Simple method for preparing polyethylene wax from waste plastic

A technology of polyethylene wax and waste plastics, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems that are not suitable for long-distance transportation and large-scale centralized treatment, and are not suitable for recycling and utilization by small private enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

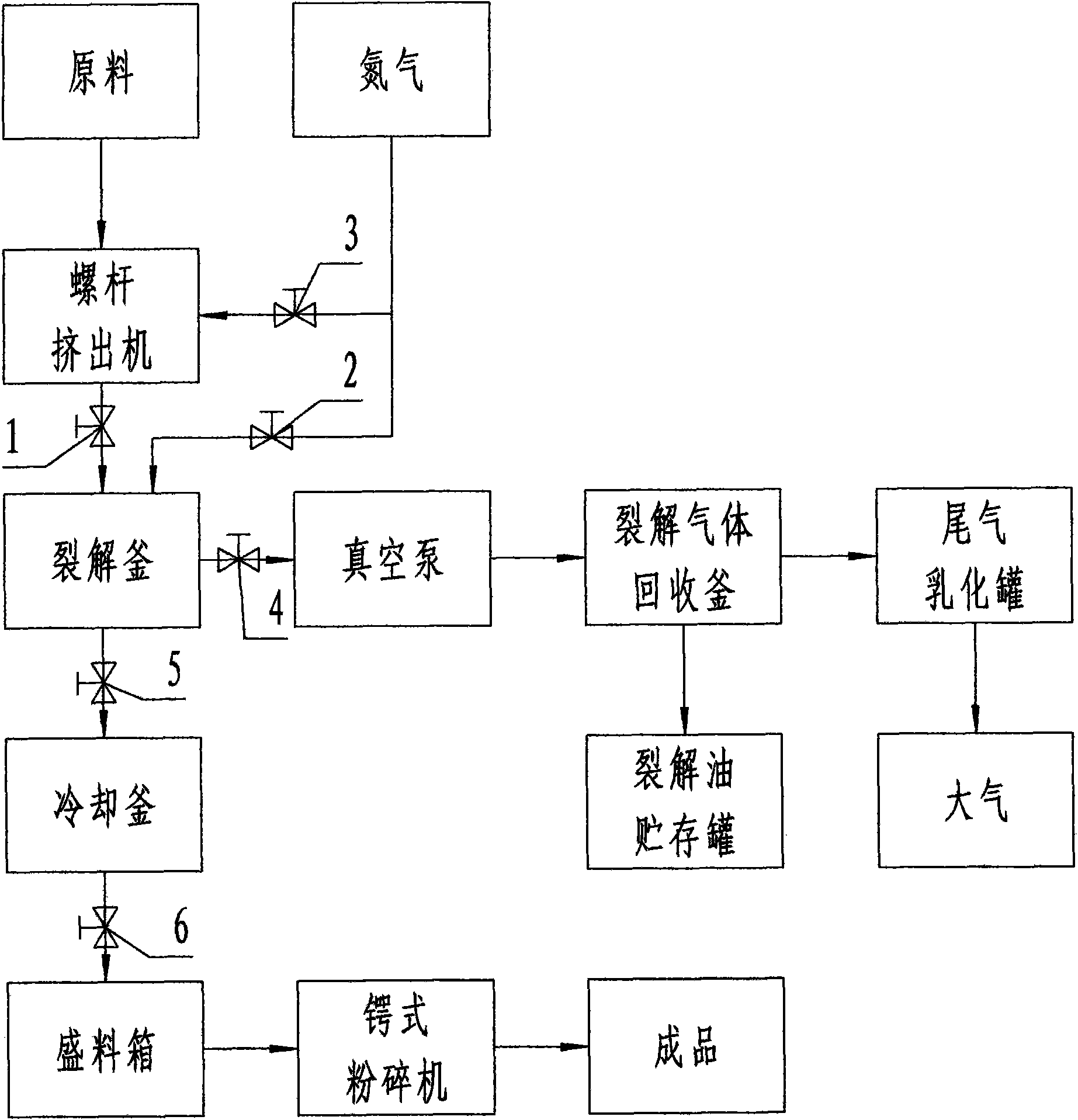

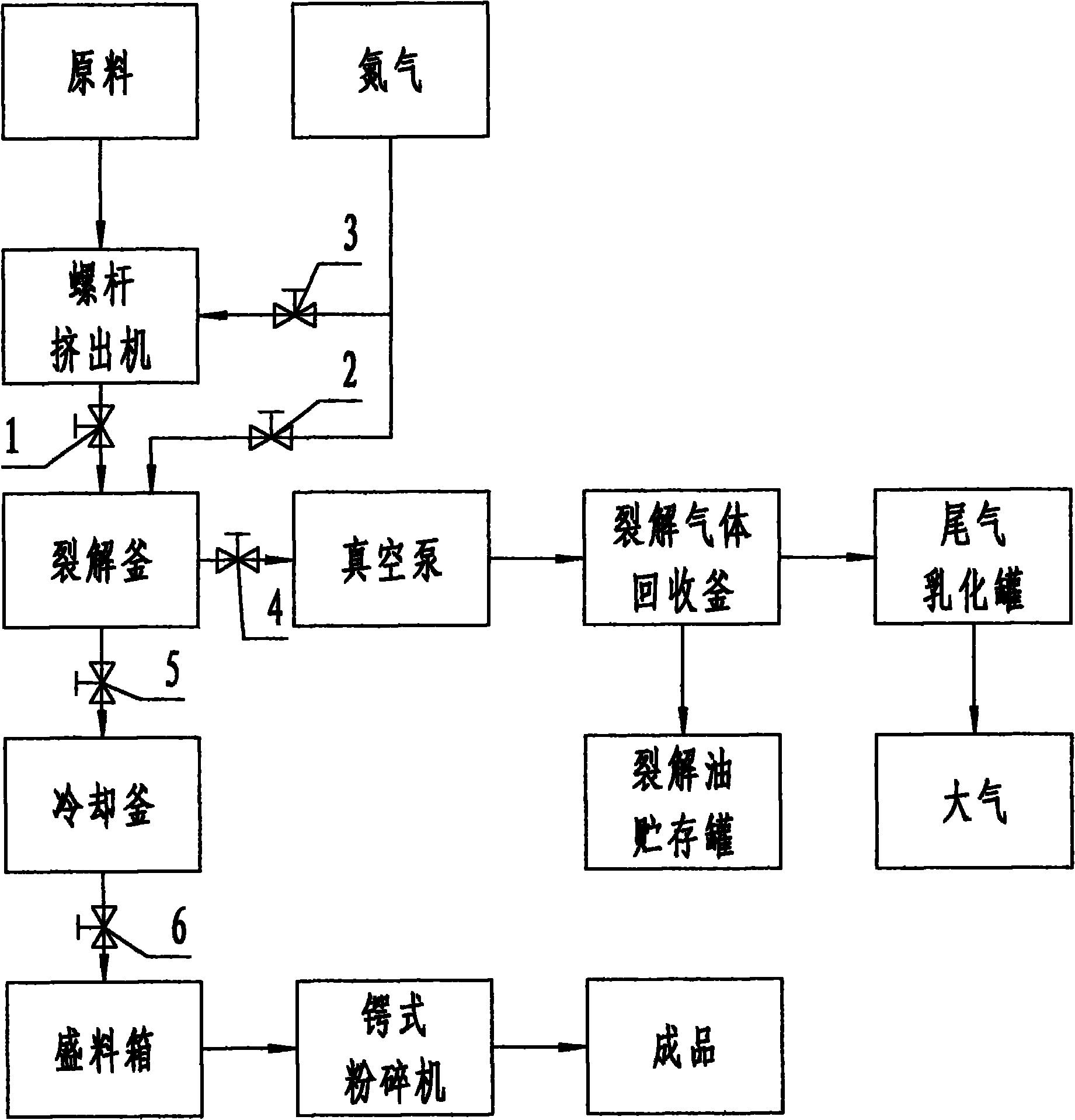

[0036] Examples, see figure 1 ;

[0037] Product Name: Polyethylene Wax

[0038] Raw materials: waste polyethylene plastic particles; nitrogen purity is 99%;

[0039] conditions, equipment

[0040] Ambient air pressure: one atmosphere;

[0041] Ambient temperature: room temperature;

[0042] Preparation equipment: screw extruder, pyrolysis kettle, cooling kettle, material storage box, collar type pulverizer, vacuum pump, pyrolysis gas recovery kettle, pyrolysis oil storage tank, tail gas emulsification tank;

[0043] Process flow:

[0044] Preheating and flushing the screw extruder

[0045] Preheat the barrel of the screw extruder. The barrel is heated in steps of eight temperature zones. The temperature from the hopper mouth to the extrusion nozzle is 150, 200, 250, 300, 350, 400, 450, and 500°C; after reaching the temperature, Start the screw of the screw extruder, open the nitrogen valve of the extruder 3 and flush the barrel and screw with nitrogen, and finish;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com