Casting method and apparatus

a casting method and apparatus technology, applied in the field of casting technologies, can solve the problems of reducing the yield of products, dendritic growth tending to break down, and misoriented grains are likely to form, and achieve the effect of eliminating the formation of macrosegregation defects such as freckles and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

A. Specific Example 1

Macrosegregation in Unidirectional Solidification of Ni-10 wt % Al Round Ingot

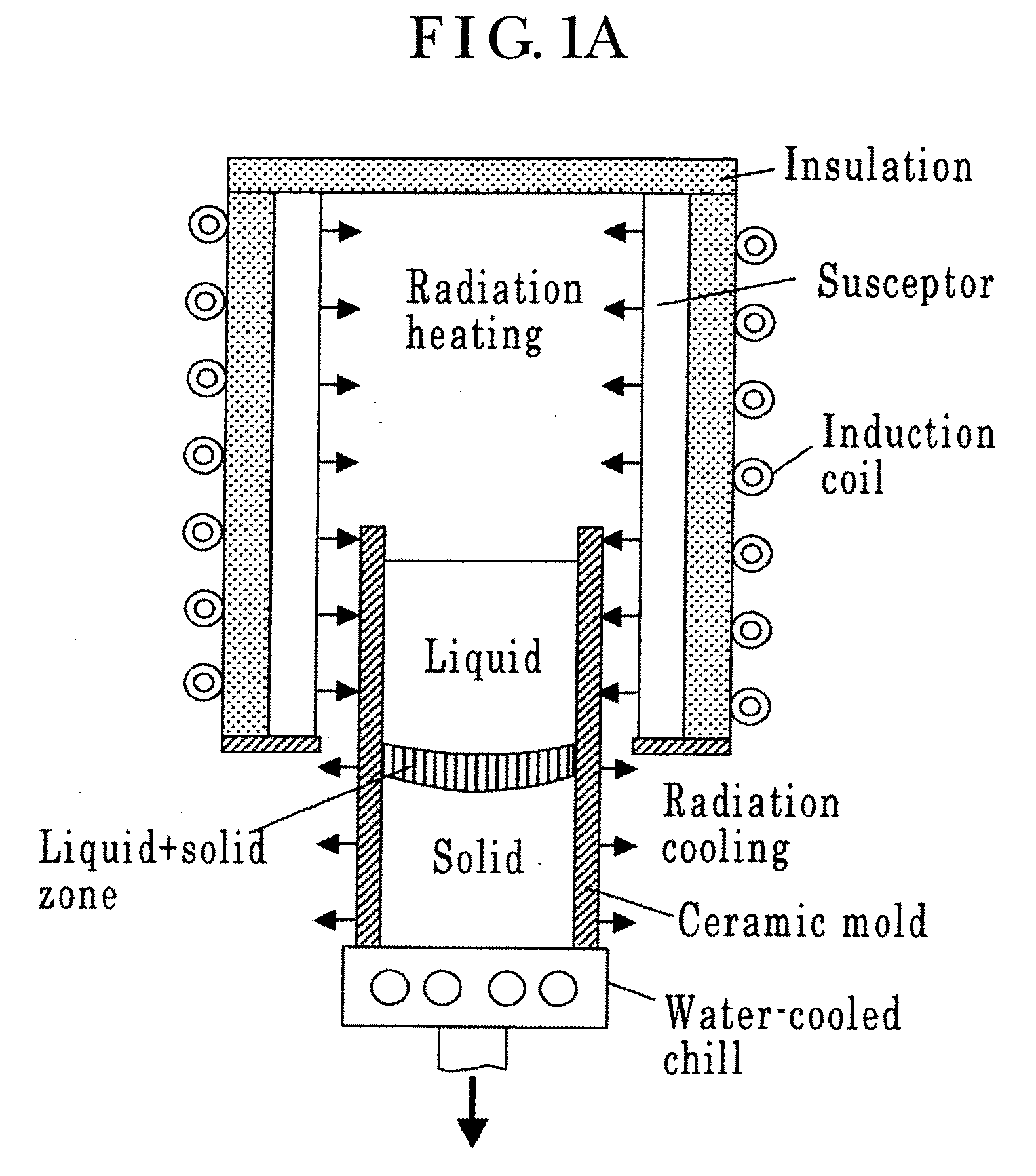

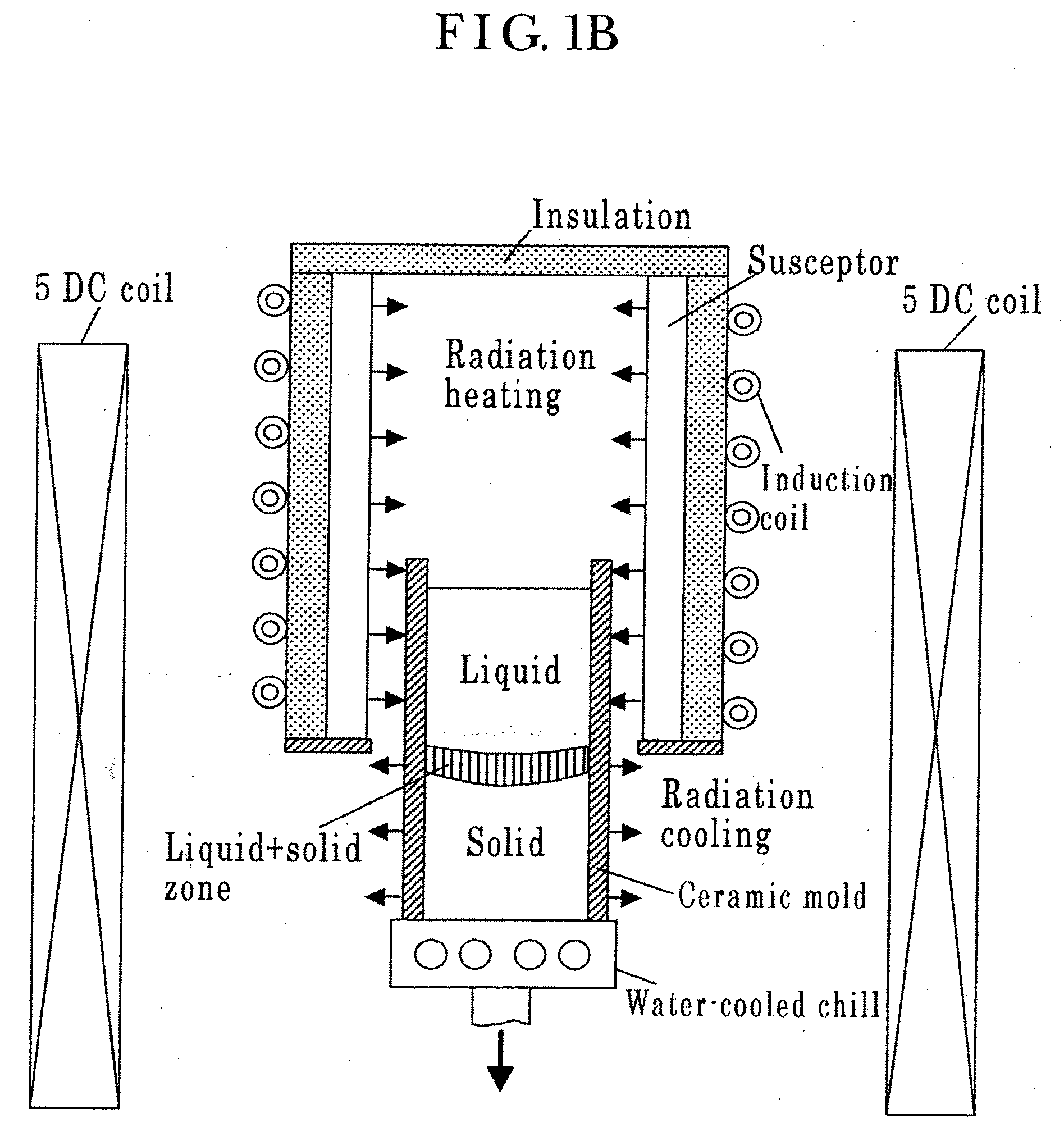

[0089]Schematic diagram of a conventional unidirectional solidification apparatus is shown in FIG. 1(A). Susceptor is heated by induction coil and the ceramic mold is then radiation-heated by the susceptor. The bottom of the ceramic mold is cooled by water-cooled chill, and the mold is withdrawn gradually downward to establish unidirectional solidification (instead, it is also possible to rise the heating furnace while the mold is fixed). Giamei and Kear have shown that the channel segregation generally termed ‘freckles’ appears at O.D. of unidirectionally solidified Ni-base superalloy monocrystal round ingots of the type upward buoyancy (refer to FIGS. 1 to 4 of Ref. (6)), and clarified the size effect that more freckles form as the diameters of the ingots increase (refer to Table II of the same reference). They have also shown that the freckles take place at O.D. of unidirectionally ...

example 2

B. Specific Example 2

Macrosegregation of Unidirectionally Solidified Ni-10 wt % Al Square Ingot

[0096]In order to investigate the influences of magnetic field directions on the formation of freckles, calculations were done for square ingots. The dimensions of cross section were determined to have the equivalent cross-sectional area to that of the Specific Example 1, i.e., 60 mm square. All other casting parameters are the same as those of round ingot (refer to Table 2). Computations were performed for ¼ cross-sections considering the symmetricity. The number of elements for the ingot is 23004 (18 in X dir.×18 in Y dir.×71 in Z dir.).

