Patents

Literature

30results about How to "With anti-blocking function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

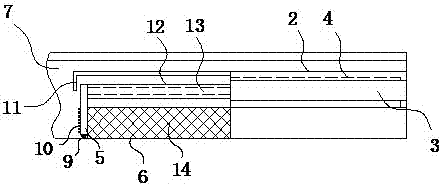

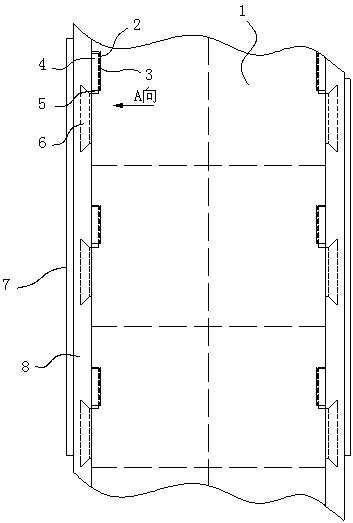

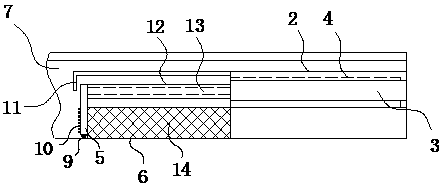

Sintered water permeable brick and preparation method thereof

ActiveCN106087631AImprove water permeabilityLittle tortuousnessSingle unit pavingsPaving detailsBiomass fuelsSurface layer

