Micro-plastic separation method and device

A separation method and technology for microplastics, which are applied in wet separation, solid separation, plastic recycling, etc., to achieve the effects of reduced use cost, high separation efficiency, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

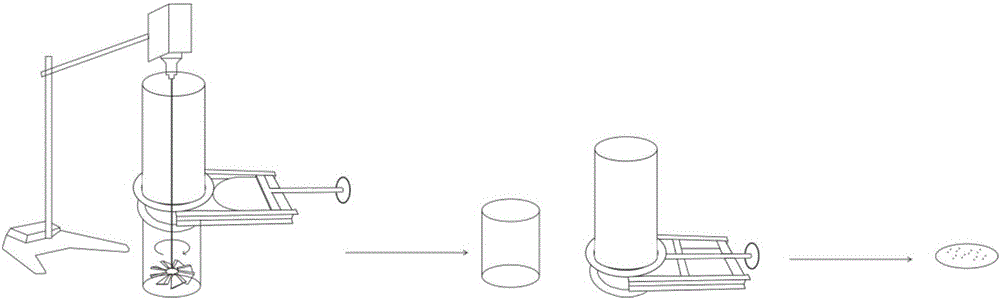

[0045] see figure 1 , the present invention provides a method for separating microplastic pollutants. First, the sediment is pre-treated, and the sediment sample processed by drying (3 The density solution (the density can be adjusted according to the needs). At this time, the gate valve is in an open state. Turn on the stirrer, fully stir the sediment and the density solution and stir for a period of time (30 minutes), and then remove the external stirrer. The solution was left to stand for 24 hours. Close the flapper valve, separate the lower part of the columnar body from the flapper valve, and remove the sediment at the bottom. Use a suction filter to filter the solution in the upper part of the column and the microplastic particles floating on the upper layer of the liquid on the glass fiber filter membrane. Observe the microplastic particles on the filter membrane with the naked eye or with the help of a stereo microscope.

