Composite bulk material of resin, ferrite and MXenes and preparation method and application thereof

A ferrite material and ferrite technology, applied in the field of composite materials, can solve the problems of high density and limitation, and achieve the effect of good impedance matching performance and good conductivity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

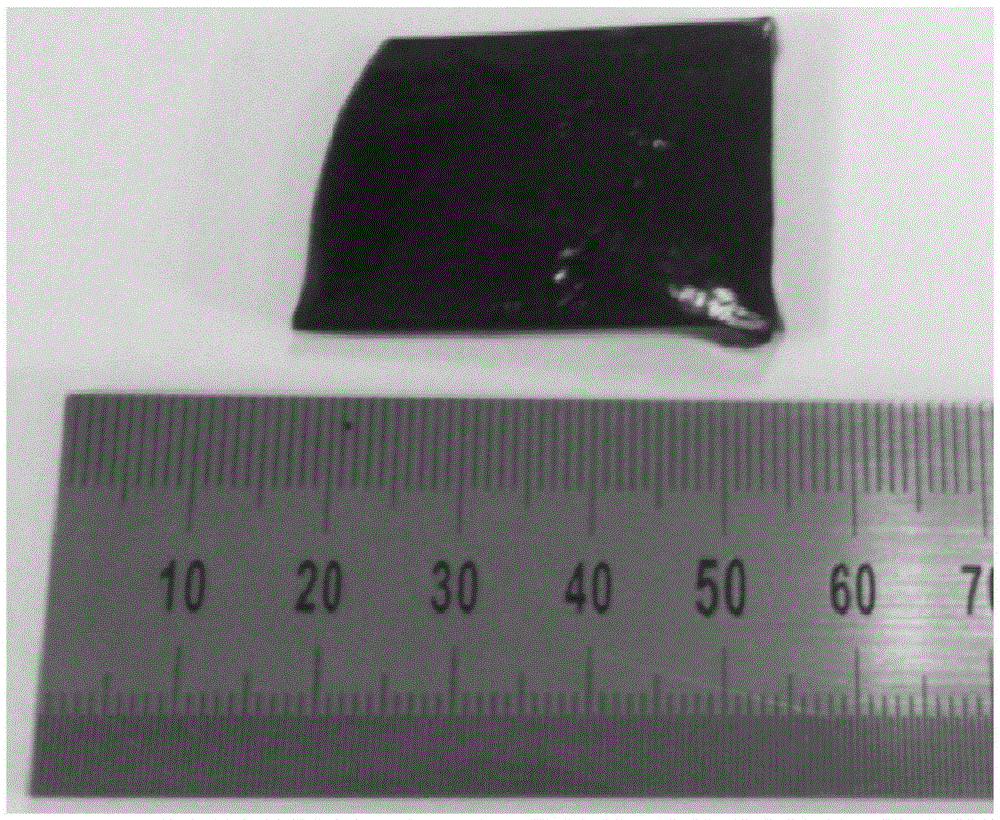

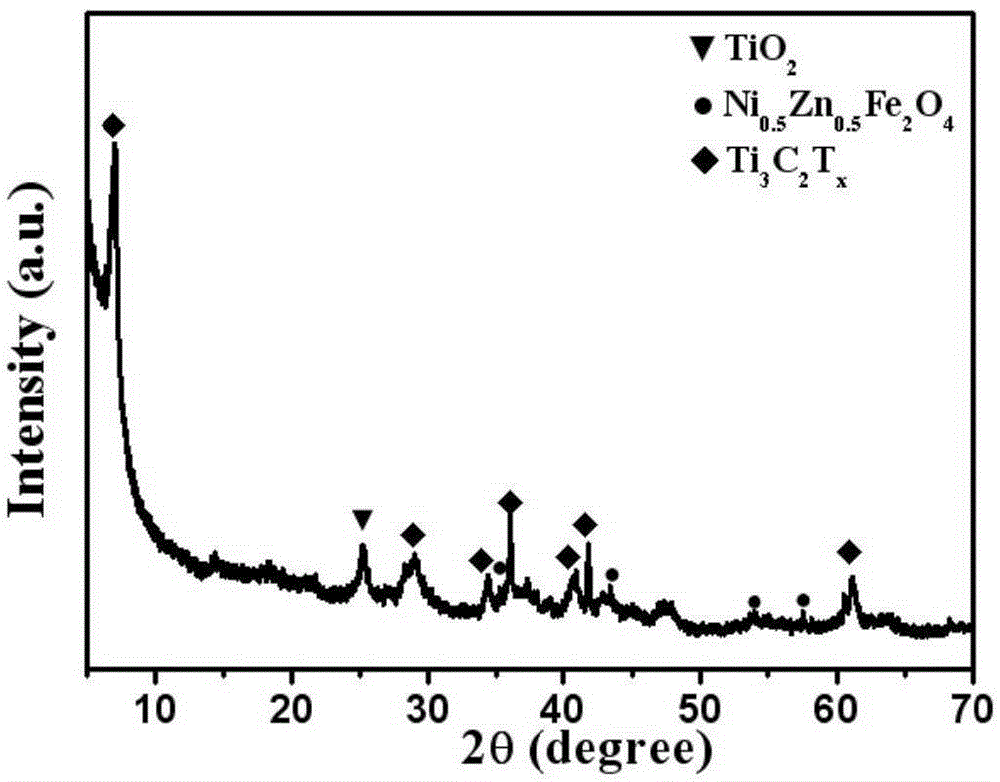

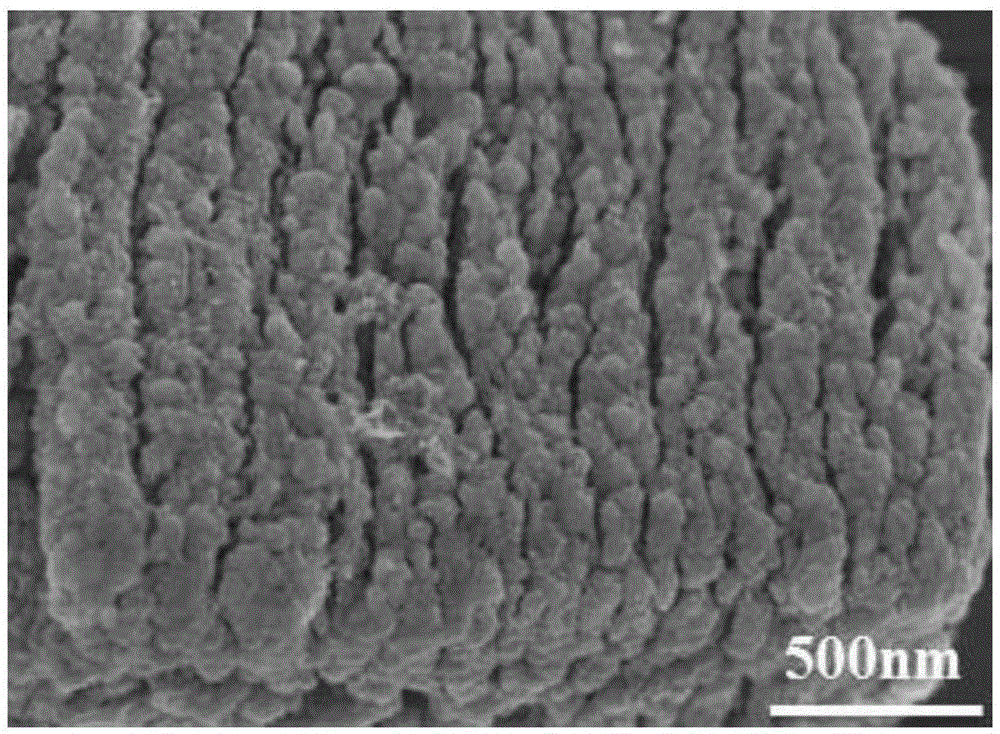

[0038] In this embodiment, the resin is polyetherimide resin (PEI), and the ferrite material is Ni 0.5 Zn 0.5 Fe 2 o 4 , MXenes material is Ti 3 C 2 T x . The ferrite material and MXenes material constitute powder particles. In the powder particles, the mass percentage of ferrite material is 20%, and the mass percentage of MXenes is 80%. Its chemical expression is MXenes-20wt .%Ni 0.5 Zn 0.5 Fe 2 o 4 . Moreover, the powder particles are evenly dispersed in the resin to form a composite block material, the mass of the powder particles accounts for 5% of the total mass of the composite block material, and the mass of the resin accounts for 95% of the total mass of the composite block material.

[0039] The concrete preparation method of above-mentioned composite block material is as follows:

[0040] (1) Weigh 0.5gTi 3 C 2 T x Dissolved in a supersaturated solution of sodium lignosulfonate, and ultrasonically crushed for 45 minutes to obtain a uniformly dispersed ...

Embodiment 2