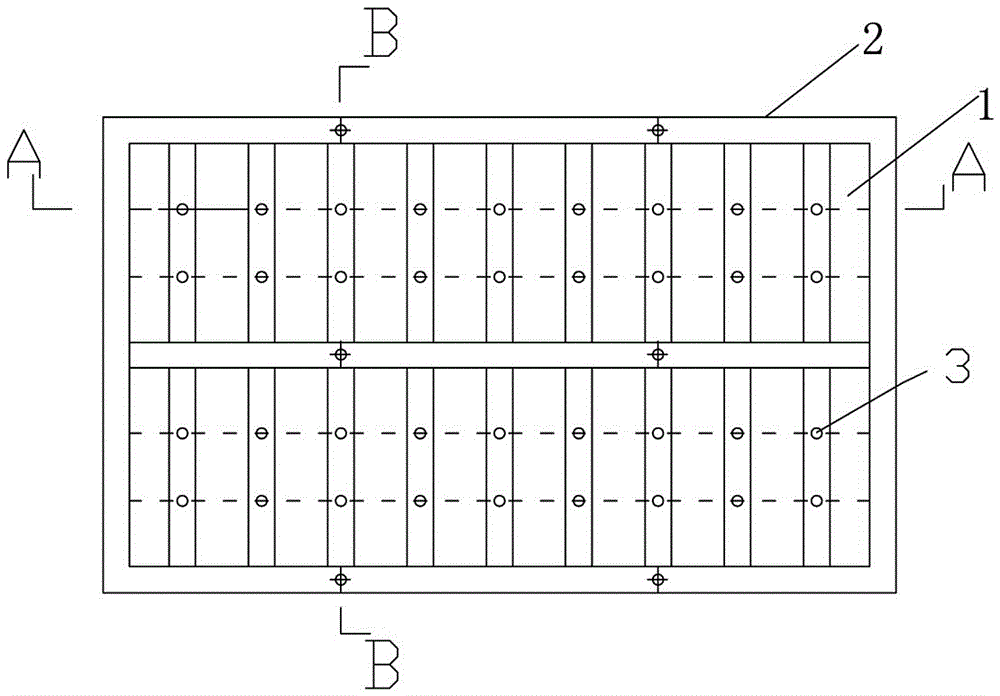

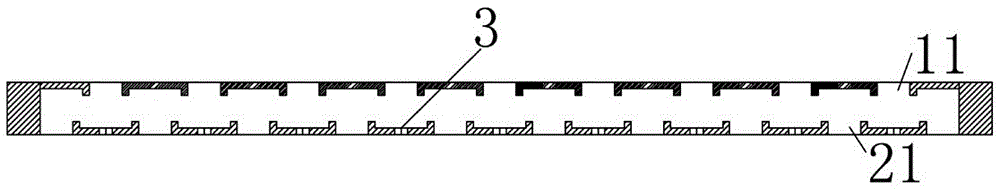

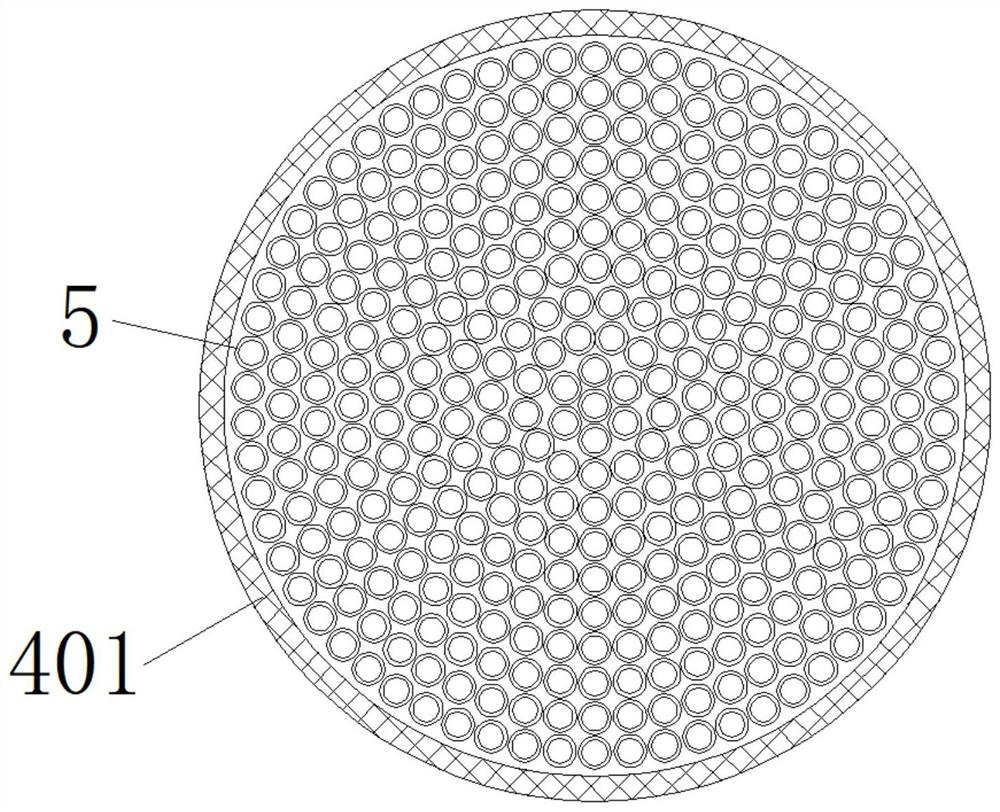

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

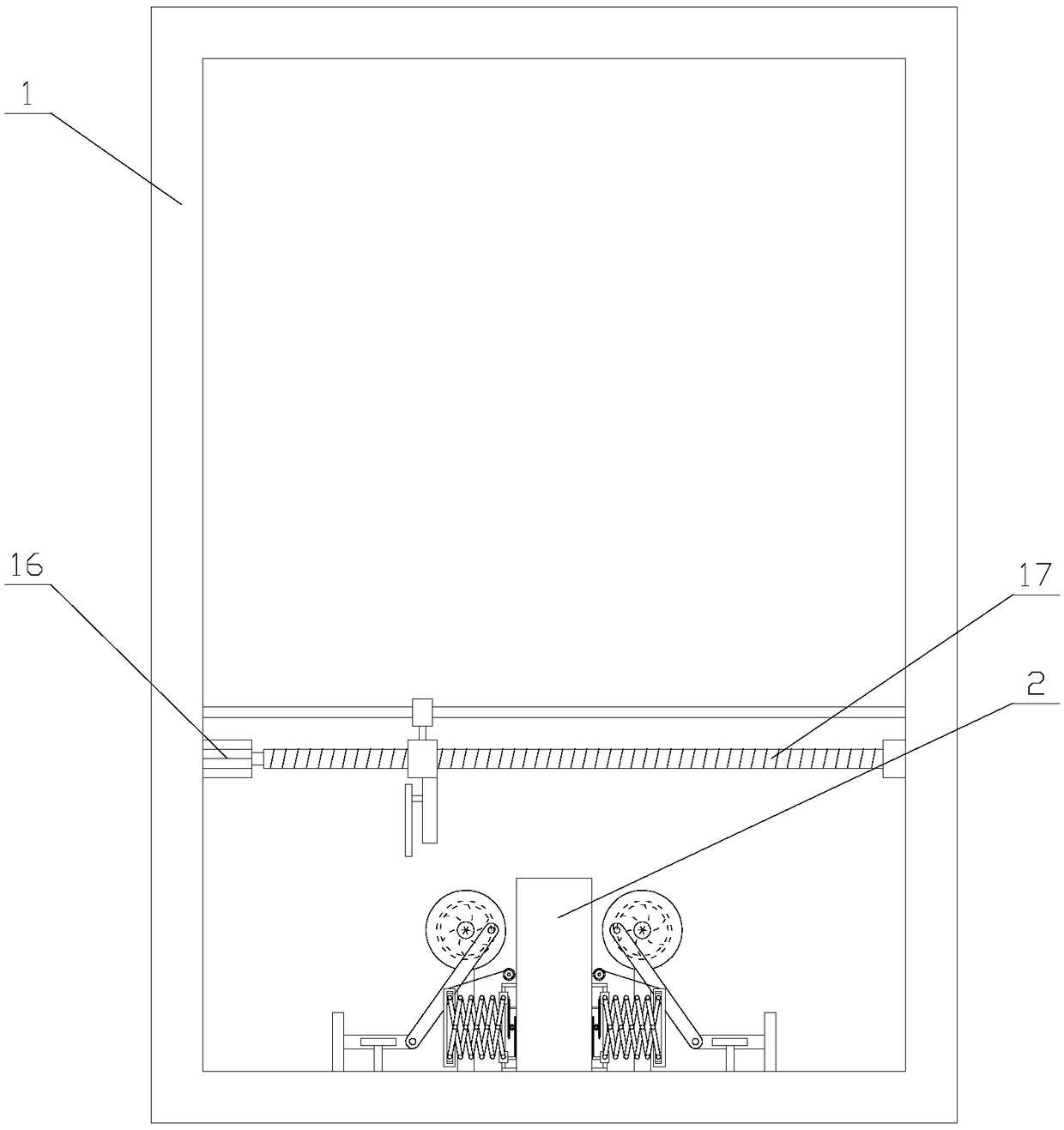

