Method for recovering silicon carbide, high-purity silicon and dispersion liquid from silicon material linear cutting waste mortar

A technology of silicon carbide and wire cutting, applied in the field of high-purity silicon and dispersion liquid, and recovery of silicon carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

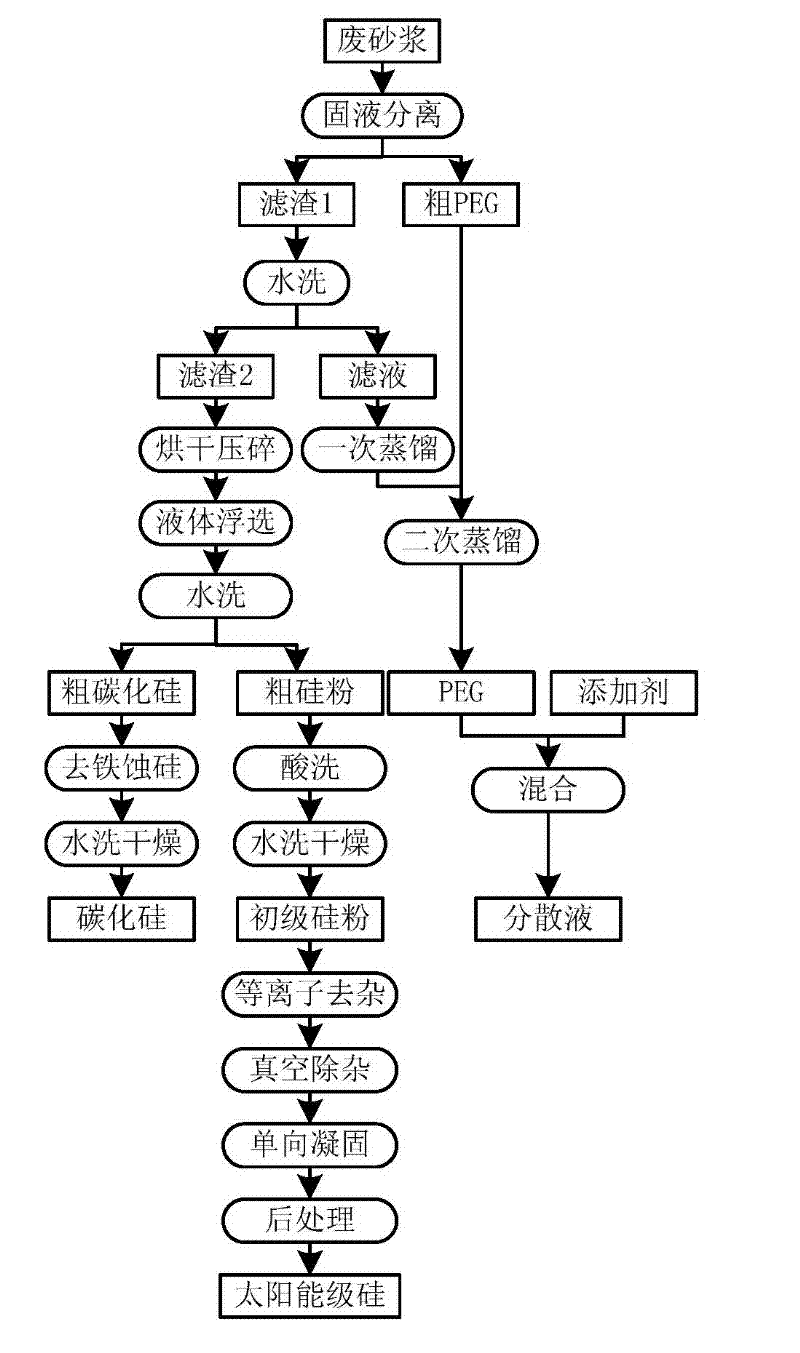

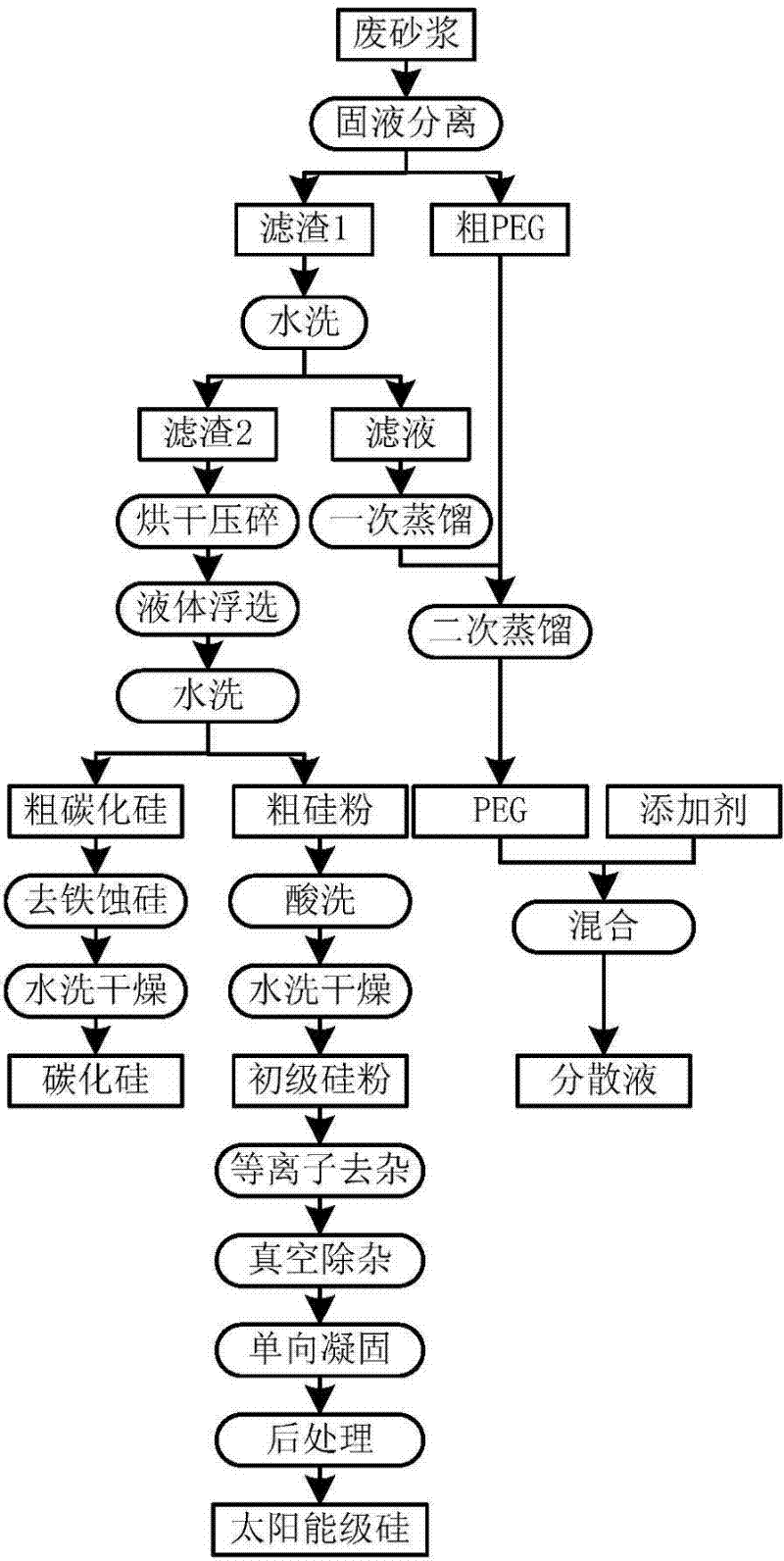

[0064] Cooperate figure 1 As shown, the production process is as follows: take 500Kg of waste mortar, first centrifuge it with a centrifuge, and separate the solid and liquid to obtain 340Kg of solid filter residue 1 and 156Kg of crude PEG, add 150Kg of deionized water to the filter residue 1, and stir well After centrifugal filtration, 162Kg of secondary filtrate and 326Kg of secondary filter residue were obtained.

[0065] The secondary filtrate was distilled under reduced pressure at a vacuum of 80 Torr and a temperature of 80°C to finally obtain 45Kg of a liquid with a water content of 6.6% wt. The 156Kg crude PEG of the primary filtrate was combined to a total of 201Kg, and the secondary distillation was carried out at a vacuum of 50 Torr and a temperature of 70°C , obtain PEG185Kg with water content<0.5%wt, add polyacrylic acid sulfonate, aerosol silicon dioxide additive and obtain viscosity 65mPaS, pH value 5.8, the recovery dispersion liquid 188Kg of water content 0.25...

Embodiment 2

[0071] Cooperate figure 1 As shown, the production process is as follows: take 500Kg of waste mortar, first centrifuge it with a centrifuge, and separate the solid and liquid to obtain 340Kg of solid filter residue 1 and 156Kg of crude PEG, add 150Kg of deionized water to the filter residue 1, and stir well After centrifugal filtration, 162Kg of secondary filtrate and 326Kg of secondary filter residue were obtained.

[0072] The secondary filtrate was distilled under reduced pressure at a vacuum degree of 80 Torr and a temperature of 80°C to obtain 46Kg of a liquid with a water content of 7%wt. The 156Kg crude PEG of the primary filtrate was combined to a total of 202Kg, and the secondary distillation was carried out at a vacuum degree of 50 Torr and a temperature of 70°C 184Kg of PEG with a water content of <0.5%wt was obtained, and after adding organic phosphonate, alkyl sulfonate polyacrylic acid sulfonate, and hydroxycellulose additives, 189Kg of a recovered dispersion wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com