Cleaning agent and cleaning process of GGH heat exchange component

A cleaning agent and process technology, applied in the field of chemical cleaning agents and cleaning processes, can solve the problems of poor descaling effect, high chemical cost, long cleaning time, etc., and achieve the effect of fast cleaning, low cost and effective cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use the following cleaning agents:

[0033] Alkaline cleaning solution contains 6%wtNaOH, 1%wtJFC, 1.5%wtHPMA, 0.5%wtl227, 0.5%wtPAA, and the rest of water; acidic cleaning solution contains 4%wtHCl, 0.3%wt XD-16, 1.0%wtJFC, 0.5% wt TH-241, 0.5% wt PASP, and balance water.

[0034] And adopt the following cleaning process:

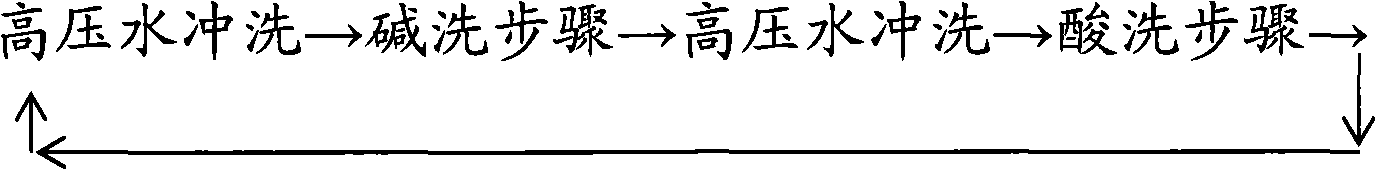

[0035] High-pressure water washing→alkali washing step→high-pressure water washing→acid washing step.

[0036] The alkali washing step is static soaking at 75°C for 6.5 hours; the pickling step is static soaking at 55°C for 6.5 hours.

[0037] Completely cleared an area of 0.1m 2, The GGH heat exchange components with a thickness of 7mm are fouled, and a total of 500mL of alkaline cleaning solution and acid cleaning solution are consumed. The entire cleaning process takes about 13 hours in total.

Embodiment 2

[0039] Use the following cleaning agents:

[0040] Alkaline cleaning solution contains 2%wtNaOH, 1.5%wt fast penetrant T, 1.5%wtEDTA, 0.5%wt 1631, 0.5%wtPASP, and the rest of water; acidic cleaning solution contains 3%wtHCl, 0.3%wtBTA, 1.0% wtJFC, 0.5% wt TH-3100, 0.5% wt PESA, and the balance water.

[0041] And adopt the following cleaning process:

[0042] High-pressure water washing→alkali washing step→high-pressure water washing→acid washing step.

[0043] The alkaline washing step is statically soaked at 70°C for 5 hours; the pickling step is statically soaked at 50°C for 5 hours.

[0044] Completely cleared an area of 0.1m 2 , The GGH heat exchange components with a thickness of 6mm are fouled, and a total of 500mL of alkaline cleaning solution and acid cleaning solution are consumed. The entire cleaning process takes about 10 hours in total.

Embodiment 3

[0046] Use the following cleaning agents:

[0047] Alkaline cleaning solution contains 10%wtNaOH, 0.8%wtJFC, 1.5%wtHPMA, 0.5%wtM-9, 0.5%wtPAAS, and the rest of water; acidic cleaning solution contains 5%wtHCl, 0.3%wtMBT, 1.0%wtJFC, 0.5 %wt POCA, 0.5%wt HPAA, and balance water.

[0048] And adopt the following cleaning process:

[0049] High-pressure water washing→alkali washing step→high-pressure water washing→acid washing step.

[0050] The alkali washing step is statically soaked at 80°C for 8 hours; the pickling step is statically soaked at 60°C for 8 hours.

[0051] Completely cleared an area of 0.1m 2 , The GGH heat exchange components with a thickness of 7mm are scaled, and a total of 500mL of alkaline cleaning solution and acid cleaning solution are consumed. The entire cleaning process takes about 16 hours in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com