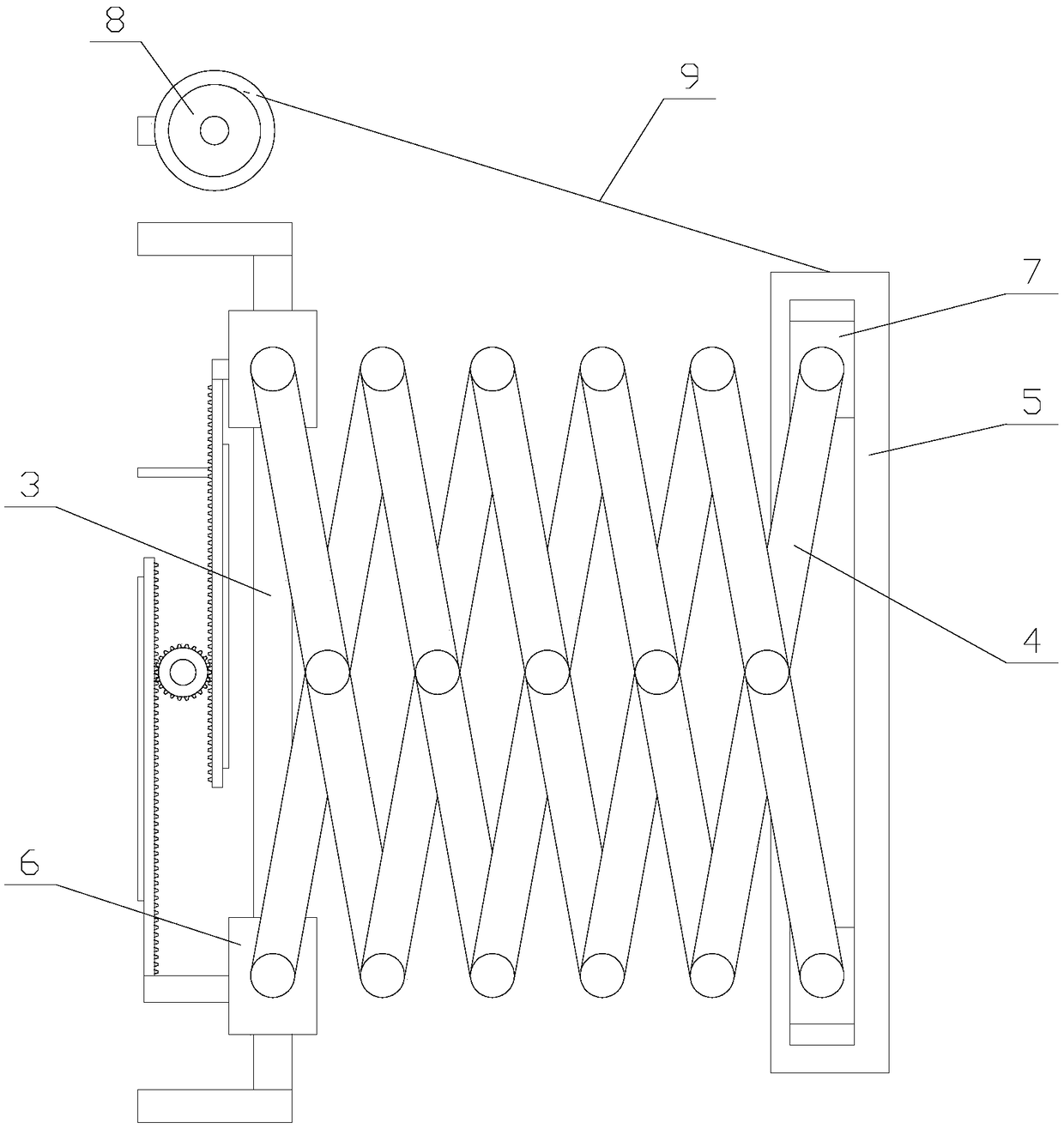

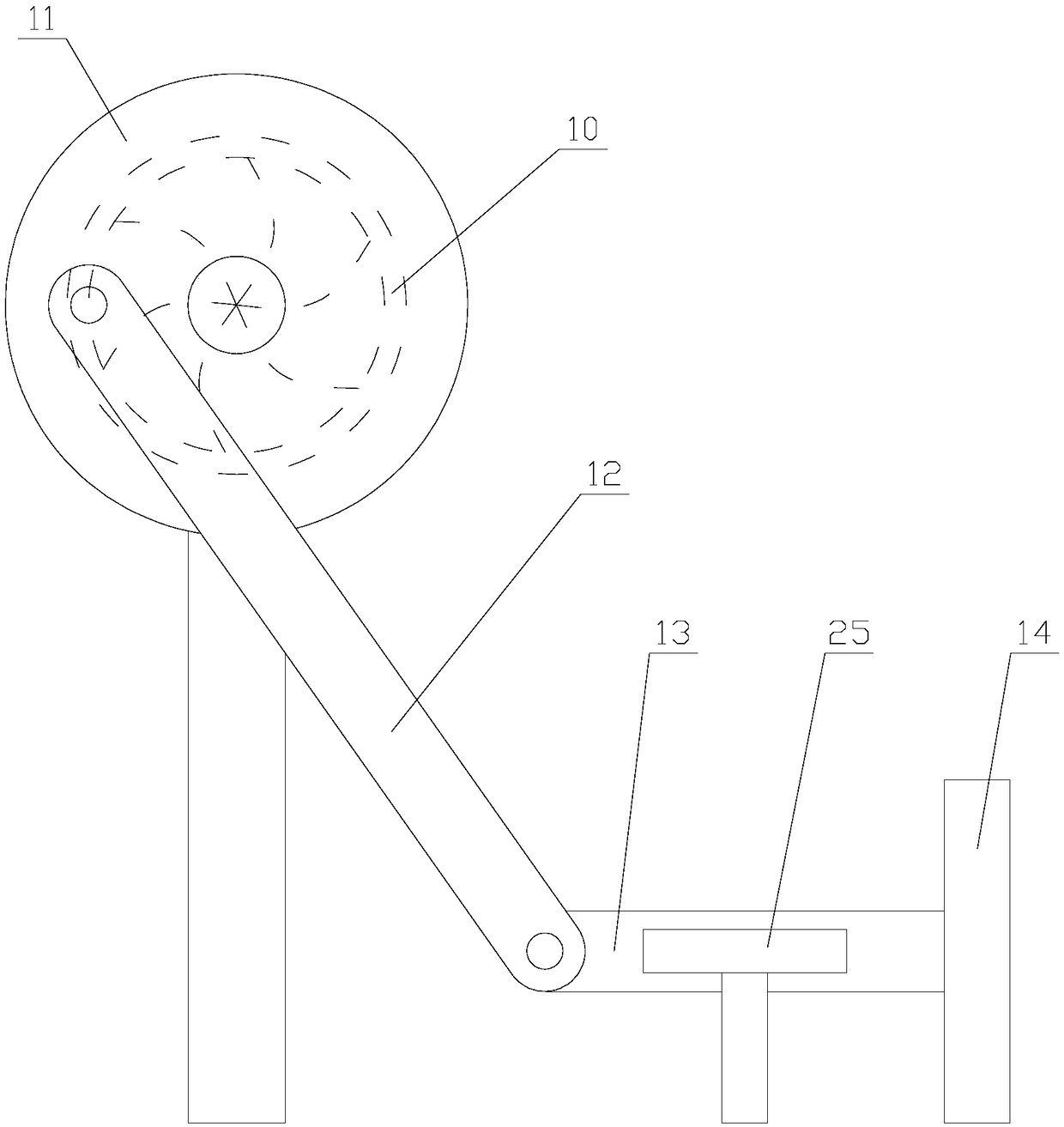

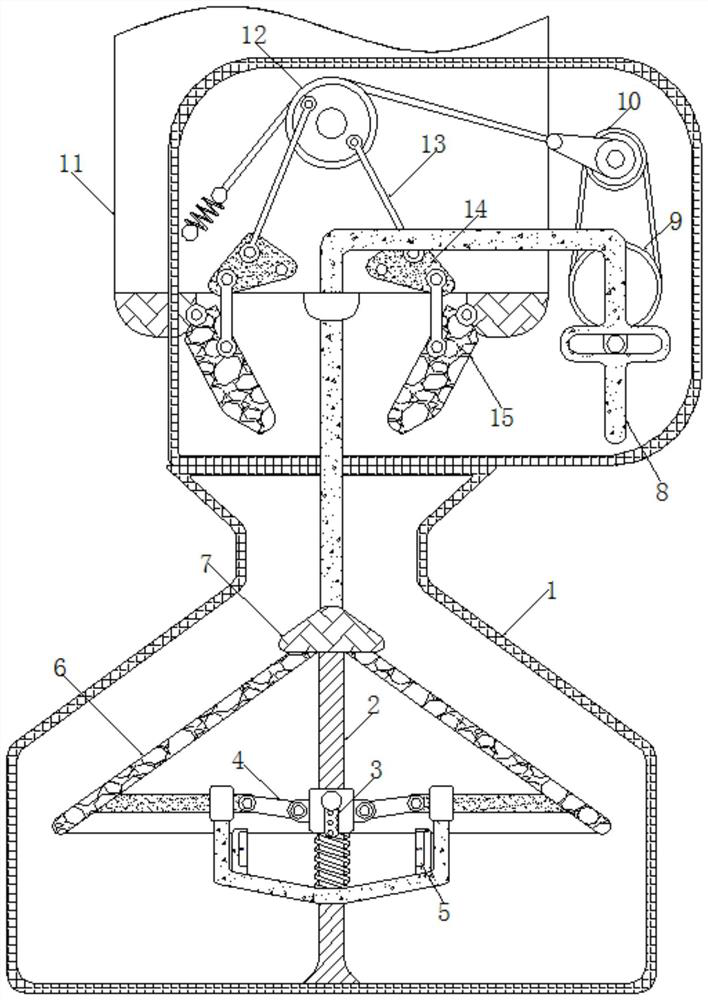

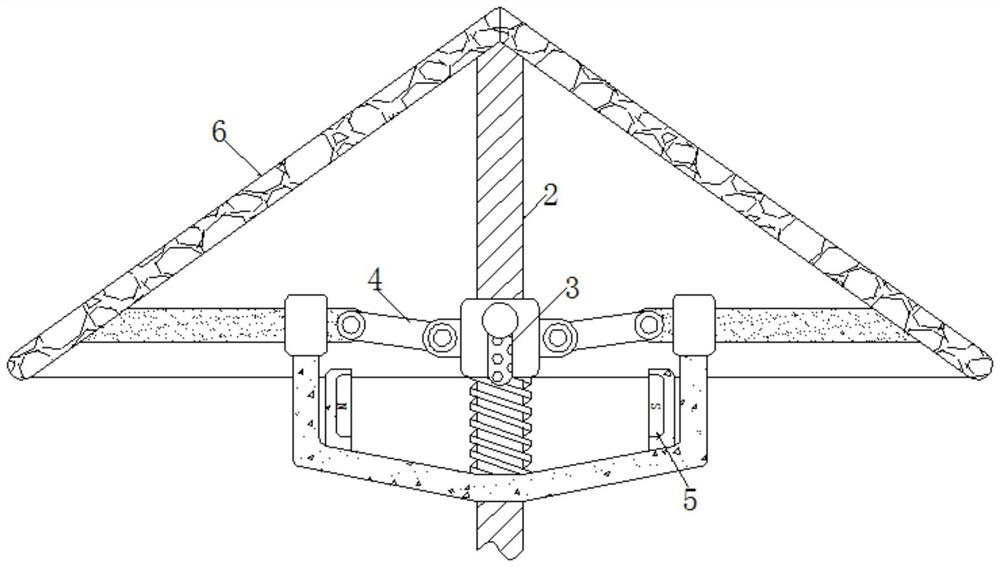

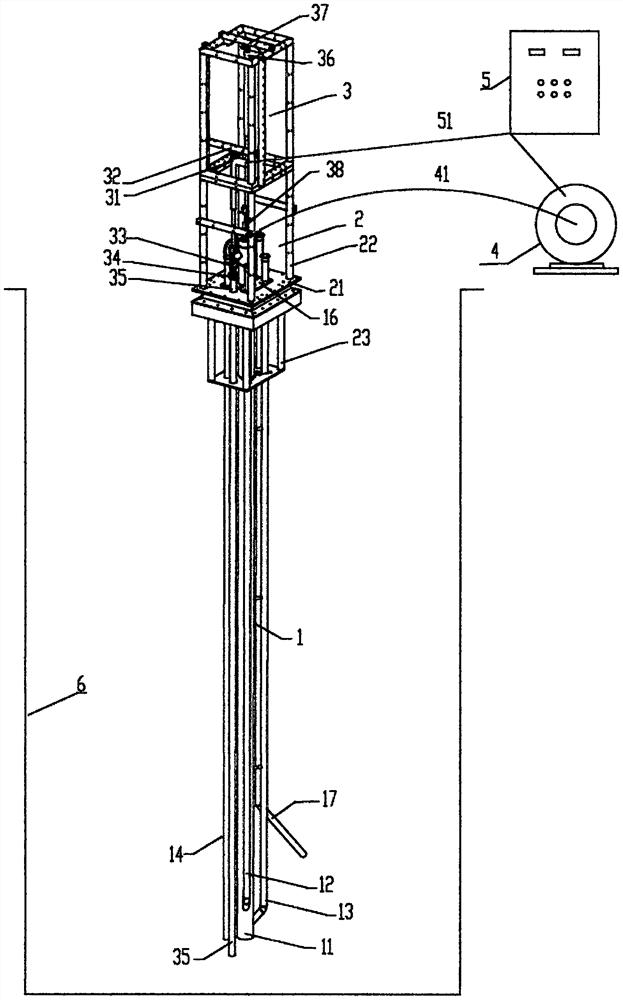

