Viscous oil emulsification and viscosity reduction agent

A technology for emulsifying viscosity-reducing and heavy oil, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of no reports, etc., and achieve the effects of moderate emulsification cost, strong resistance to mineral salt, and low viscosity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

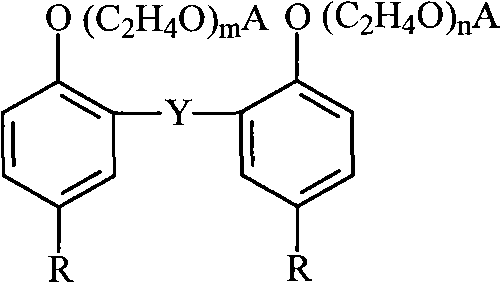

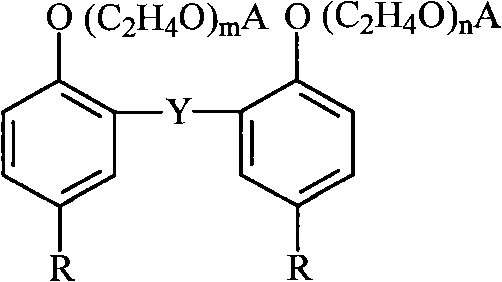

[0034] Taking by weighing 80 DEG C of viscosity is 73000mPa.s, asphaltenes content is 34.47% by weight of Xinjiang Tahe super thick crude oil 100g, with 0.05g average molecular weight is 10000 petroleum sulfonate condensate (PF200A, Huiyuan synthetic agent factory product), 0.7g nonylphenol ethoxylate (10) carboxylate dimer, wherein Y is -(CH 2 ) 2-, 0.01g n-butanol and 0.5g water are made into an emulsified viscosity reducer, diluted with 43g of high salinity hard water (total salinity 200000mg / l, wherein the concentration of calcium and magnesium ions is 20000mg / l) and then added to the above thickened In the oil, after stirring at 80°C for 5 minutes, the viscosity of the emulsified heavy oil was tested with a Hakke VT550 rotary viscometer (100 rpm). The test results are shown in Table 1.

example 2

[0036] Taking by weighing 80 ℃ of viscosity is 640880mPa.s, asphaltene content is 38.87% by weight of Xinjiang Tahe super thick crude oil 100g, with 0.05g average molecular weight is sodium lignosulfonate of 1000, 1.2g nonylphenol polyoxyethylene ether ( 7) Phosphate salt dimer, wherein Y is-(CH 2 CH 2 O) 2 -, 0.01g cyclohexanol and 1.5g water are made into emulsified viscosity reducer, diluted with 66g of high salinity hard water (total salinity 200000mg / l, wherein the concentration of calcium and magnesium ions is 20000mg / l) and added to the above thickened In the oil, after stirring at 80°C for 5 minutes, the viscosity of the emulsified heavy oil was tested with a Hakke VT550 rotary viscometer (100 rpm). The test results are shown in Table 1.

example 3

[0038] Take by weighing 50 ℃ viscosity be 64160mPa.s, colloid and asphaltene content are respectively 23.9 weight % and 3.9 weight % Shengli Caoqiao heavy oil 100g, 0.01g average molecular weight is 1000 sodium lignosulfonate, 0.15g octane phenoxyethylene ether (3) sulfonate dimer, wherein Y is -S(CH 2 ) 2 S-, 0.01g ethanol, 0.2g water to make emulsified viscosity reducer, dilute with 43g high salinity hard water (total salinity 200000mg / l, in which calcium and magnesium ion concentration is 20000mg / l) and add to the above heavy oil After stirring at 50°C for 5 minutes, the viscosity of the emulsified heavy oil was tested with a Hakke VT550 rotational viscometer (100 rpm). The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com