Method producing light fuel oil and propylene from poor residual oil

A technology for light fuel oil and residual oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, and hydrocarbon cracking to produce hydrocarbons, etc., can solve the problems of low yield of light oil and application limitation of coking process, etc., and achieve the effect of efficient utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

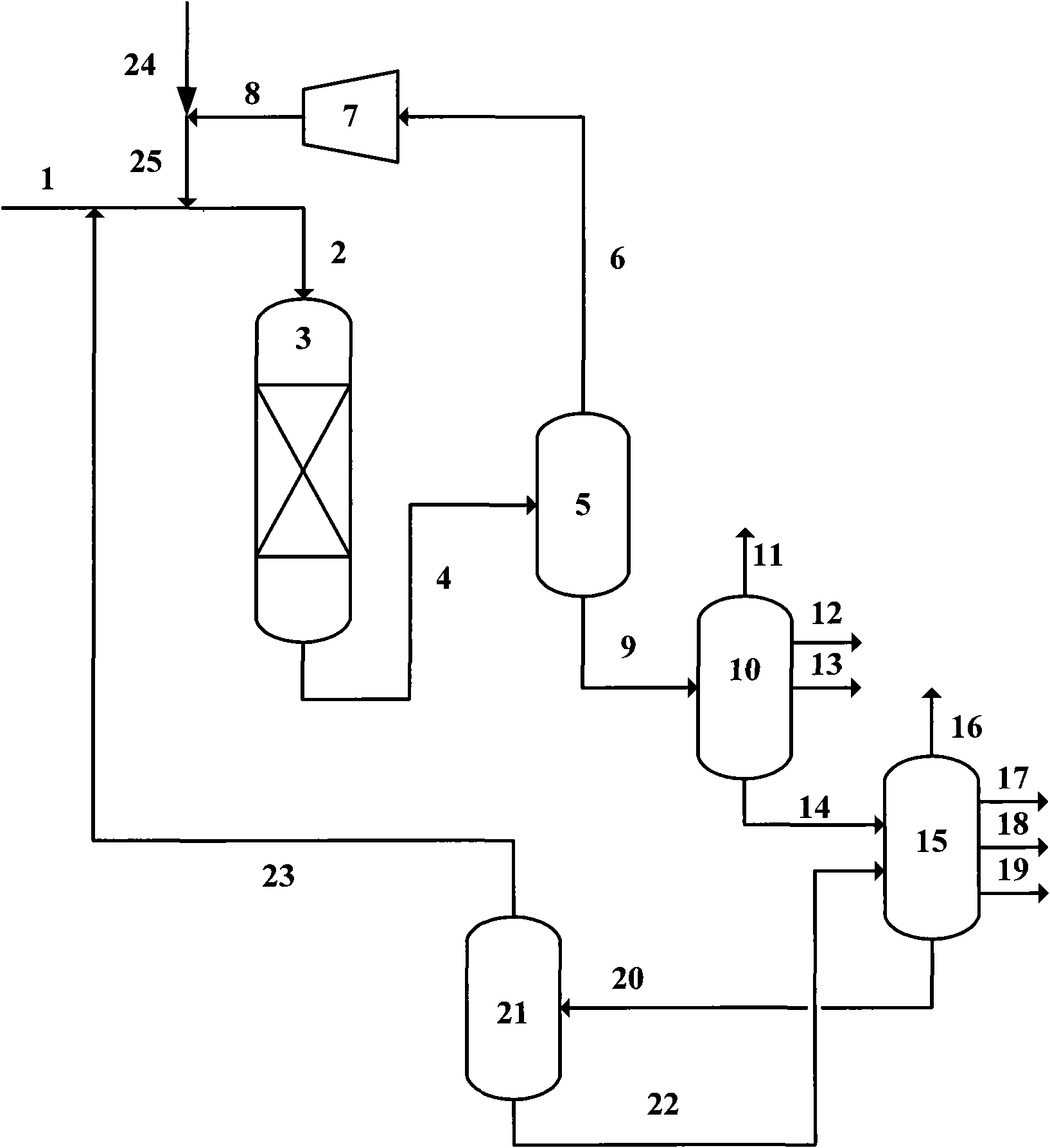

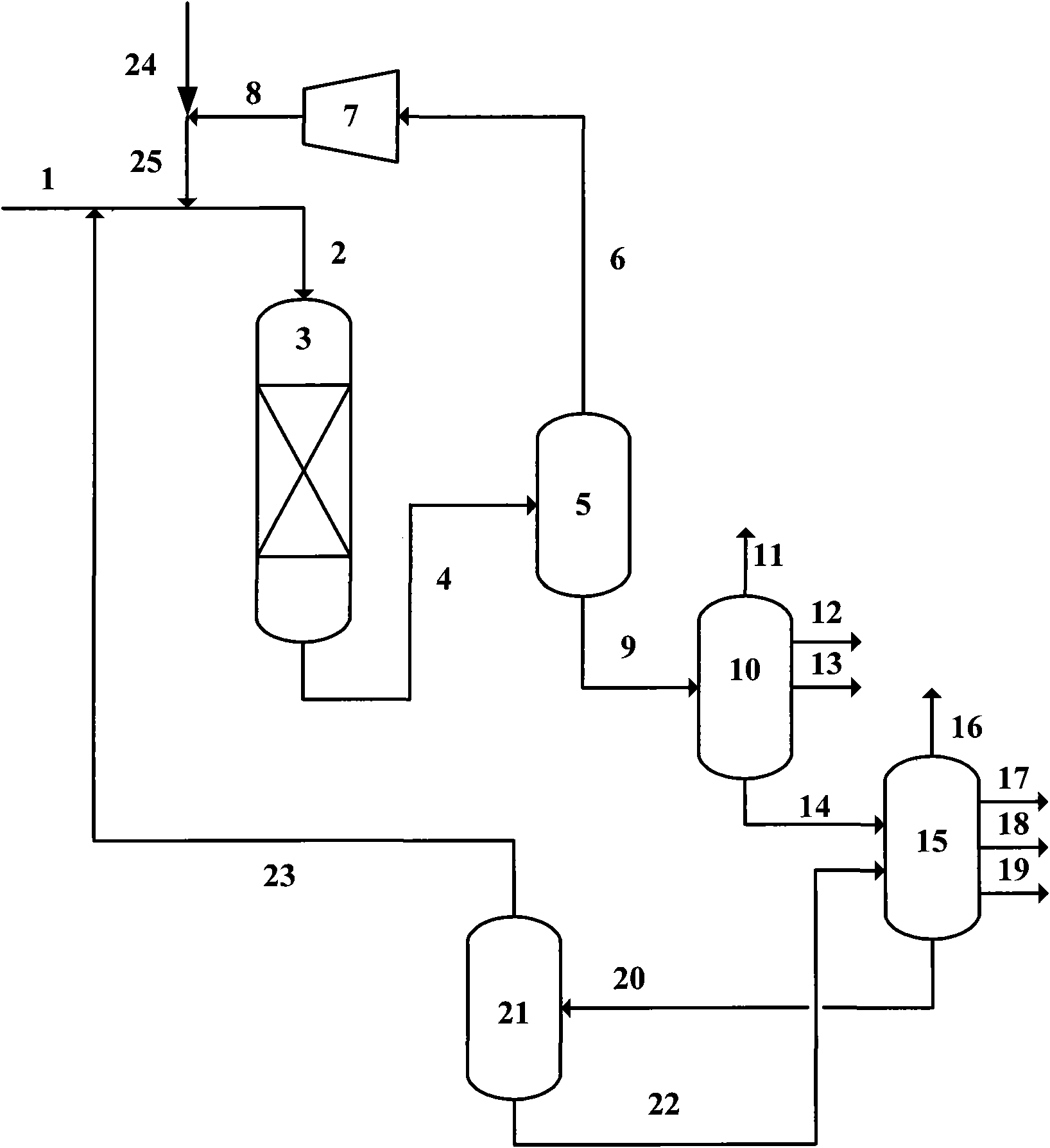

[0027]The residue raw material A is mixed with the extracted oil extracted from catalytic cracking heavy oil aromatics, and enters the residue hydrogenation unit together with hydrogen. The reaction is carried out under the action of the residual oil hydrogenation catalyst, and the hydrogenated oil enters the hot high-pressure separator to be separated into a gas phase stream and a liquid phase stream, wherein the gas phase stream is recycled after being purified and boosted. The liquid phase stream is fractionated at normal pressure to obtain gas, hydrogenated gasoline, hydrogenated diesel oil and hydrogenated residual oil. The hydrogenated residual oil is used as the raw material for catalytic cracking, and the reaction is carried out in the presence of a catalytic conversion catalyst, and the reaction products are separated to obtain dry gas and liquefied gas. , FCC gasoline, FCC diesel and FCC heavy oil. The obtained catalytic cracking heavy oil accounts for 30% by weight ...

Embodiment 2

[0029] In this embodiment, residual oil B is used as the raw material, and the process flow is the same as that in Embodiment 1. The operating conditions and product distribution are shown in Table 2.

[0030] As can be seen from Table 2, both Example 1 and Example 2 have achieved relatively high liquid yields (liquefied gas+gasoline+diesel), which are 81.76% and 86.34% respectively. Propylene yields reached 3.91% and 4.90%, respectively. The invention organically combines processes such as hydrogenation treatment, catalytic cracking, aromatics extraction, etc., and produces propylene and light fuel oil from inferior raw materials to the maximum extent, thereby realizing efficient utilization of petroleum resources.

[0031] Table 1

[0032] Raw oil number

A

B

Density (20℃), kg / m 3

1023.8

970.0

Kinematic viscosity (100℃), mm 2 / Second

1570

481.3

Carbon residue, wt%

20.2

13.95

Nitrogen, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com