Cemented carbide blank suitable for electric discharge machining and cemented carbide body made by electric discharge machining

a technology of electric discharge machining and cemented carbide, which is applied in the direction of coatings, metallic material coating processes, etc., can solve the problems of edm finished cemented carbide body cracking, and edm finished cemented carbide body reducing the strength of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

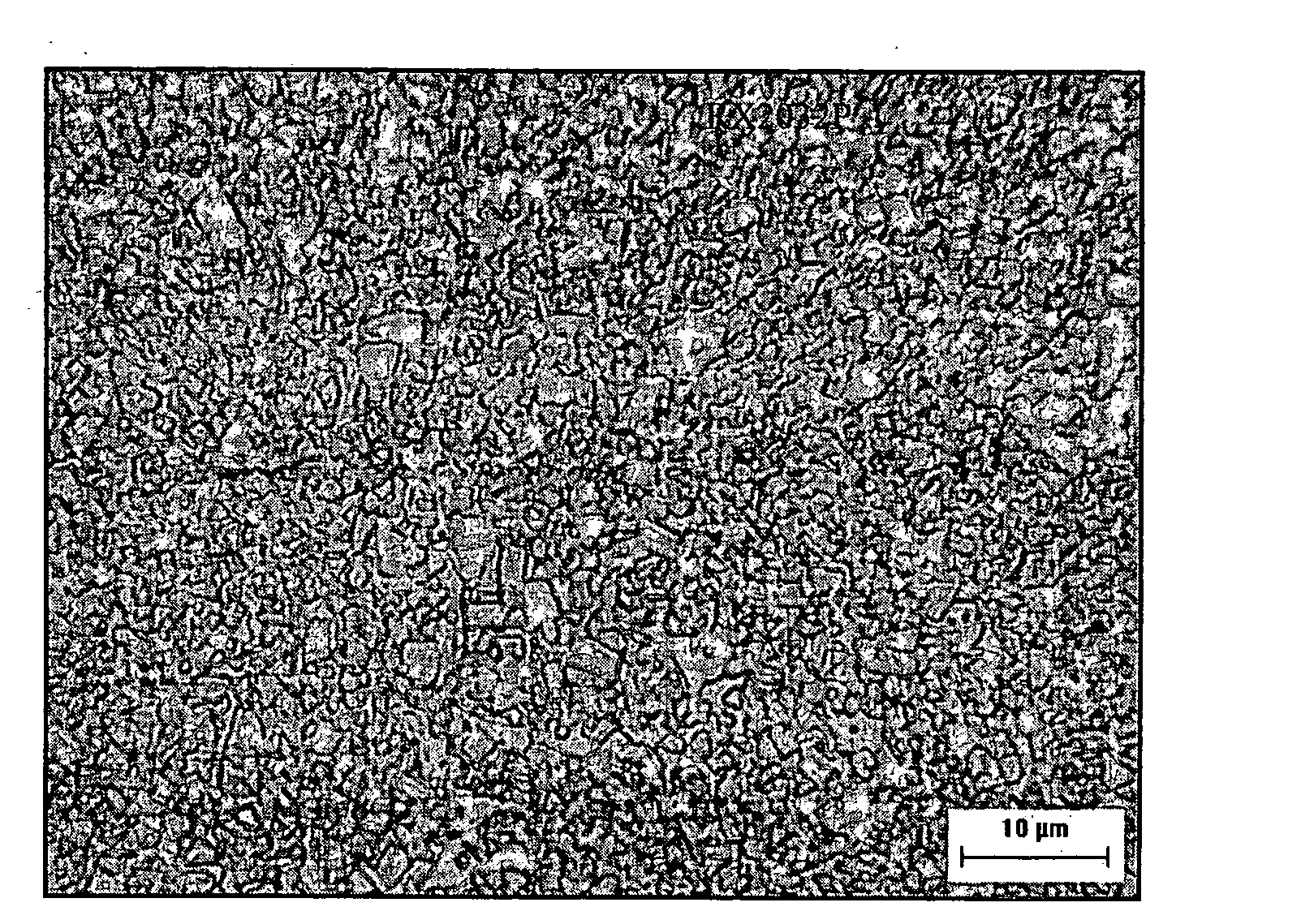

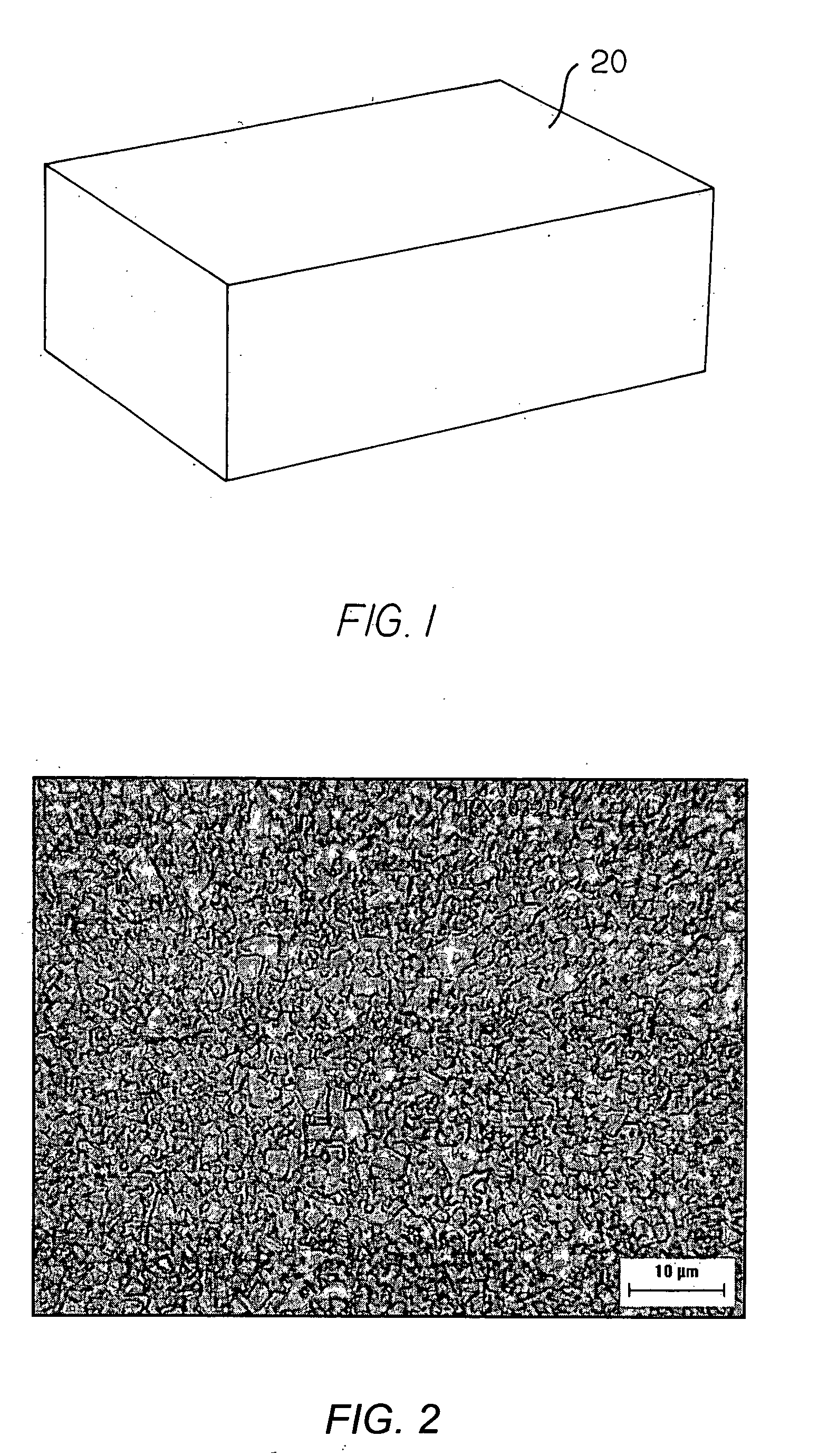

