Synthetic fluorophlogopite and preparation method thereof

A technology for synthesizing fluorine phlogopite and fluorine phlogopite, which is applied in the direction of chemical instruments and methods, silicon compounds, non-metallic elements, etc., can solve the problems of cost increase, low efficiency, and weak competitiveness, so as to save refractory bricks and reduce Effect of wasting and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

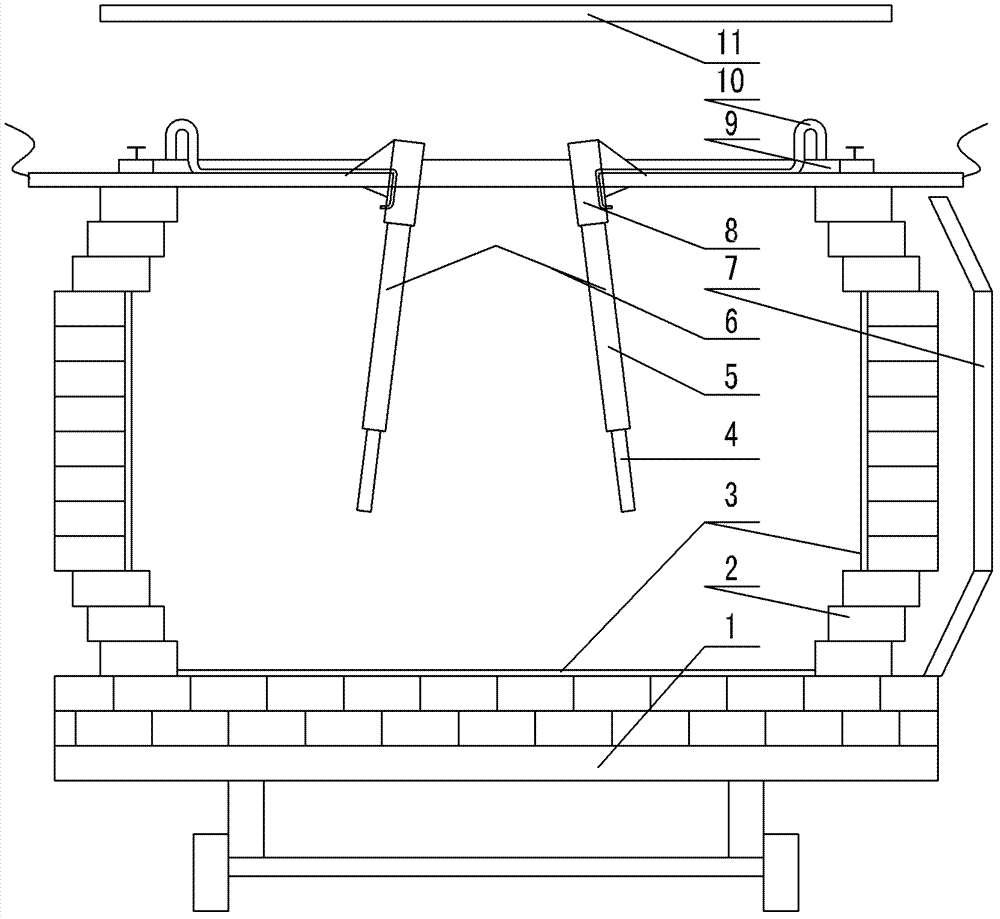

Image

Examples

example 1

[0058] The ingredients are as follows

[0059] name

purity

Specification

formula

Remark

Potassium fluorosilicate K 2 SiF 6

>99%

120 mesh

18.5Kg

no lumps

>97%

0~1mm

30.1Kg

Fe<0.3%

Alumina Al 2 o 3

>99%

120 mesh

11.75Kg

Calcined

>99%

natural particles

3.45Kg

no lumps

Quartz sand SiO 2

>99.5%

40~70 mesh

36.2Kg

Fe<0.1%

[0060] Weigh about 100Kg of raw materials according to the above formula, put it into a V-shaped mixer and mix for 30 minutes. Use clay refractory bricks to form a small kiln with an inner size of 300×400×400mm, lined with a layer of 0.5mm thick graphite paper. Insert the stainless steel and graphite combined electrode into the small furnace and fix it, fill up the mixture, start to energize, and slowly increase the power from 0 to 30Kw. When the...

example 2

[0064] The ingredients are as follows

[0065] name

purity

Specification

formula

Remark

Potassium fluorosilicate K 2 SiF 6

>99%

120 mesh

50.4Kg

no lumps

>97%

0~1mm

82.2Kg

Fe<0.3%

Alumina Al 2 o 3

>99%

120 mesh

32.1Kg

Calcined

Potassium Carbonate K 2 CO 3

>99%

natural particles

9.3Kg

no lumps

Quartz sand SiO 2

>99.5%

40~70 mesh

98.7Kg

Fe<0.1%

Titanium dioxide TiO 2

>99%

200 mesh

17.4Kg

Rutile type

>99%

120 mesh

9.9Kg

no lumps

[0066] Weigh about 300 kg of raw materials according to the formula, mix them with a V-shaped mixer for about 30 minutes, make them fully mixed, and use refractory bricks to form a small kiln with an inner size of 450×500×450mm, and use 0.5mm thick inner wall and bottom Graphite paper...

example 3

[0069] The ingredients are as follows

[0070] name

purity

Specification

formula

Remark

Potassium fluorosilicate K 2 SiF 6

>99%

120 mesh

49.56Kg

no lumps

>97%

0~1mm

80.64Kg

Fe<0.3%

Alumina Al 2 o 3

>99%

120 mesh

31.5Kg

Calcined

Potassium Carbonate K 2 CO 3

>99%

natural particles

9.24Kg

no lumps

Quartz sand SiO 2

>99.5%

40~70 mesh

96.9Kg

Fe<0.1%

Fe2O3 2 o 3

>99%

200 mesh

32.16Kg

no lumps

[0071] Weigh about 300 kg of raw materials according to the formula, mix them with a V-shaped mixer for about 30 minutes, make them fully mixed, and use refractory bricks to form a small kiln with an inner size of 450×500×450mm, and use 1.0mm thickness for the inner wall and bottom Graphite paper, insert the combined electrode, put it into the furnace from the top and fix it....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com