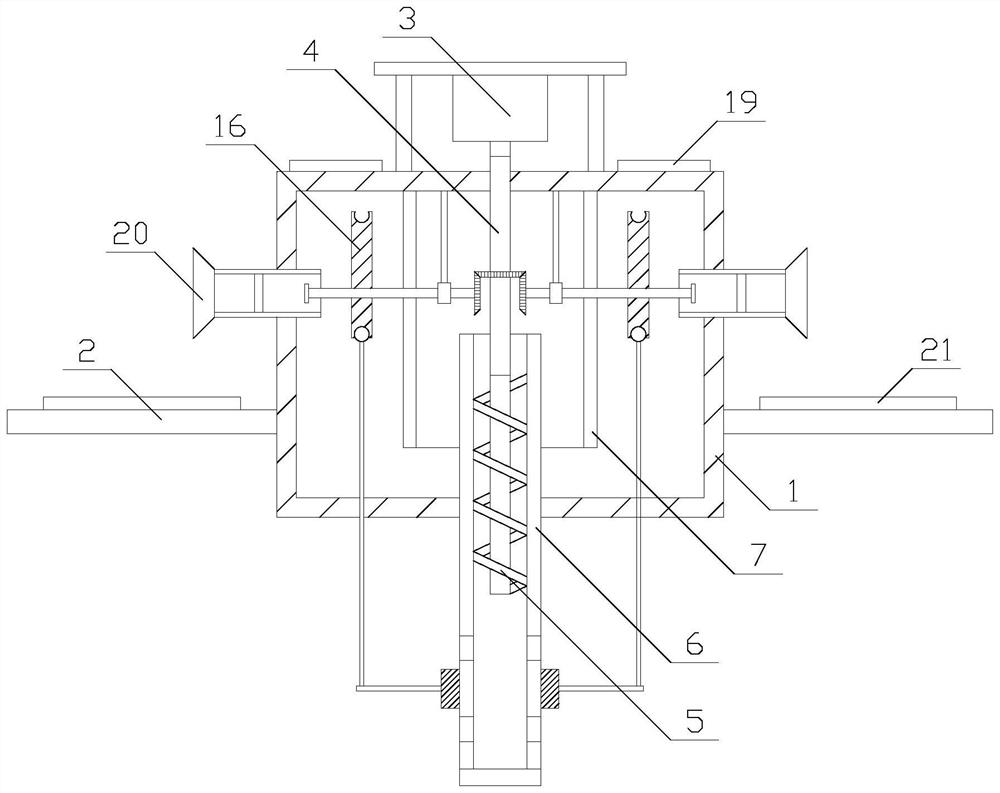

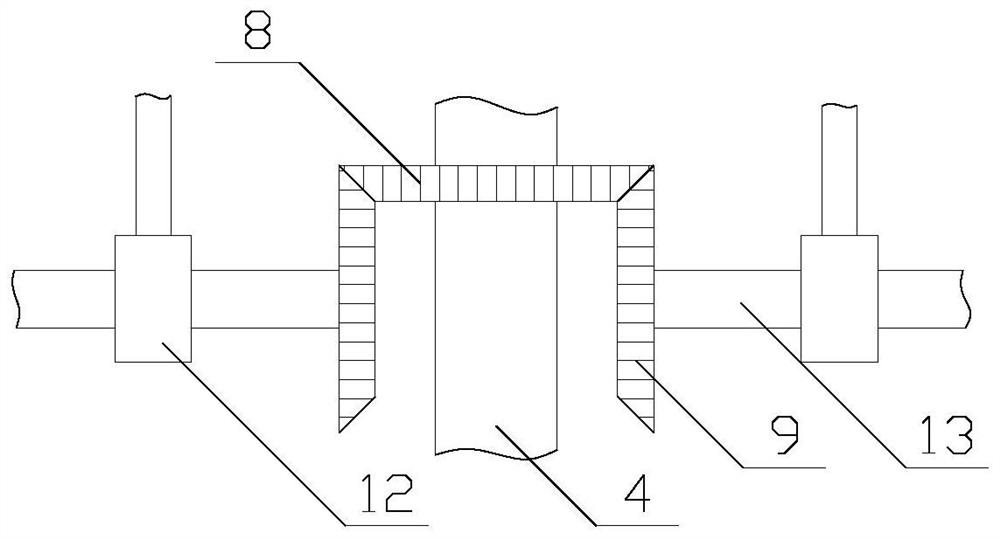

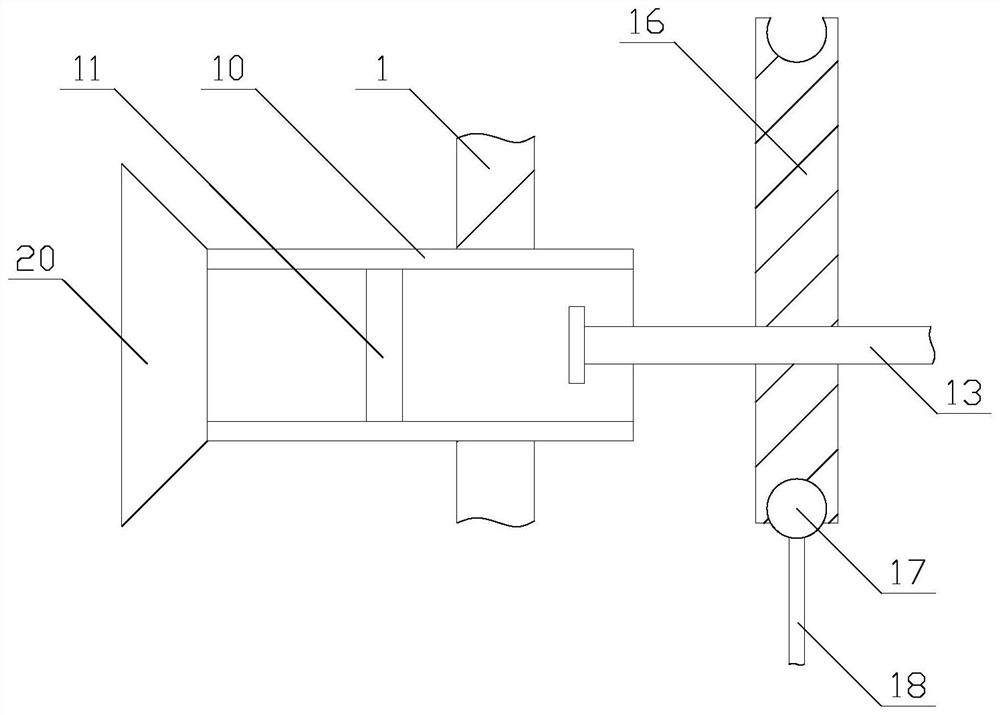

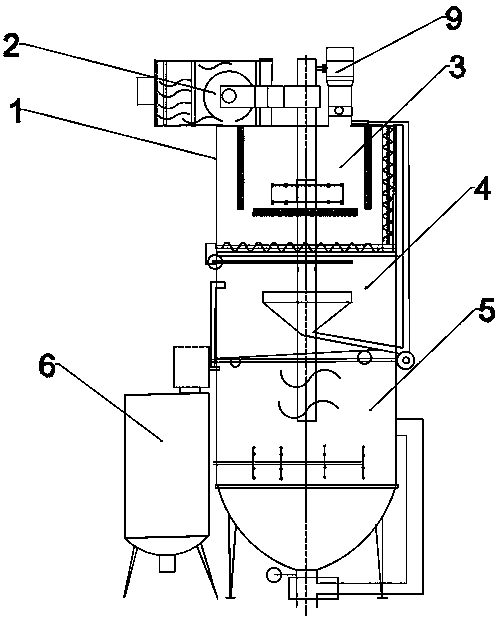

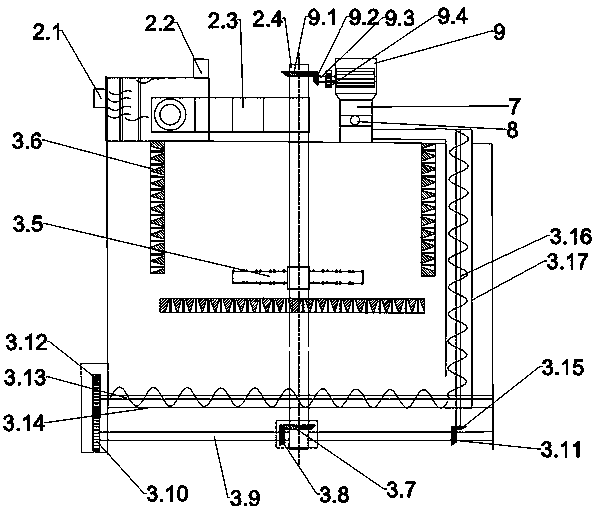

