Preparation method for black micro arc oxidation film layers of surfaces of pure aluminum and aluminum alloys

A technology of micro-arc oxidation on the surface of aluminum alloy, applied in the direction of anodic oxidation, etc., can solve the problem of preparing black micro-arc oxidation film on the surface of pure aluminum that has not yet been seen, and achieve the effect of realizing diversified colors and meeting decorative needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

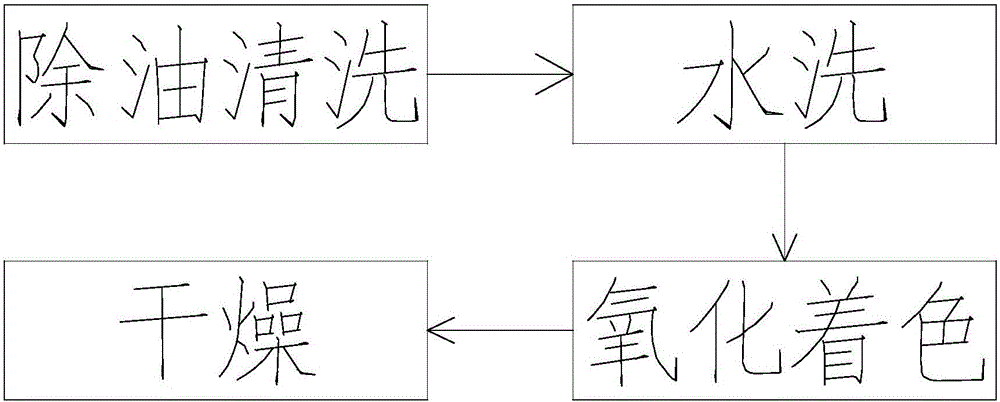

Method used

Image

Examples

Embodiment 1

[0042] The steps and conditions are as follows:

[0043] a) Reagents used

[0044] Main film forming agent: sodium phosphate;

[0045] pH regulator: Potassium Hydroxide;

[0046] Colorants: sodium tungstate, sodium molybdate and ammonium metavanadate;

[0047] The chemical reagents used are of analytical grade, and distilled water is used when preparing the treatment solution.

[0048] b) equipment used

[0049] MH-15kW micro-arc oxidation power supply, electrolyzer, stirring system and cooling system;

[0050] The material is pure aluminum.

[0051] c) Preparation of micro-arc oxidation coloring treatment solution

[0052] First pour distilled water into the equipment, add reagents at room temperature, the order and concentration range of reagents are: sodium phosphate 20g / L, potassium hydroxide 2g / L, sodium tungstate 8g / L, sodium molybdate 8g / L and partial Ammonium vanadate 4g / L, and keep stirring during the addition process. After one reagent is completely dissolved,...

Embodiment 2

[0063] a) The reagent used is the same as in Example 1.

[0064] b) equipment used

[0065] MH-15kW micro-arc oxidation power supply, electrolyzer, stirring system and cooling system;

[0066] The material is LY12 aluminum alloy.

[0067] c) Preparation of micro-arc oxidation coloring treatment solution

[0068] First pour distilled water into the equipment, add reagents at room temperature, the order and concentration range of reagents are: sodium phosphate 30g / L, potassium hydroxide 2g / L, sodium tungstate 8g / L, sodium molybdate 8g / L and partial Ammonium vanadate 5g / L, and keep stirring during the addition process. After one reagent is completely dissolved, add another reagent. After the addition is complete, continue stirring until the reagent is completely dissolved.

[0069] d) Implementation of micro-arc oxidation process

[0070] 1) LY12 aluminum alloy surface degreasing cleaning

[0071] Put the test piece into the sodium hydroxide solution with a concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com