Ferrite material and MXenes composite material and preparation method and application thereof

A technology of ferrite materials and composite materials, applied in the field of composite materials, to achieve the effect of good electrical conductivity and good impedance matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

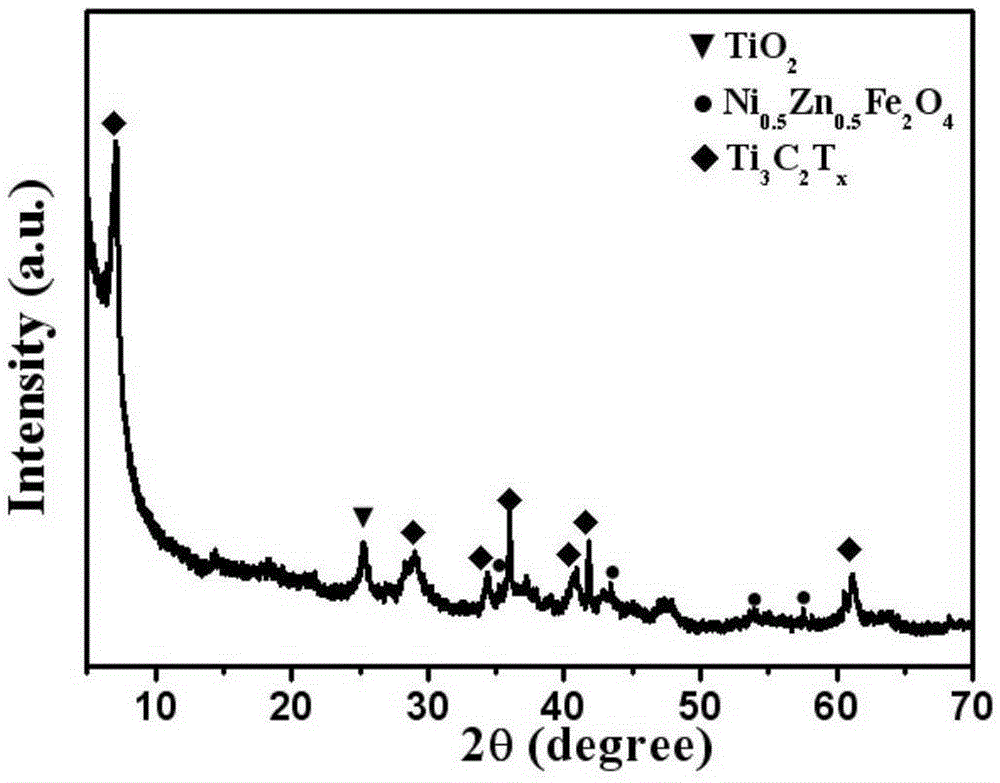

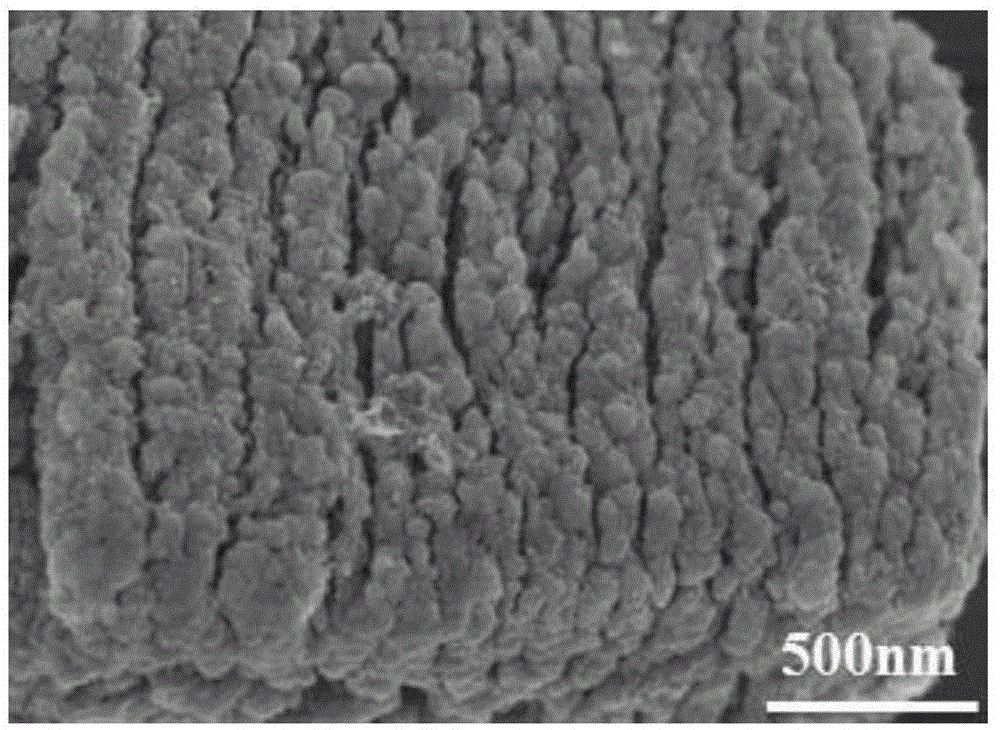

[0031] In this embodiment, the ferrite material is Ni 0.5 Zn 0.5 Fe 2 o 4 , MXenes material is Ti 3 C 2 T x, the ferrite material and MXenes material constitute a composite material, wherein the mass percentage of the ferrite material is 20%, the mass percentage of MXenes is 80%, and its chemical expression is MXenes-20wt.%Ni 0.5 Zn 0.5 Fe 2 o 4 ; and, ferrite molecules grow in situ in the sheet structure of MXenes.

