Method for reducing viscosity of heavy oil by emulsification

A technology for emulsifying viscosity-reducing and heavy oil, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc. It can solve problems such as inapplicability, and achieve strong mineral salt resistance, low viscosity, and moderate emulsification cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

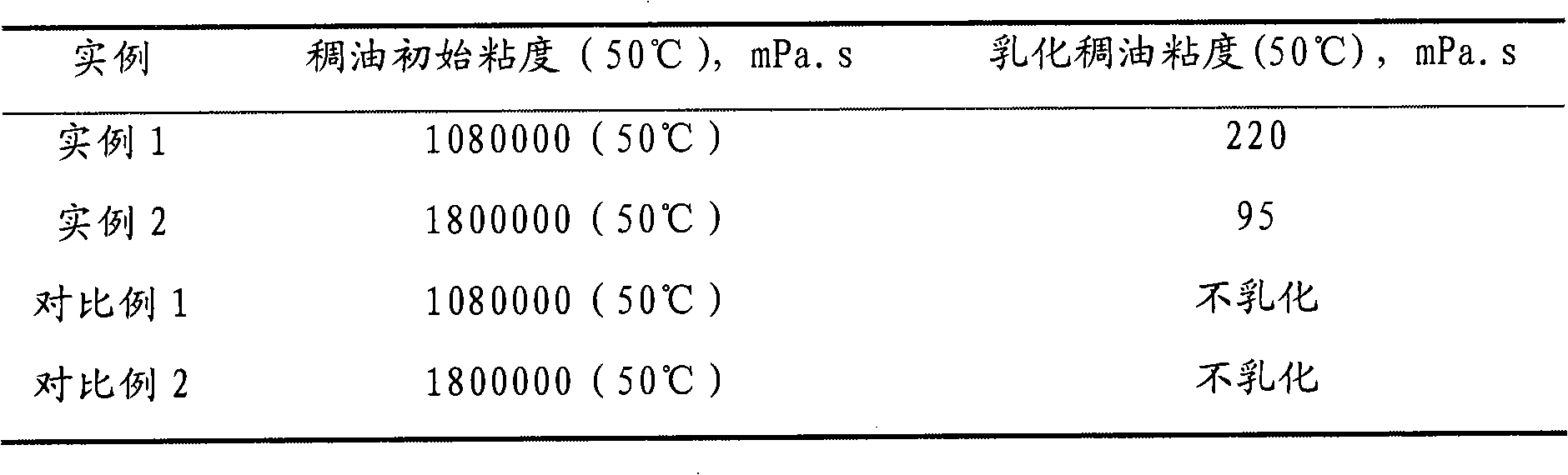

example 1

[0034]Weigh 1g of naphtha as agent A, mix it with 10g of Xinjiang Tahe super thick crude oil with a viscosity of 1,080,000mPa.s at 50°C, and then weigh 0.08g of octylphenol polyoxyethylene polyoxypropylene ether sulfonate , 0.01g of sodium petroleum sulfonate formaldehyde condensate is dissolved in 4.24g of formation water with a total salinity of 45000mg / L, and is made into an aqueous solution of agent B. Add the aqueous solution of Agent B to the mixed oil of Agent A and heavy oil, and stir at 60°C for 2 minutes to form a stable oil-in-water emulsion. Measure the viscosity of the emulsion. The results are shown in Table 1.

example 2

[0036] Weigh 10g of kerosene as agent A, mix it with 10g of Xinjiang Tahe super thick crude oil with a viscosity of 1,800,000mPa. Dissolve 1 g of petroleum calcium sulfonate formaldehyde condensate in 8.57 g of formation water with a total salinity of 200,000 mg / L to prepare an aqueous solution of agent B. Add the aqueous solution of Agent B to the mixed oil of Agent A and heavy oil, and stir at 60°C for 2 minutes to form a stable oil-in-water emulsion. Measure the viscosity of the emulsion. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com