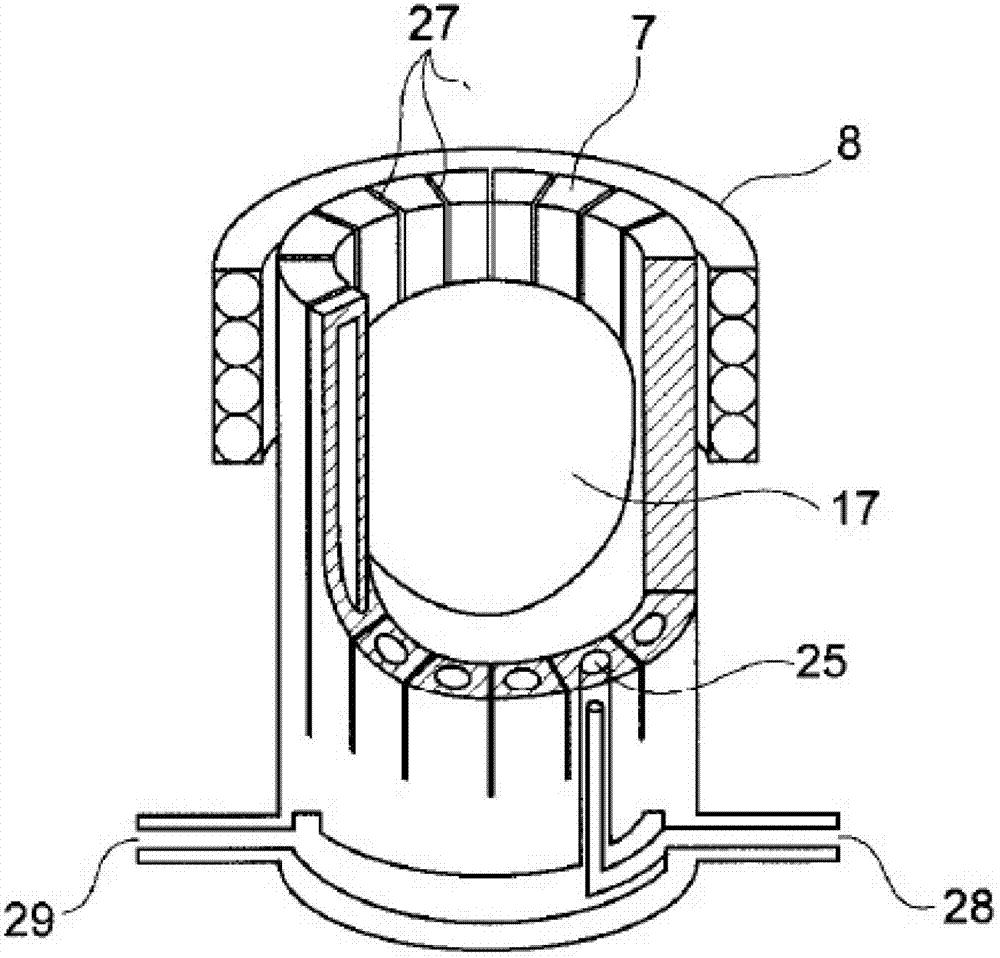

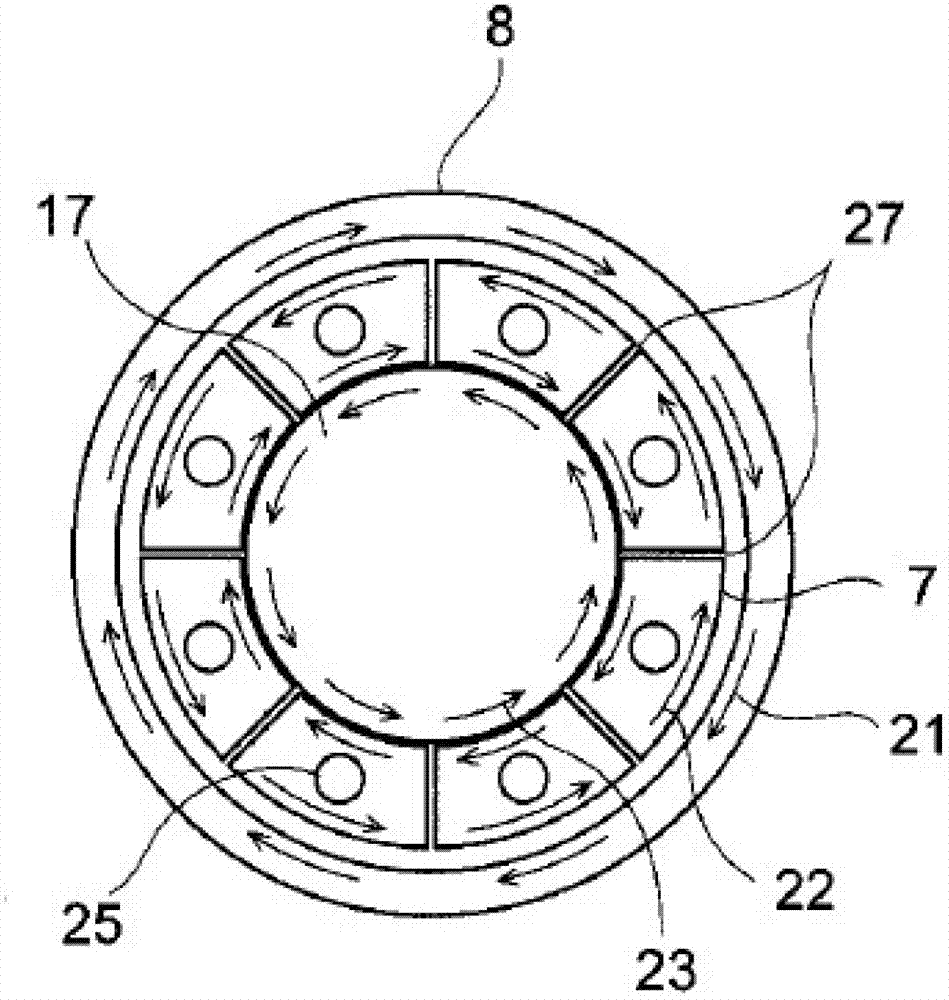

[0053] device structure with figure 1 Shown applies. That is to say, the cooling crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com