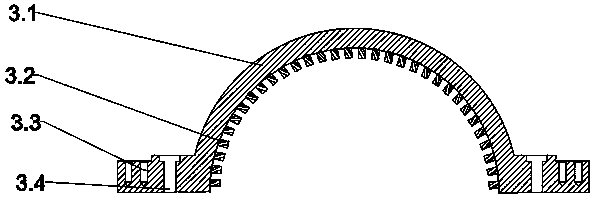

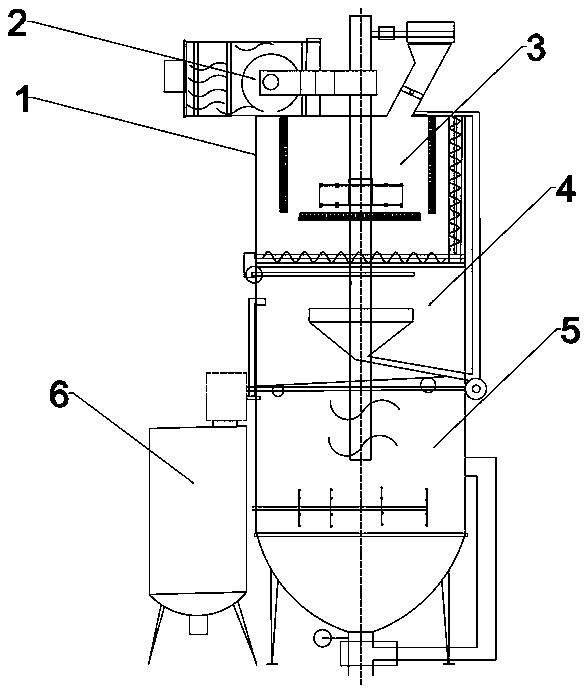

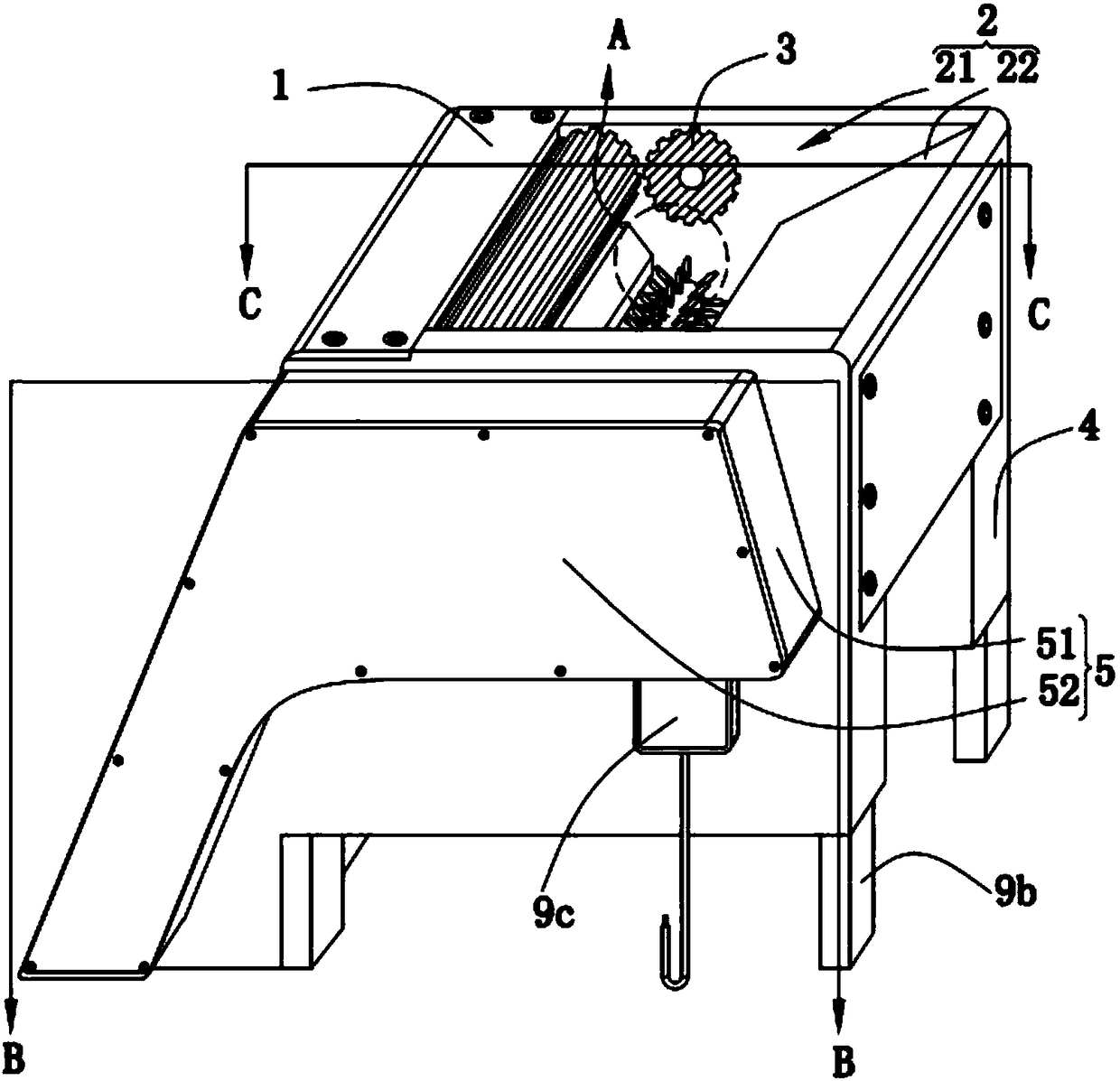

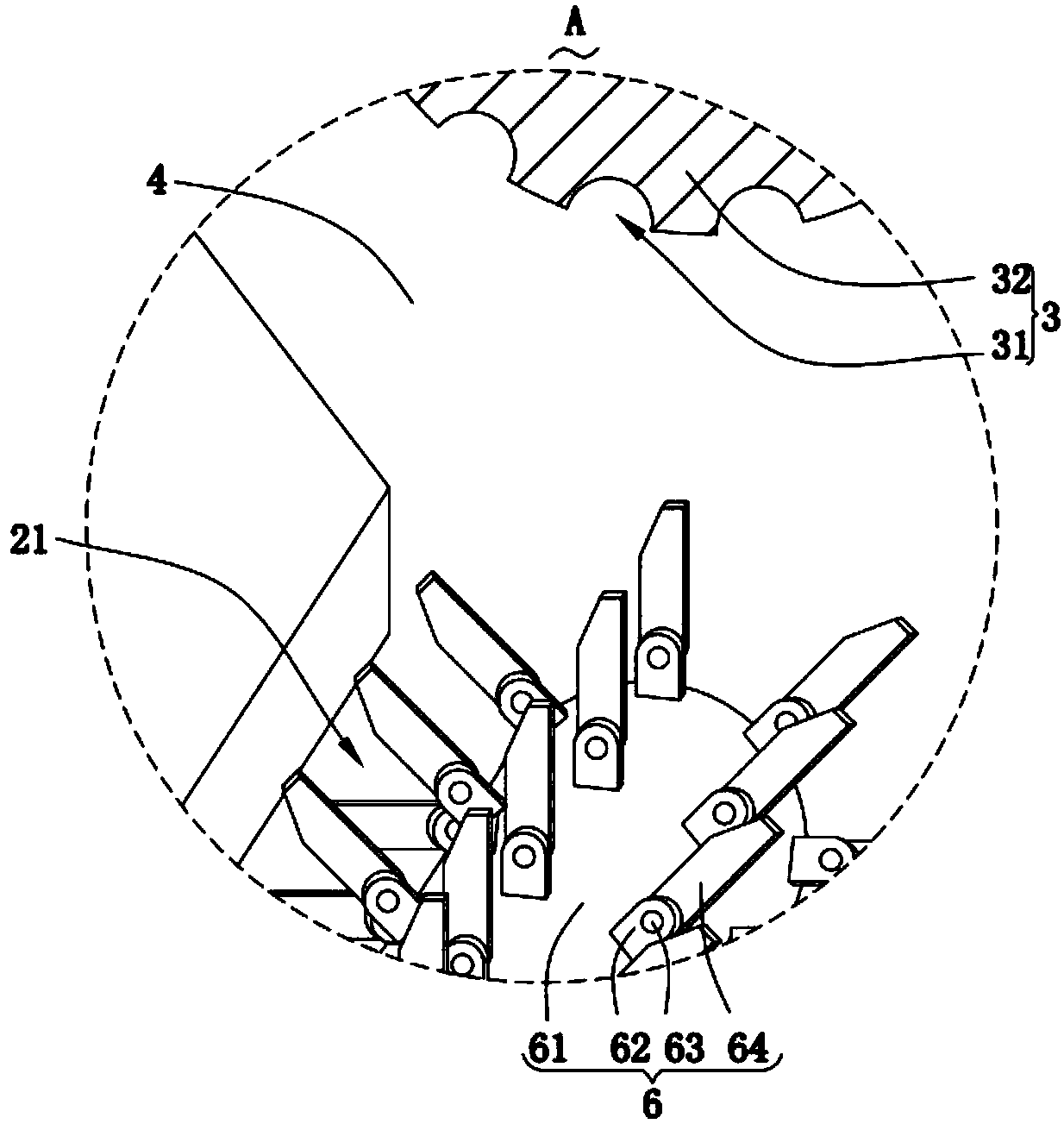

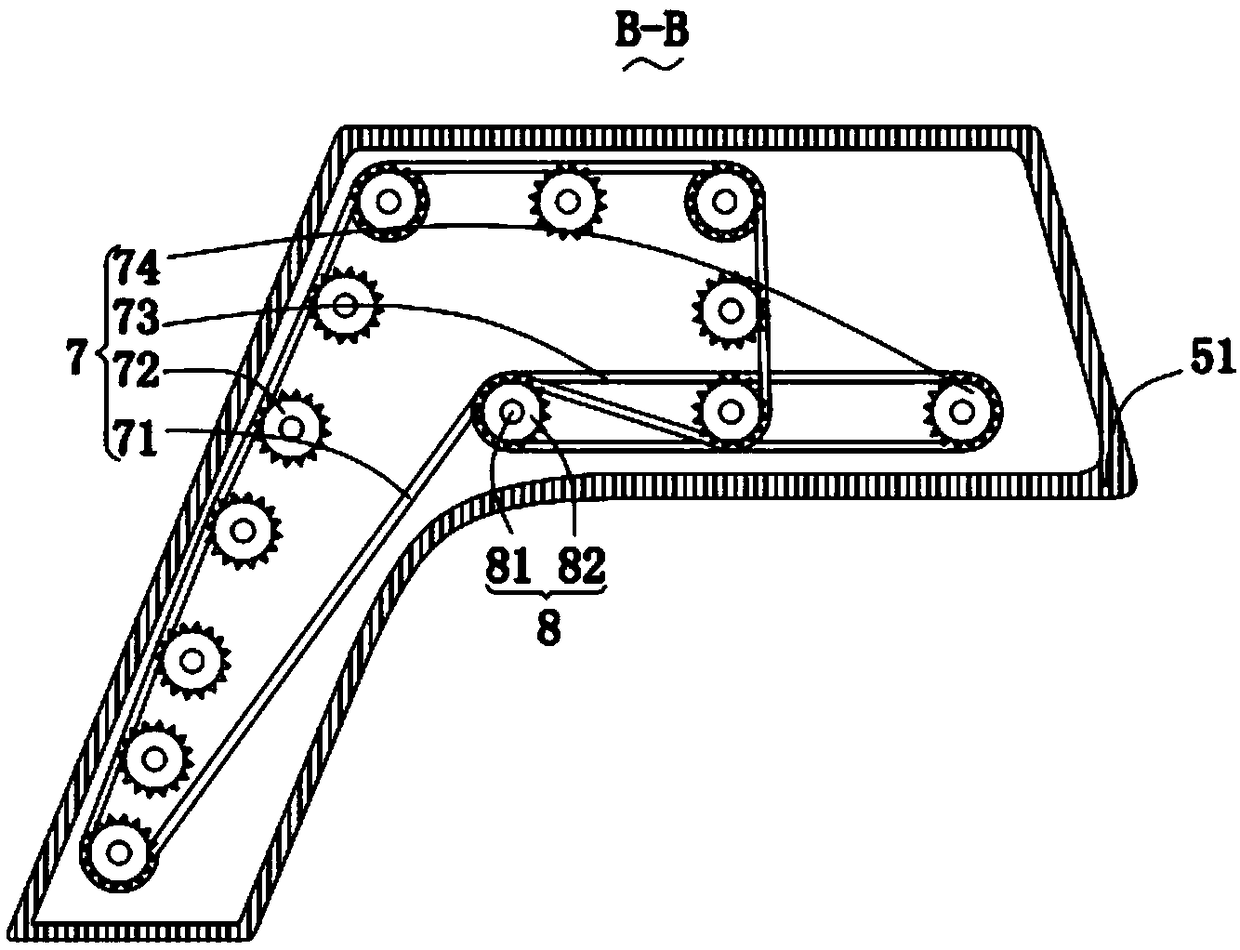

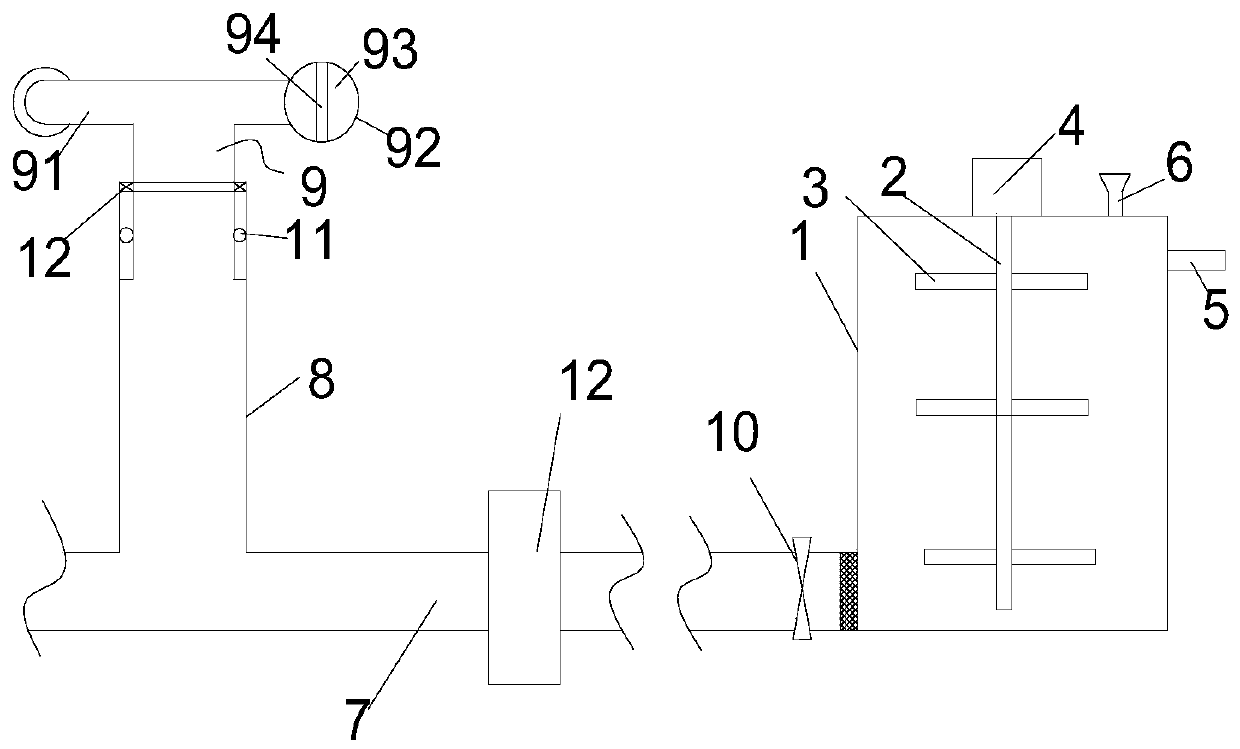