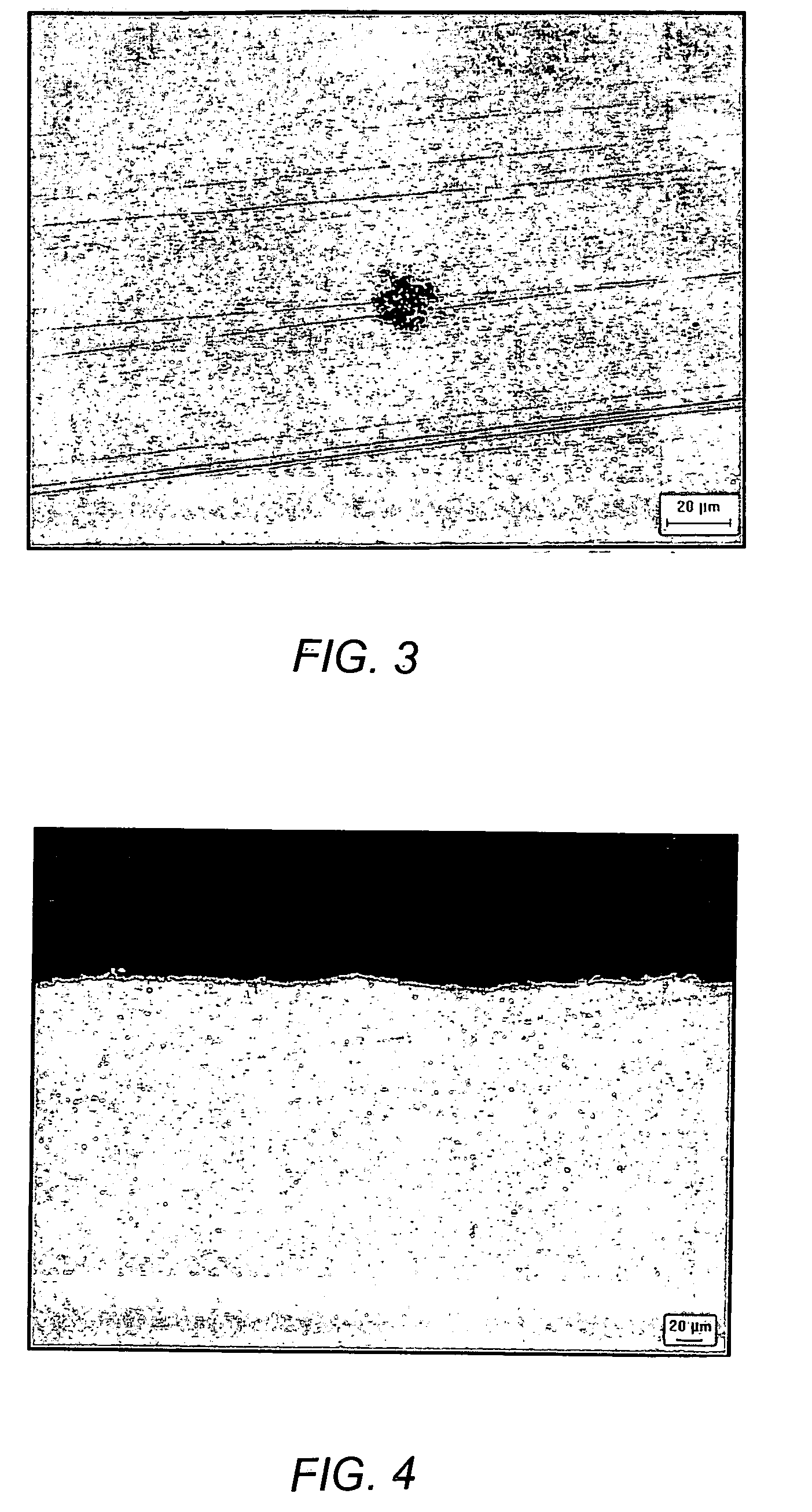

Image

Examples

example 2

[0058] Example 2 is another specific embodiment of the invention. made using the following starting powder mixture: about 91.2 weight percent tungsten carbide (the particle size of the tungsten carbide is about 0.4 to about 0.6 micrometers (μm)), about 8.0 weight percent cobalt, about 0.5 weight percent chromium carbide (Cr3C2), about 0.1 weight percent vanadium carbide, about 0.5 weight percent tungsten, and about 0.2 weight percent molybdenum. This powder mixture was attritor milled in heptane using cemented carbide balls for about 6 hours.

[0059] The powder mixture was then pressed into a green compact. The green compact was de-waxed at a temperature between about 400 degrees Centigrade and about 650 degrees Centigrade. The de-waxed compact was then sintered at 1405 degrees Centigrade for 60 minutes in a vacuum followed by hot isostatic pressing at a temperature of about 1405 degrees Centigrade and a pressure equal to about 450 pounds per square inch (3.1 MPa) in argon gas for a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com