Emulsified oil-type release agent and preparation method thereof

A technology of release agent and emulsifier, which is applied in the field of emulsified oil release agent and its preparation, which can solve the problems of difficulty in demoulding and cleaning, easy rusting of template storage, complex formula and other problems, and achieve excellent release force , Excellent secondary adhesion, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

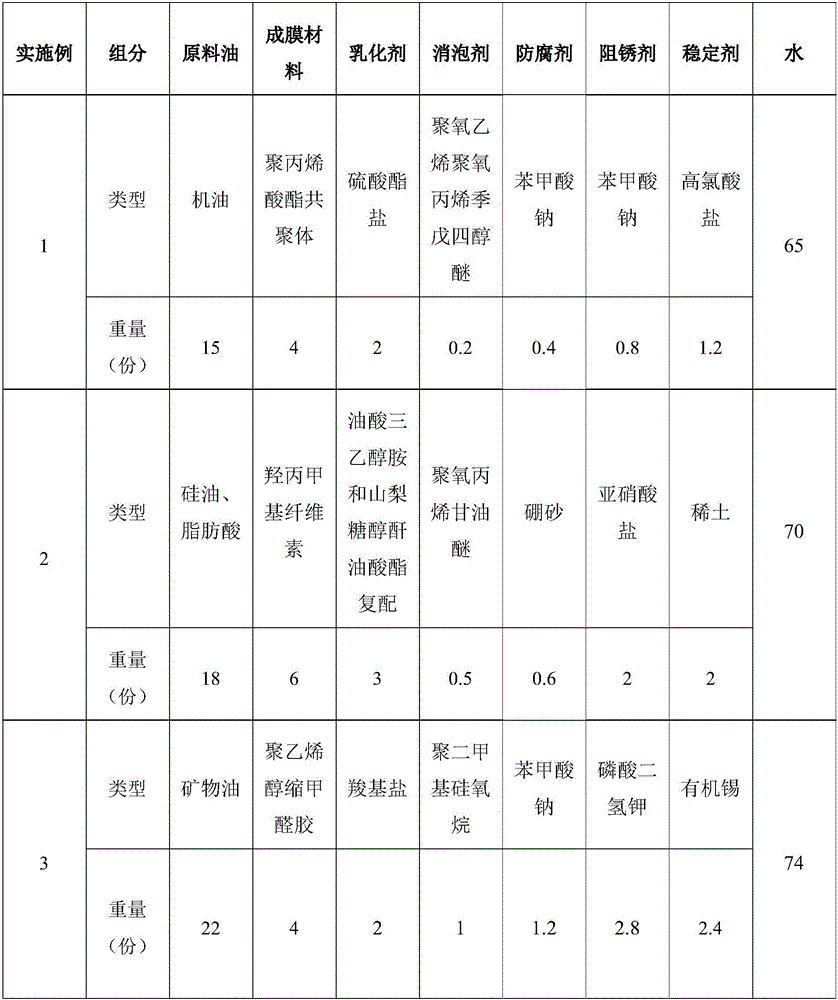

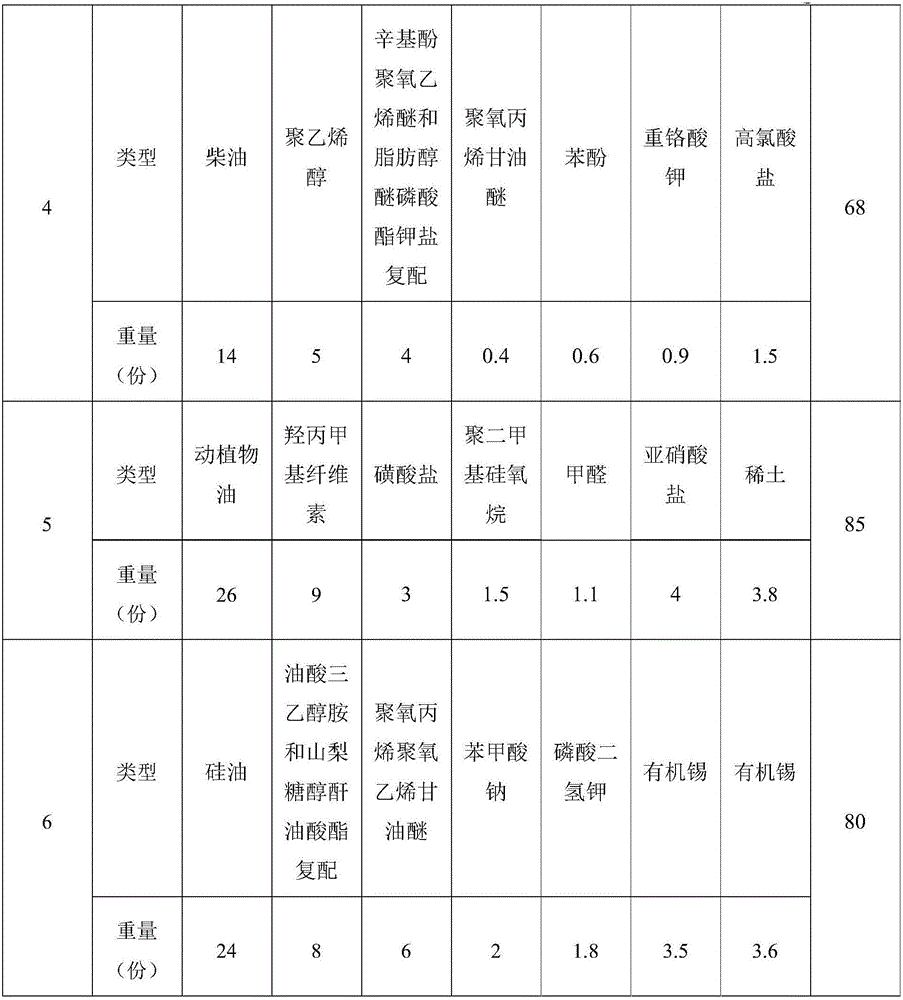

[0023] Formulation: an emulsified oil-based mold release agent, consisting of the following components in parts by weight: 10-30 parts of raw oil, 1-10 parts of film-forming materials, 0.5-6 parts of emulsifier, 0.1-2 parts of defoamer, 0.1-3 parts of preservative, 0.5-5 parts of rust inhibitor, 1-5 parts of stabilizer and 60-90 parts of water; the molecular weight of the film-forming material is less than 2000.

[0024] The specific parameters of the emulsified oil release agent formulations of Examples 1 to 6 are listed in the form of a table, and the details are shown in Table 1:

[0025] The specific parameters of the emulsified oil mold release agent formulations of Table 1 Examples 1-6

[0026]

[0027]

[0028] The preparation method of emulsified oil release agent, described method comprises the steps:

[0029] (1) emulsified crude oil, emulsifier, water are successively put into the reactor for stirring and emulsification;

[0030] (2) Under the state of mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com