Embodiment 2

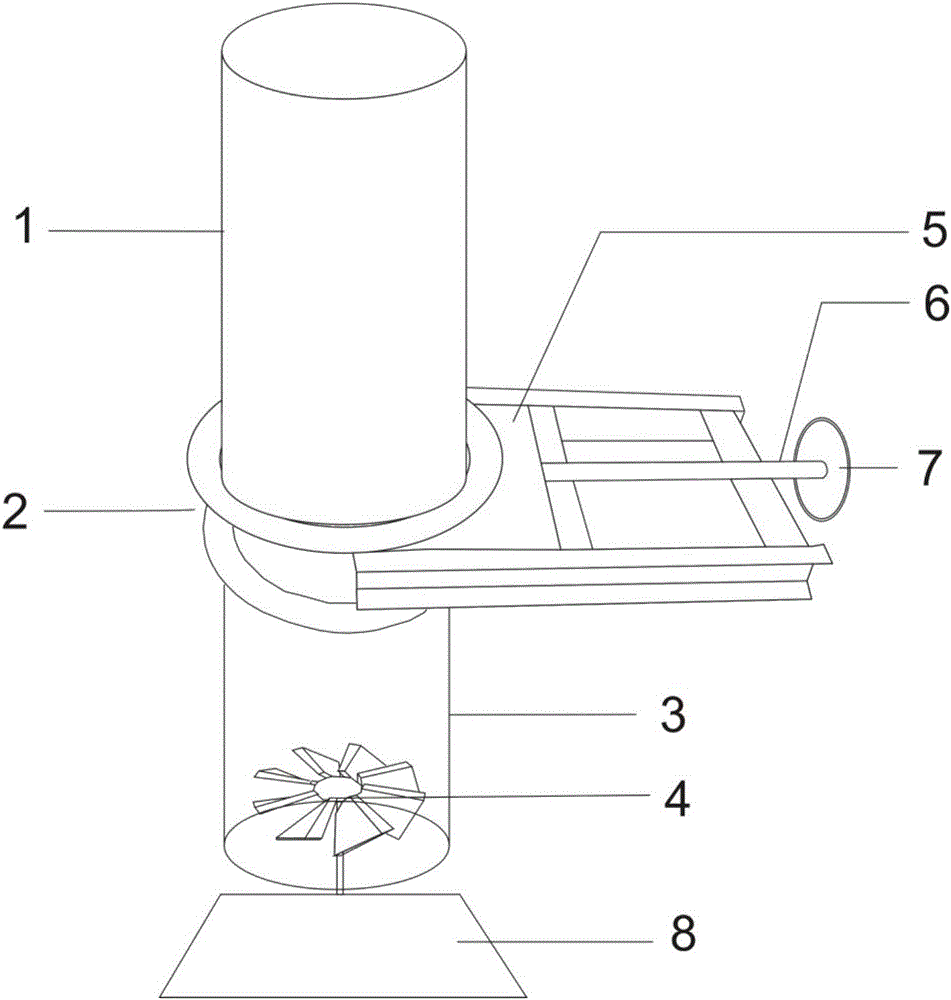

[0047] like figure 2 As shown, the present invention provides a device for separating microplastics from sediment. Wherein, the average height of the upper columnar body 1 and the lower columnar body 3 is 15cm, and the average diameter is 10cm. The middle joint is a flapper valve 2, and the bottom has a stirring blade 4 and a motor 8 connected to the stirring blade. The upper columnar body 1 and the lower columnar body 3 are spliced together to form a columnar body. The function of the columnar body is to provide a container for containing the sediment and the density solution; the function of the built-in agitator is to provide stirring force so that the sediment and the density solution can be fully Mix, and let the microplastic particles with lower density gradually float on the upper layer of the solution; the function of the flapper valve 2 is to separate the upper layer solution from the lower layer of sediment after the solution has stood still, and then use the flap...

Embodiment 3

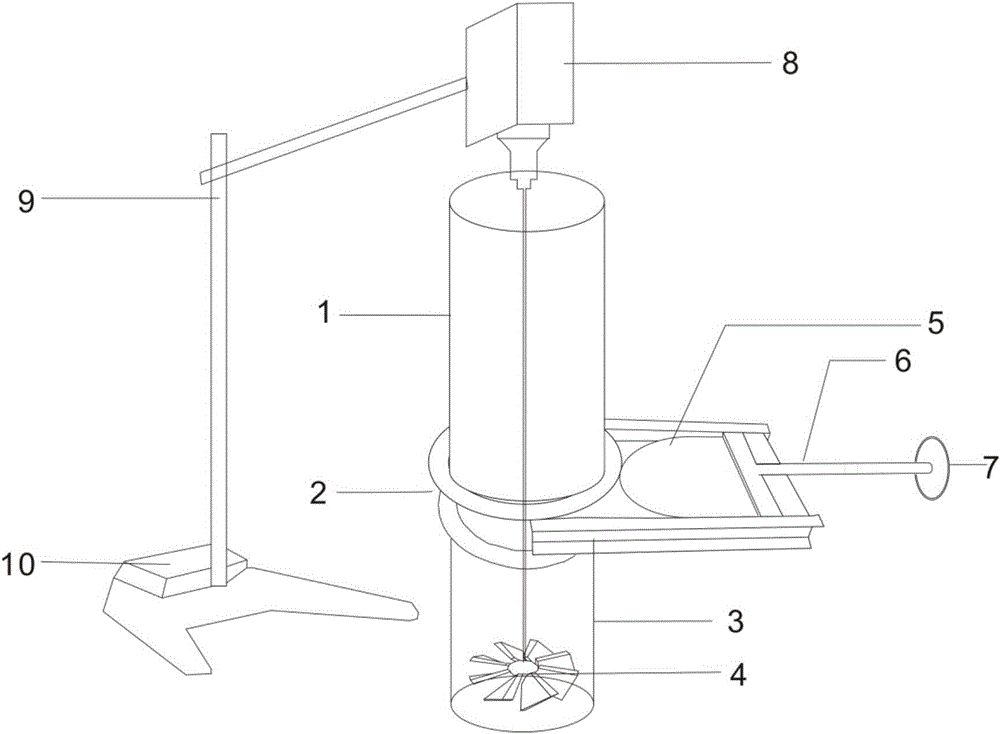

[0049] see image 3 , a device for separating microplastics from sediments provided by the present invention. In order to increase the single-time processing capacity, the volume of the columnar body can increase the upper columnar body 1 and the lower columnar body 3, and the density of the separated microplastics is less than 1.7g / cm 3 , the single treatment volume should be able to fully mix the sediment and the density solution, and the volume of the sediment should not exceed 50% of the volume of the lower column; add the density solution and start the agitator. The stirrer adopts an external metal stirrer, and the metal stirrer includes a base 10, a vertical rod 9, a motor 8 and a stirring blade 4; the vertical rod 9 is arranged on the base 10; the motor 8 is arranged on the vertical rod 9; the motor 8 and the stirring The leaves 4 are connected and drive the stirring leaves 4 to rotate; the rotation speed should be slow at first and then fast until the sediment is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com