3D printing antibacterial repair dental medical material and preparation method thereof

A 3D printing and dental technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of slow development of composite functional materials, and achieve the effect of overcoming the reduction of bactericidal efficacy, good antibacterial effect and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

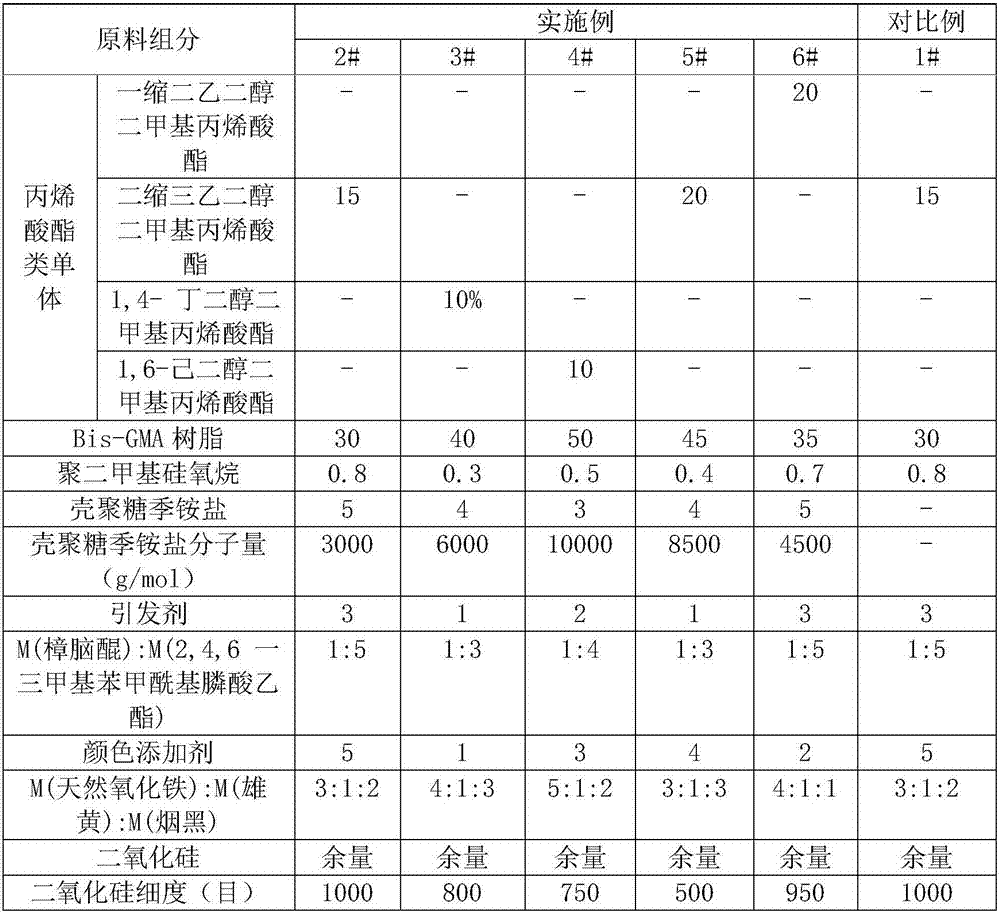

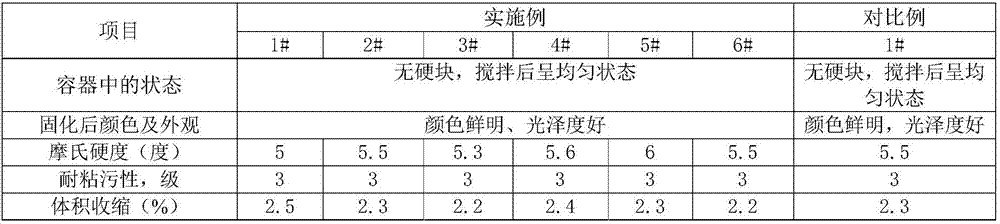

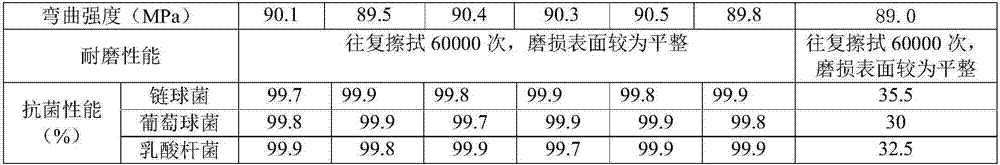

Embodiment 1

[0031] A 3D printing antibacterial restoration dental medical material, in parts by weight, includes the following components:

[0032] Diethylene glycol dimethacrylate monomer 15%

[0033] Bis-GMA resin 40%

[0034] Dimethicone 0.5%

[0035] Chitosan quaternary ammonium salt 4%

[0036] Initiator 2%

[0037] Color Additive 3%

[0038] 800 mesh silica 35.5%

[0039] The molecular weight of the chitosan quaternary ammonium salt described therein is 5000g / mol; The initiator is composed of camphorquinone and 2,4,6-trimethylbenzoylphosphonic acid ethyl ester in a mass ratio of 1:4; the color additive is It is composed of natural iron oxide, realgar and smoke black in a mass ratio of 4:1:1.

[0040] The preparation method of 3D printing antibacterial restoration dental medical material comprises the following steps:

[0041] (1) Stir and mix 80% of the acrylate monomer in the above formula ratio with Bis-GMA resin and defoamer at a temperature of 40-50°C;

[0042] (2) The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com