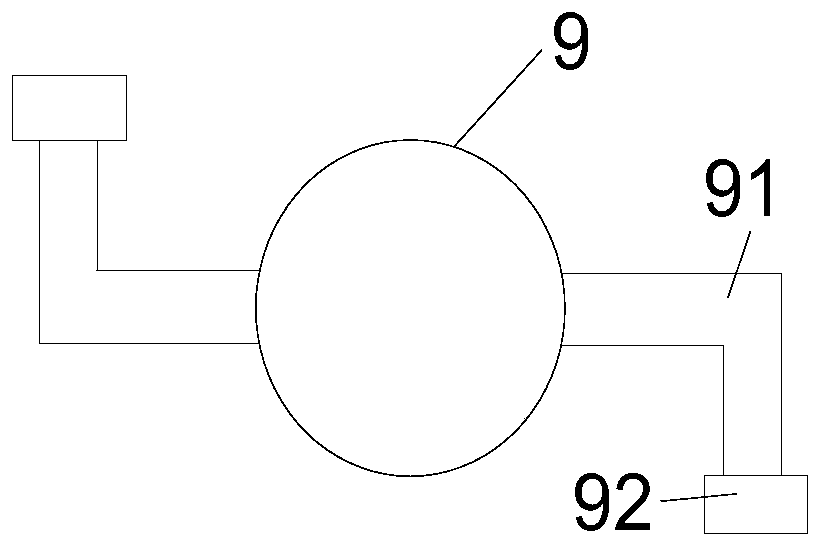

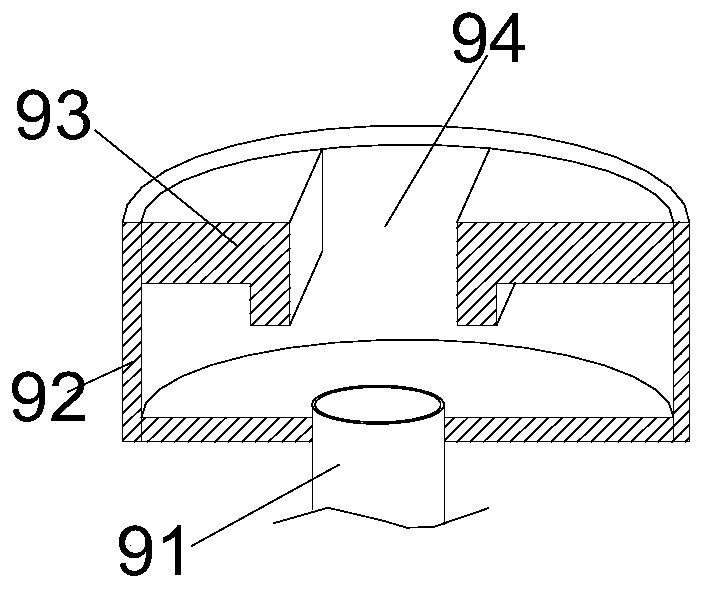

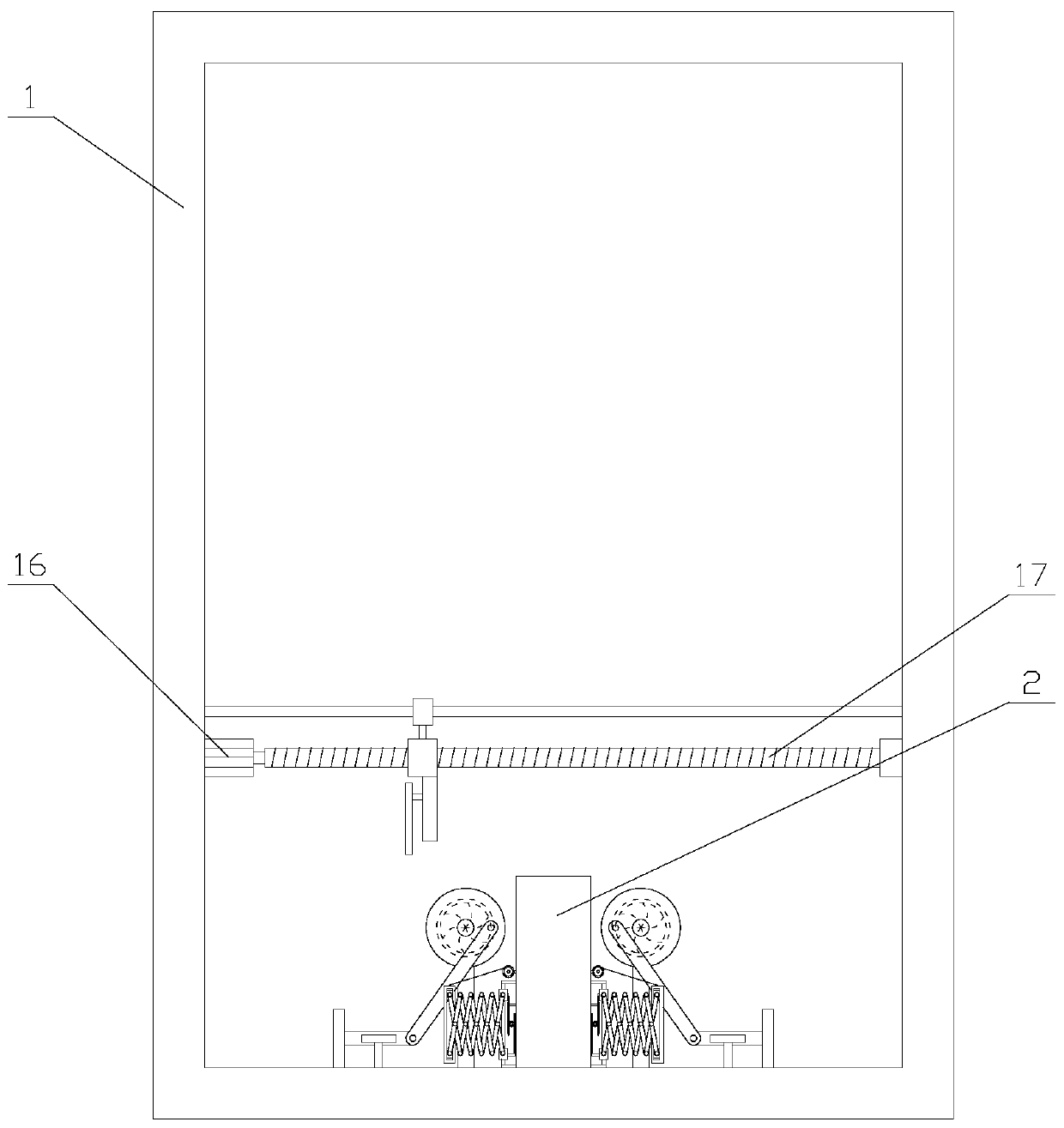

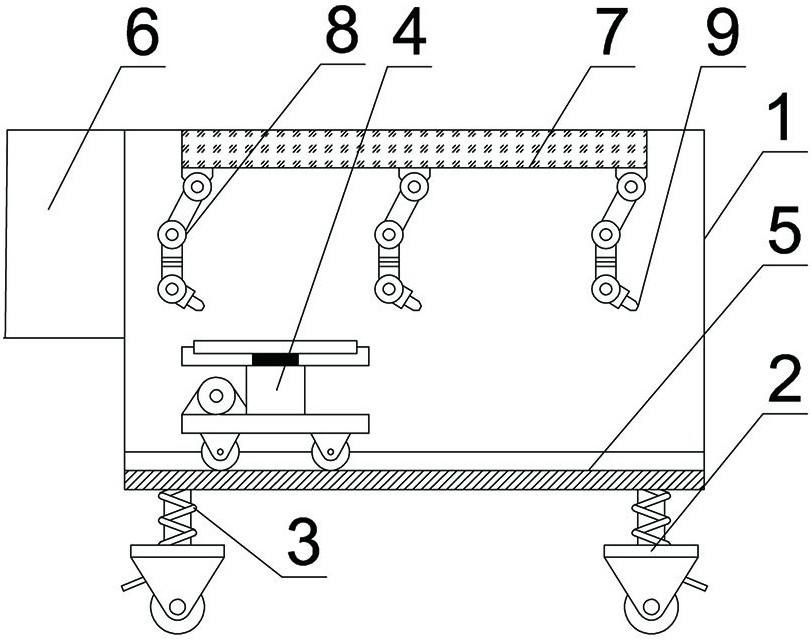

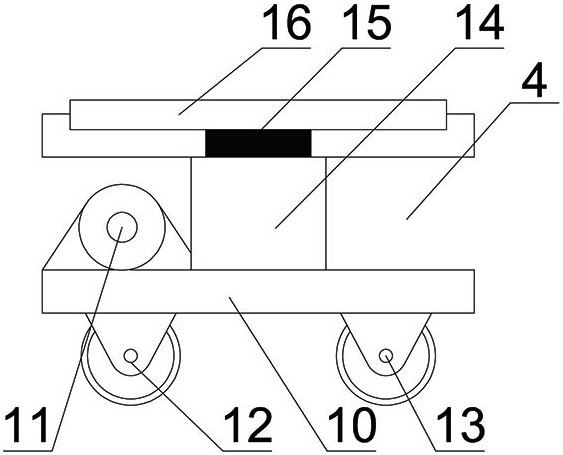

