Hard alloy, hard alloy cutter bar and manufacturing method thereof

A technology of cemented carbide and its manufacturing method, which is applied in the field of alloys, can solve problems such as excessive oxygen content in powder materials and affect product quality, and achieve the effects of improving red hardness, inhibiting grain growth, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

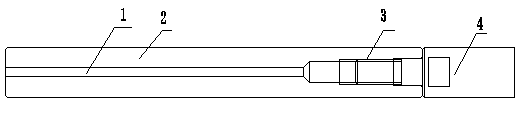

Image

Examples

Embodiment 1

[0029] Embodiment 1: The cemented carbide of this embodiment contains at least 80 parts by mass of tungsten carbide, 20 parts by mass of cobalt, 0.15 parts by mass of tantalum carbide, 0.4 parts by mass of chromium carbide, and 0.1 part by mass of vanadium carbide. The tungsten carbide is a tungsten carbide powder with a particle size of 1.0-1.2 μm, a total carbon content of 6.0%, and an oxygen content of 0.15%. The cemented carbide manufacturing method of the present embodiment comprises the following steps: putting 80 parts by mass of tungsten carbide, 20 parts by mass of cobalt, 0.15 parts by mass of tantalum carbide, 0.4 parts by mass of chromium carbide, and 0.1 part by mass of vanadium carbide into a ball mill, adding tungsten carbide , cobalt, tantalum carbide, chromium carbide and vanadium carbide total mass of 0.25 parts by mass of alcohol and 0.015wt% oleic acid were mixed and milled for 24 hours, unloaded, dried, and sieved; The forming agent is composed of 2.5 part...

Embodiment 2

[0030]Embodiment 2: The cemented carbide of this embodiment contains at least 90 parts by mass of tungsten carbide, 10 parts by mass of cobalt, 0.5 parts by mass of tantalum carbide, 0.2 parts by mass of chromium carbide, and 0.3 parts by mass of vanadium carbide. The tungsten carbide is a tungsten carbide powder with a particle size of 1.0-1.2 μm, a total carbon content of 6.3%, and an oxygen content of 0.2%. The cemented carbide manufacturing method of the present embodiment comprises the following steps: putting 90 parts by mass of tungsten carbide, 10 parts by mass of cobalt, 0.5 parts by mass of tantalum carbide, 0.2 parts by mass of chromium carbide, and 0.3 parts by mass of vanadium carbide into a ball mill, adding tungsten carbide , cobalt, tantalum carbide, chromium carbide and vanadium carbide total mass of 0.3 parts by mass of alcohol and 0.025wt% oleic acid mixed for 72 hours, unloading, drying, sieving; The forming agent is composed of 2.5 parts by mass of oleic a...

Embodiment 3

[0031] Embodiment 3: The cemented carbide of this embodiment contains at least 85 parts by mass of tungsten carbide, 15 parts by mass of cobalt, 0.3 parts by mass of tantalum carbide, 0.3 parts by mass of chromium carbide, and 0.2 parts by mass of vanadium carbide. The tungsten carbide is a tungsten carbide powder with a particle size of 1.0-1.2 μm, a total carbon content of 6.15%, and an oxygen content of 0.18%. The cemented carbide manufacturing method of the present embodiment comprises the following steps: putting 85 parts by mass of tungsten carbide, 15 parts by mass of cobalt, 0.3 parts by mass of tantalum carbide, 0.3 parts by mass of chromium carbide, and 0.2 parts by mass of vanadium carbide into a ball mill, adding tungsten carbide , cobalt, tantalum carbide, chromium carbide and vanadium carbide total mass of 0.28 parts by mass of alcohol and 0.02wt% polyethylene glycol 4000 mixed for 48 hours, unloading, drying, sieving; SBS forming agent, the powder added with for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com