Substrate surface processing method, shell and terminal

A treatment method and a technology for the surface of a substrate, which are applied to the device for coating liquid on the surface, special surfaces, pre-treated surfaces, etc., can solve the problems of high requirements for production equipment, complex processes, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

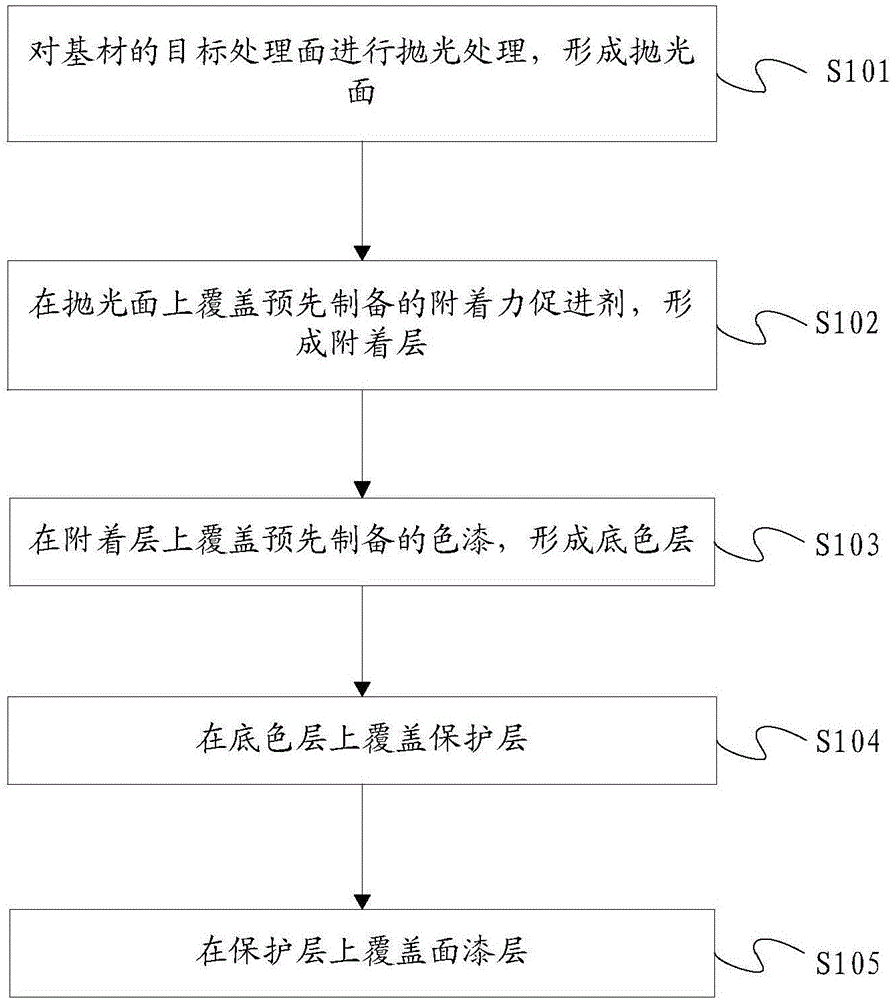

[0041] see figure 1 , this embodiment shows a method for treating the surface of the substrate, combining spray coating and coating process on the surface of the substrate to achieve the effect of ceramic appearance and cold hand feeling. The method of this embodiment improves the traditional ceramic processing technology and the existing problems of spraying ceramic paint shortcoming.

[0042] The substrate surface treatment method of the present embodiment comprises:

[0043] S101. Perform polishing treatment on the target treatment surface of the substrate to form a polished surface;

[0044] S102, covering the pre-prepared adhesion promoter on the polished surface to form an adhesion layer;

[0045] S103, covering the pre-prepared color paint on the adhesion layer to form a base color layer;

[0046] S104, covering the protective layer on the ground color layer;

[0047] S105 , covering the protective layer with a finish paint layer.

[0048] In this embodiment, the m...

Embodiment 2

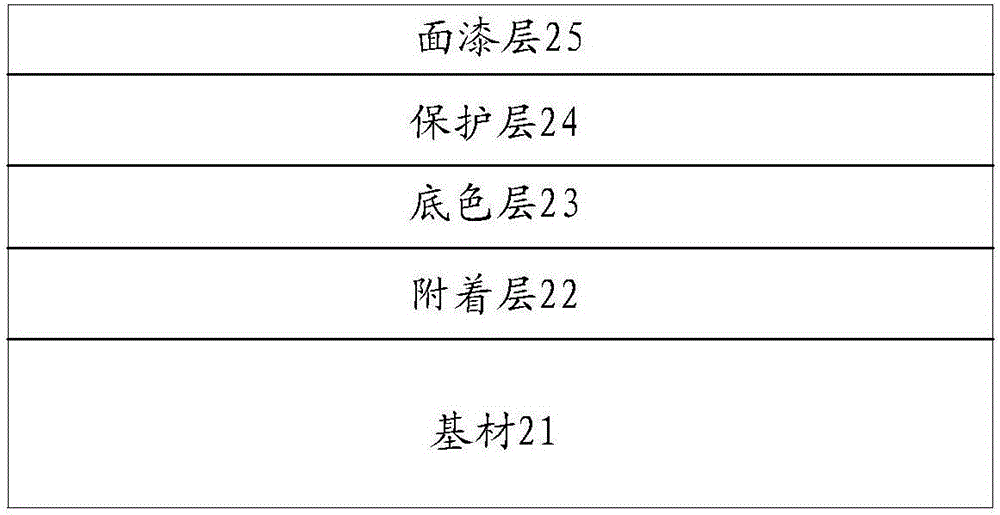

[0068] see figure 2 , this embodiment shows a layer structure of a housing, the housing is made by the substrate surface treatment method shown in Embodiment 1, the housing of this embodiment includes a substrate 21, covered on the polished surface of the substrate Adhesive layer 22, a primer layer 23 covered on the adhesive layer, a protective layer 24 covered on the primer layer, and a top coat layer 25 covered on the protective layer. The above-mentioned layer structure enables the substrate to better imitate the appearance effect of ceramics.

[0069] Wherein, the material of the substrate 21 may be plastic, metal, glass and so on. Wherein, considering that the processed material needs to have the cold feel of ceramics, preferably, the material of the base material 21 may be metal. When the base material 21 obtained by the method of this embodiment is used to manufacture the shell of the terminal, considering the production cost and weight requirements of the base mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com