Tungsten carbide-based hard alloy and preparation method thereof

A cemented carbide and tungsten carbide-based technology, which is applied in the field of alloy materials, can solve the problems of performance degradation of tungsten carbide-based cemented carbide, achieve high hardness and high toughness, less agglomeration and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-20

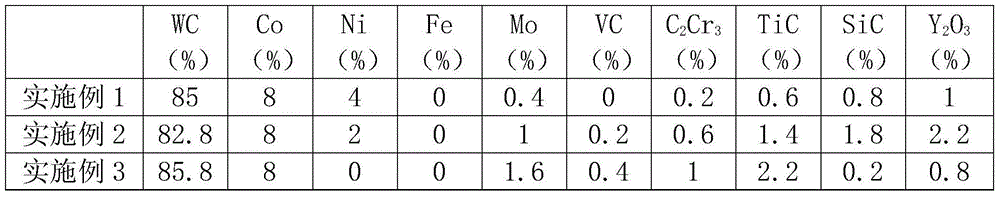

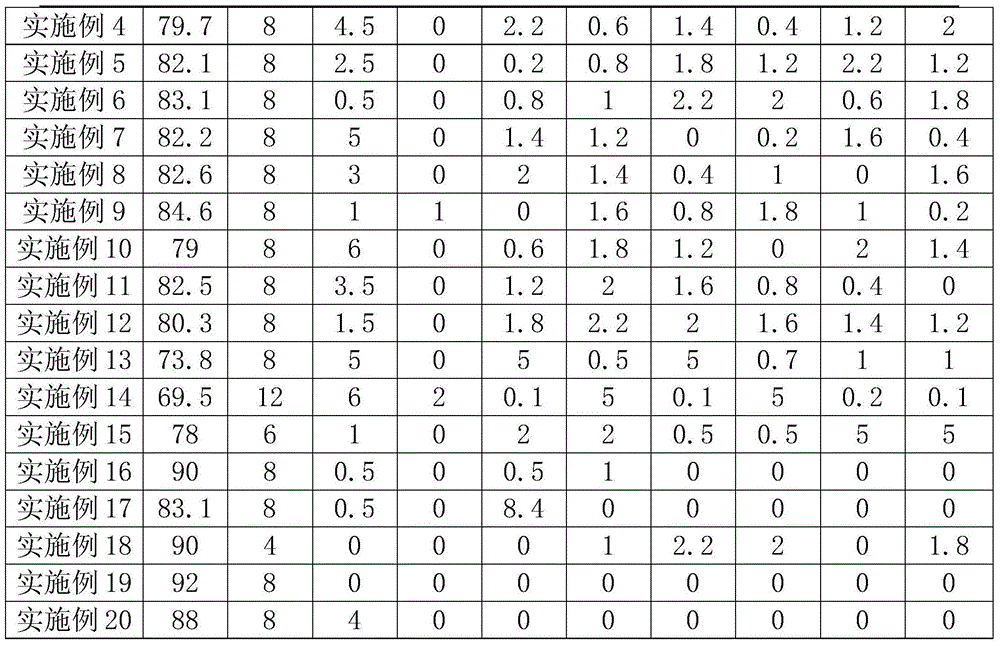

[0024] The tungsten carbide-based cemented carbides provided in Examples 1-20 are respectively made of the substances shown in Table 1 below.

[0025] Each component and the mass percentage that form composite raw material in the embodiment 1-20 of table 1

[0026]

[0027]

[0028] In Table 1, the particle sizes of tungsten carbide, cobalt powder, nickel powder, molybdenum powder, vanadium carbide, chromium carbide, titanium carbide, silicon carbide, and yttrium oxide are all 0.8-1.0 μm, and the purity is above 99.9% (mass percentage).

[0029] The tungsten carbide-based cemented carbide described in the foregoing examples is prepared in the following manner:

[0030] (1) Grinding: Weigh each component separately and pour them into a ball mill jar to mix them together to obtain a composite raw material; then add WC-6Co cemented carbide grinding balls into the ball mill jar, and the WC-6Co hard alloy The mass ratio of high-quality alloy grinding balls to composite raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com