[0032] The concrete preparation method of above-mentioned composite material is as follows:

[0033] (1) Weigh 0.5gTi 3 C 2 T x Dissolved in a supersaturated solution of sodium lignosulfonate, and ultrasonically crushed for 45 minutes to obtain a uniformly dispersed MXenes solution;

[0034] (2) Press ferrite material Ni at room temperature 0.5 Zn 0.5 Fe 2 o 4 The molar ratio of Ni 2+ :Zn 2+ :Fe 3+ =0.5:0.5:2 Weigh Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, was added to the MXenes solution to obtain a mixed solut...

Embodiment 2

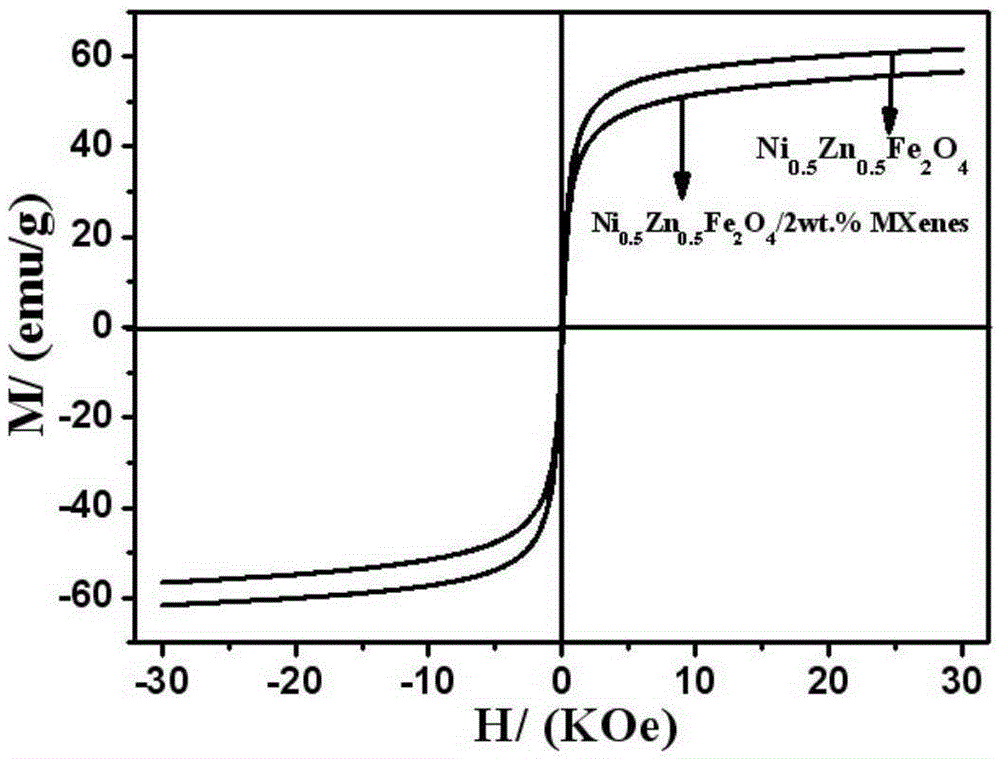

[0040] In this embodiment, the ferrite material is Ni 0.5 Zn 0.5 Fe 2 o 4 , MXenes material is Ti 3 C 2 T x , the ferrite material and MXenes material constitute a composite material, wherein the mass percentage of the ferrite material is 98%, the mass percentage of MXenes is 2%, and its chemical expression is Ni 0.5 Zn 0.5 Fe 2 o 4 -2wt.% MXenes; and, ferrite molecules are grown in-situ in the sheet structure of MXenes.

[0041] The above Ni 0.5 Zn 0.5 Fe 2 o 4 The specific preparation method of -2wt.% MXenes composite material is as follows:

[0042] (1) Weigh 0.5gTi 3 C 2 T x Dissolved in a supersaturated solution of sodium lignosulfonate, and ultrasonically crushed for 45 minutes to obtain a uniformly dispersed MXenes solution;

[0043] (2) Press ferrite material Ni at room temperature 0.5 Zn 0.5 Fe 2 o 4 The molar ratio of Ni 2+ :Zn 2+ :Fe 3+ =0.5:0.5:2 Weigh Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, adding the MXene...

Embodiment 3

[0055] In this embodiment, the ferrite material is CoFe 2 o 4 , the MXenes material is V 3 C 2 T x , the ferrite material and MXenes material constitute a composite material, wherein the mass percentage of the ferrite material is 90%, the mass percentage of MXenes is 10%, and its chemical expression is CoFe 2 o 4 -10wt.% MXenes; and, ferrite molecules are grown in-situ in the sheet structure of MXenes.

[0056] The above-mentioned CoFe 2 o 4 The specific preparation method of -10wt.% MXenes composite material is as follows:

[0057] (1) Weigh 0.5gV 3 C 2 T x Dissolved in a supersaturated solution of sodium dodecylbenzenesulfonate, and ultrasonically crushed for 45 minutes to obtain a uniformly dispersed MXenes solution;

[0058] (2) Press the ferrite material CoFe at room temperature 2 o 4 The molar ratio of Co 2+ :Fe 3+ =1:2 Weigh Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, adding the MXenes solution configured in step (1) to obtain a mixed solution one, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com