Method for producing lightweight fuel oil by coal tar heavy fractioning hydrogenation

A heavy fraction, coal tar technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of short operation cycle, high freezing point of diesel, unsuitable for processing, etc., to improve the yield of light oil , The effect of reducing production costs and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

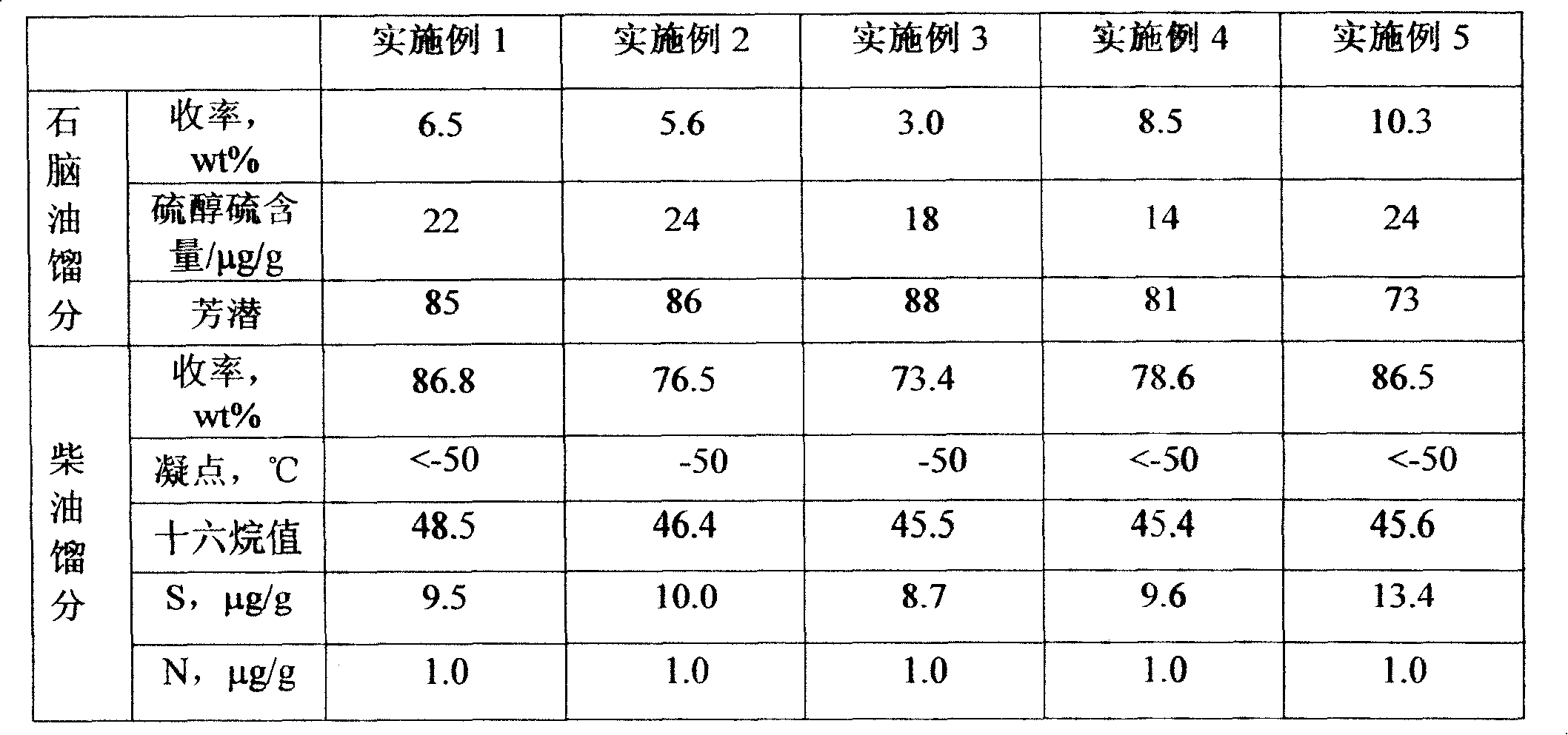

Embodiment 1~5

[0031] The properties of the raw oil used in the examples are shown in Table 1. (wherein wt% is weight percent)