[0097]The macrosegregations of the conventional ingot with no magnetic field are shown in FIGS. 9 to 11. As shown in FIGS. 9(A) and 9(B), the freckles take place in vertical sections at outsides with roughly equal intervals. The maximum value of C / Co is about 1.18. FIGS. 10(A) and 10(B) show the states of macrosegregation being formed after 20 minutes dur...

example 4

D. Specific Example 4

Macrosegregation of Remelting-Processed IN718 Ni-Base

[0108]Superalloy Ingot

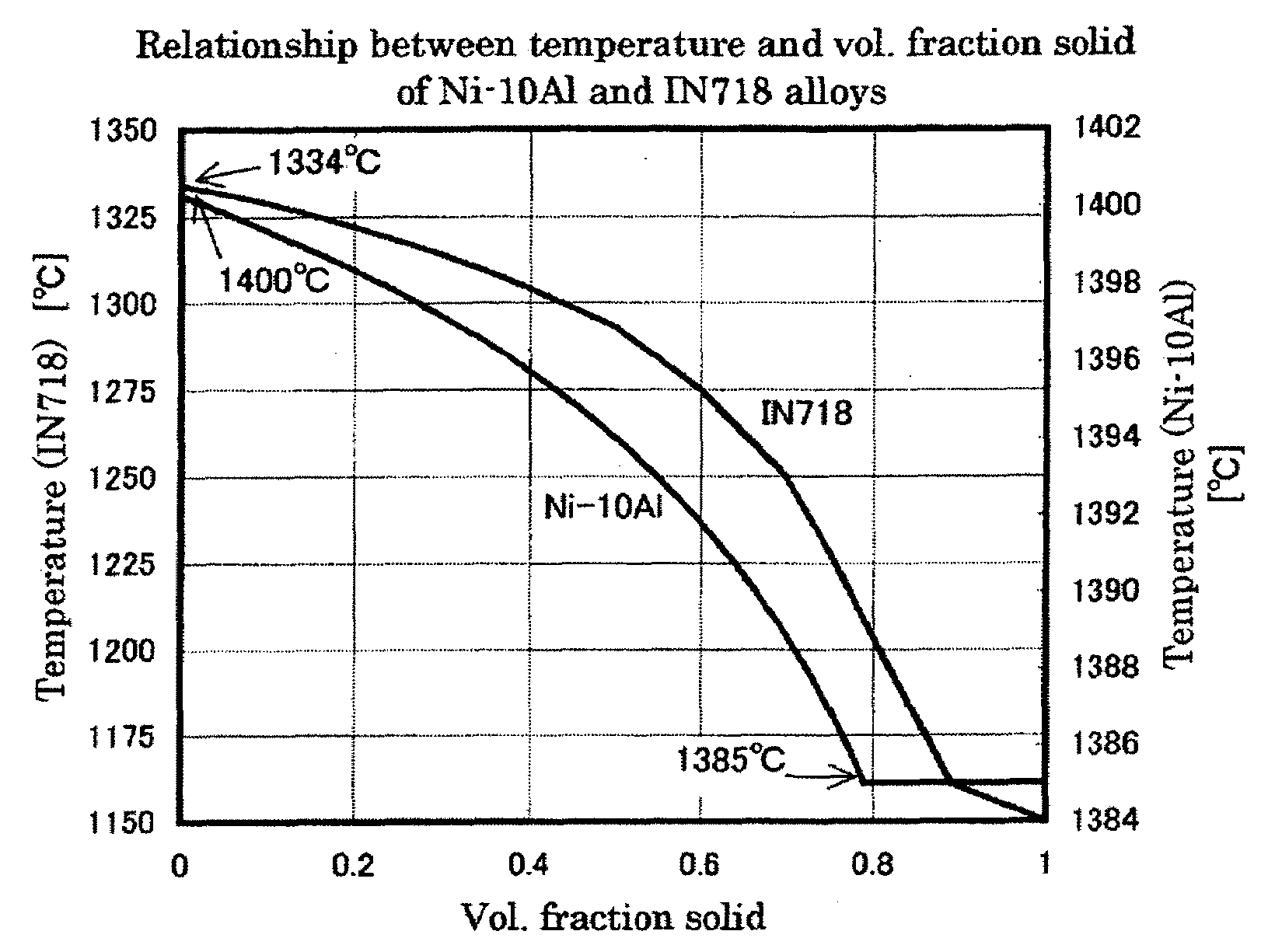

[0109]The chemical compositions and physical properties used for computations are given in Table 3. The chemical compositions and the relationships between temperature vs. liquidus compositions and temperature vs. solidus compositions respectively in the multi-component system of IN718 were reproduced from FIGS. 1 to 3 of Ref. (10). Hence, the computational results of the relationship between temperature and vol. fraction solid (refer to FIG. 2), and the variations of solute concentrations in liquid phase during solidification (refer to FIG. 4) are the same as those of Ref. (10). Also, the variation of the liquid density by Eq. (8) is shown in FIG. 5, indicating that the alloy is of downward type of buoyancy.

[0110]Van Den Avyle, et al. reported in the aforementioned Ref. (2) that freckles formed in the middle of radial direction and ‘central’ freckles formed at the center in remelting-pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| static magnetic field | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| static magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com