[0048] In this embodiment, the resin is polyetherimide resin (PEI), and the ferrite material is Ni 0.5 Zn 0.5 Fe 2 o 4 , MXenes material is Ti 3 C 2 T x . The ferrite material and MXenes material constitute powder particles. In the powder particles, the mass percentage of ferrite material is 98%, and the mass percentage of MXenes is 2%. Its chemical expression is Ni 0.5 Zn 0.5 Fe 2 o 4 -2 wt.% MXenes. Moreover, the powder particles are uniformly dispersed in the resin to form a composite block material, the mass of the powder particles accounts for 20% of the total mass of the composite block material, and the mass of the resin accounts for 80% of the total mass of the composite block material.

[0049] The concrete preparation method of above-mentioned composite block material is as follows:

[0050] (1) Weigh 0.5gTi 3 C 2 T x Dissolved in a supersaturated solution of sodium lignosulfonate, and ultrasonically crushed for 45 minutes to obtain a uniformly disperse...

Embodiment 3

[0064] In this embodiment, the resin is epoxy resin (EP), and the ferrite material is CoFe 2 o 4 , the MXenes material is V 3 C 2 T x . The ferrite material and MXenes material constitute powder particles. In the powder particles, the mass percentage of ferrite material is 90%, and the mass percentage of MXenes is 10%. Its chemical expression is CoFe 2 o 4 -10 wt.% MXenes. Moreover, the powder particles are evenly dispersed in the resin to form a composite block material, the mass of the powder particles accounts for 40% of the total mass of the composite block material, and the mass of the resin accounts for 60% of the total mass of the composite block material.

[0065] The concrete preparation method of above-mentioned composite block material is as follows:

[0066] (1) Weigh 0.5gV 3 C 2 T x Dissolved in a supersaturated solution of sodium dodecylbenzenesulfonate, and ultrasonically crushed for 45 minutes to obtain a uniformly dispersed MXenes solution;

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com