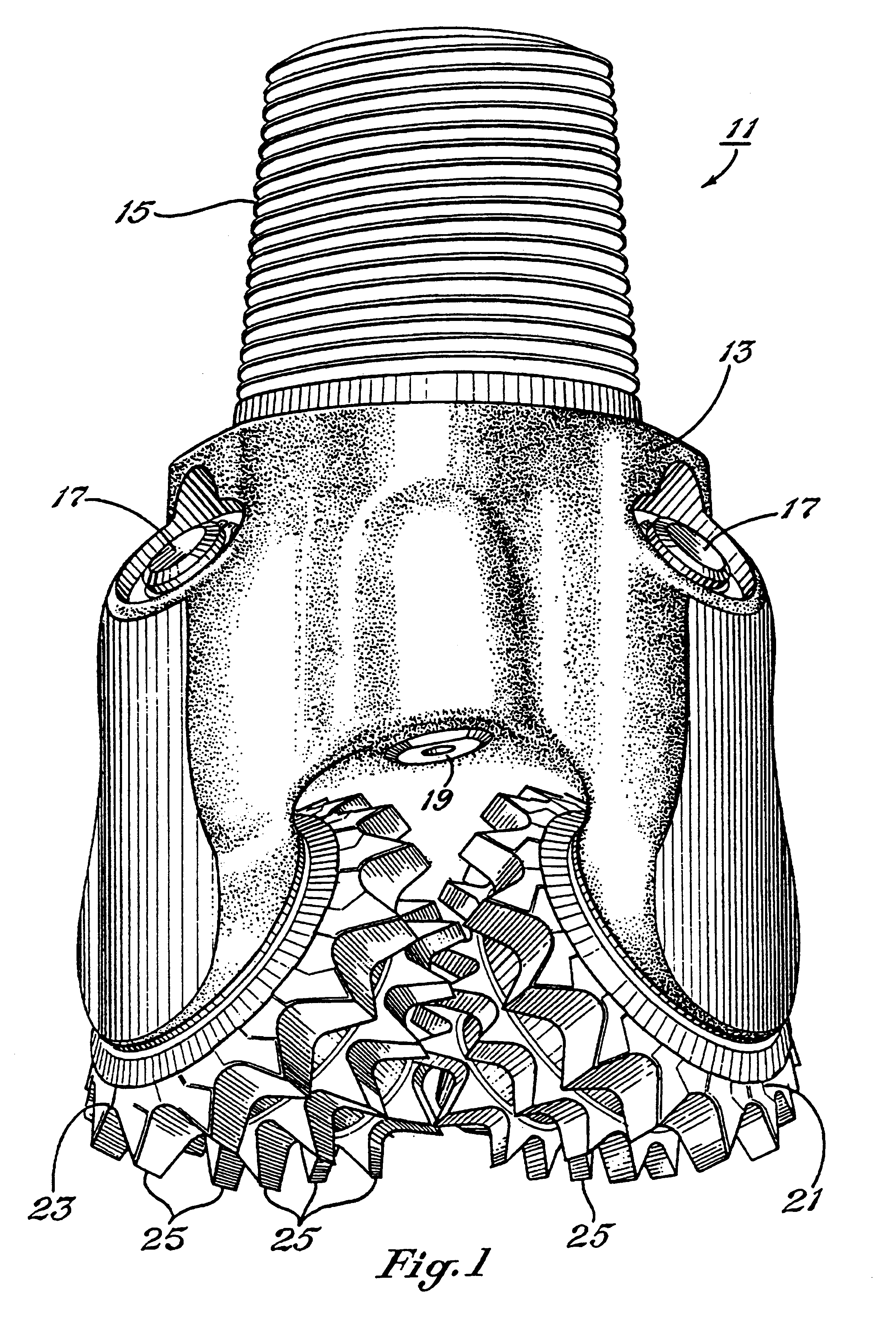

Hardfacing composition for earth-boring bits

a technology of earthboring bits and compositions, applied in the field of earthboring bits hardfacing compositions, can solve the problems of premature cracking and flaking of hardfacing, inadequate hardness and wear resistance, premature eroded hardfacing, etc., and achieve good wear resistance and fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

The following quantities and sizes of granular carbide materials were provided:

Spherical sintered tungsten carbide pellets comprising tungsten carbide particles or grains sintered with a 6% by weight cobalt binder and provided by Kennametal, Inc. of Fallon, Nev., in the following sizes and percentages by weight:

ASTM Mesh Size Range Mean +16 0-5% 3% -16 / +20 40-50% 47% -20 / +30 40-50% 47% -30 0-5% 3%

Crushed sintered tungsten carbide, also provided by Kennametal, Inc., in the following sizes and percentages by weight:

ASTM Mesh Size Range Mean +20 0-5% 3% -20 / +30 90-100% 94% -30 0-5% 3%

Spherical cast carbide pellets, manufactured by WOKA Schweisstechnik GmbH, of Willich, Germany, in the following sizes and percentages by weight:

ASTM Mesh Size Range Mean +40 0-5% 3% -40 / +60 90-100 94% -60 0-5% 4%

The carbide granules were blended, by tumbling in a barrel mill, together with 4% by weight silicomanganese, 0.5% by weight niobium and 0.36% by weight resinox. After the initial blending, alcohol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wall thickness | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com