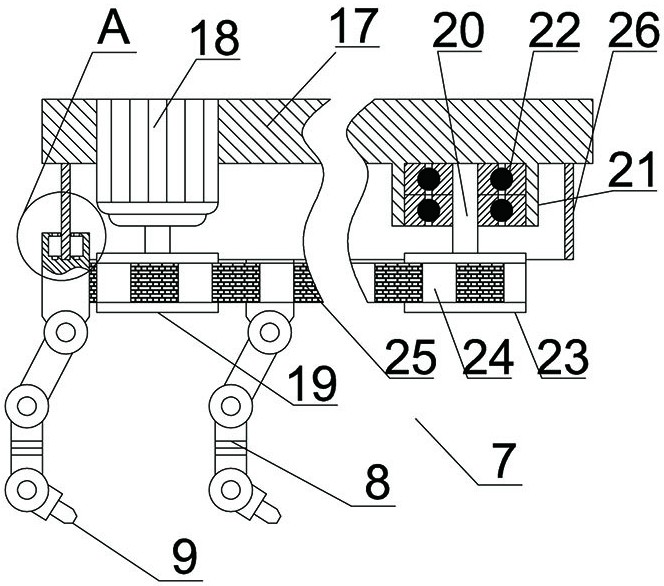

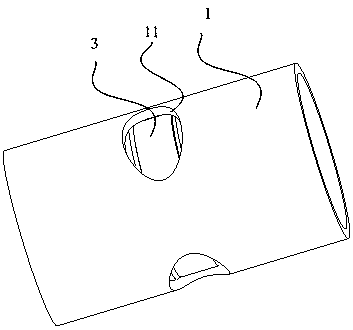

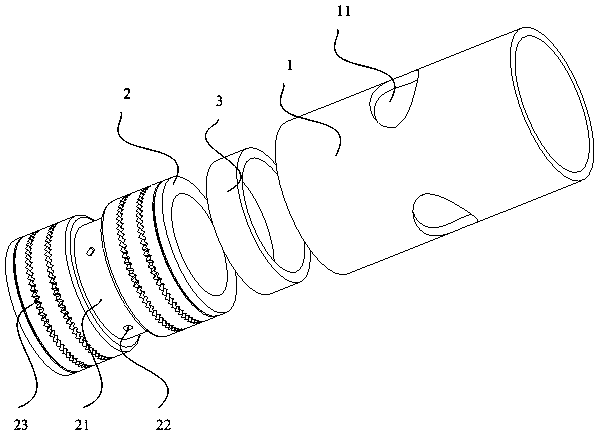

Hydroelectric equipment with anti-blocking function