[0032] Table 1 Raw Oil Properties

[0033] Raw oil

1#

2#

Density, g / cm 3

1.10

1.16

Distillation range / ℃

190~420

250~600

Carbon residue, wt%

0.2

2.8

Sulfur content, wt%

0.49

0.52

Nitrogen content, wt%

0.99

1.11

Metal content, μg g -1

33.0

20.0

Oxygen content, wt%

1.3

2.0

Aromatic content, wt%

100.0

100.0

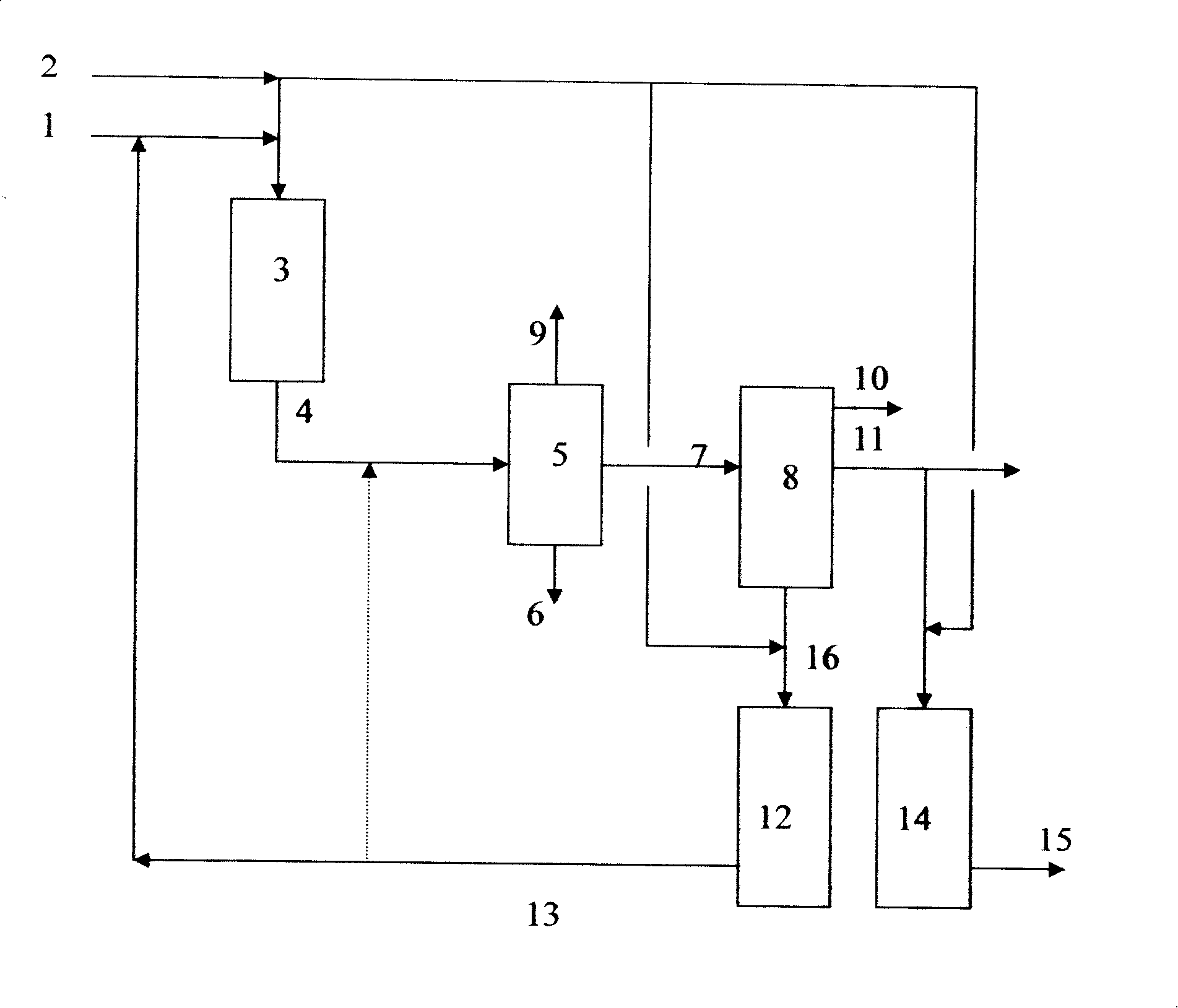

[0034] First, the heavy fraction of coal tar is mixed with hydrogen into the hydrofinishing reactor to obtain hydrofinishing oil for fractionation, and the tail oil obtained enters the hydrocracking reactor, and all the cracked oil is returned to the hydrofining reactor to obtain hydrofining The resulting oil is fractionated, and hydroreforming treatment is selected according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com