ActiveCN109026501AWith anti-blocking functionPracticalDrying gas arrangementsHydro energy generationWater turbineEngineering

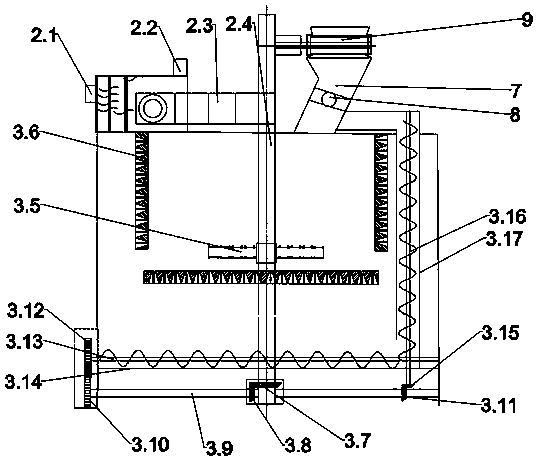

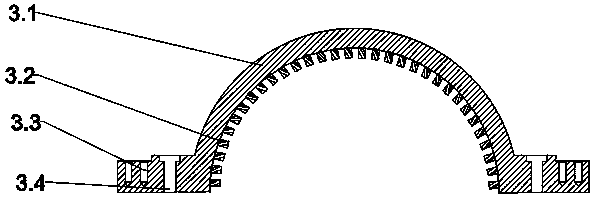

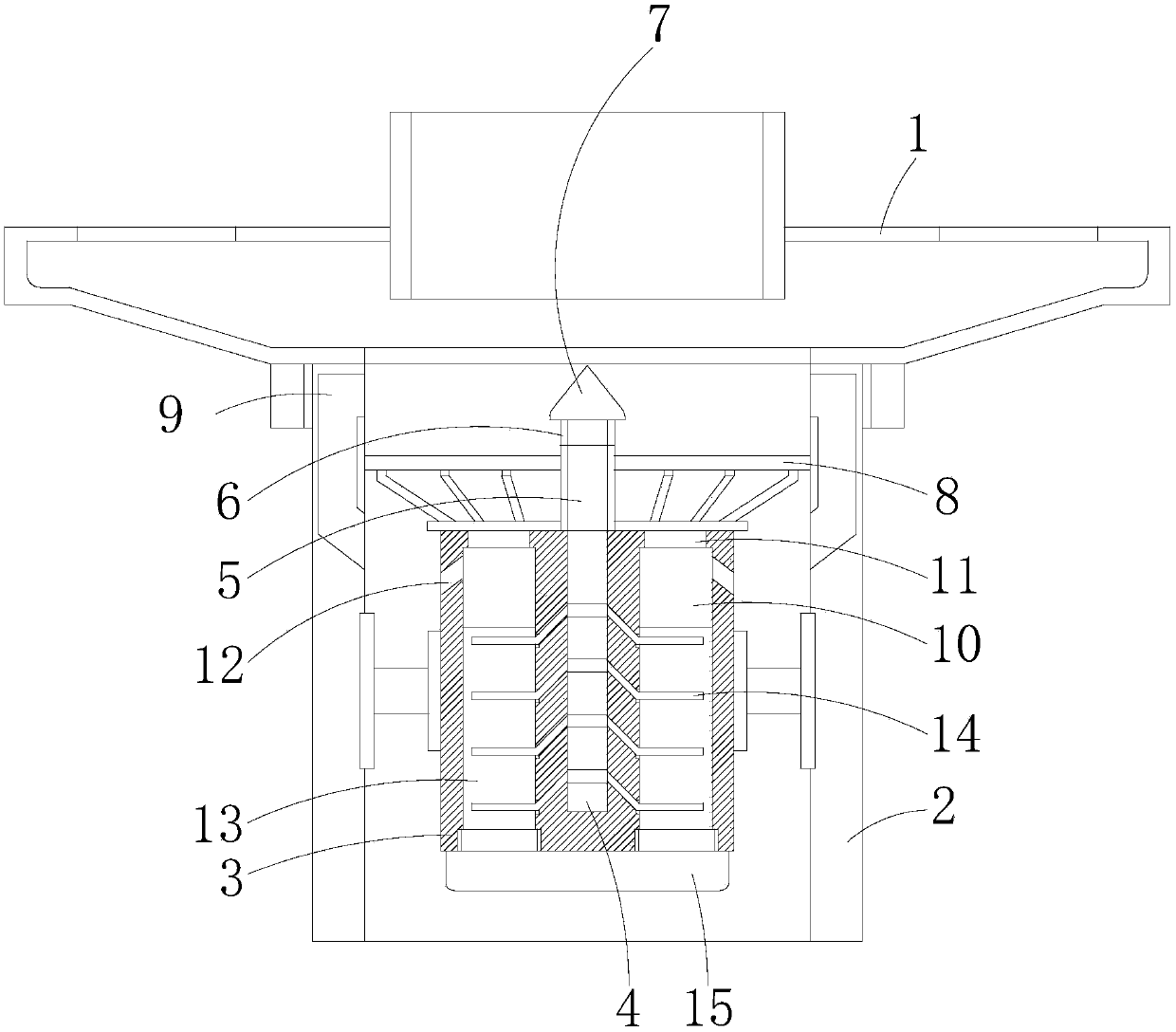

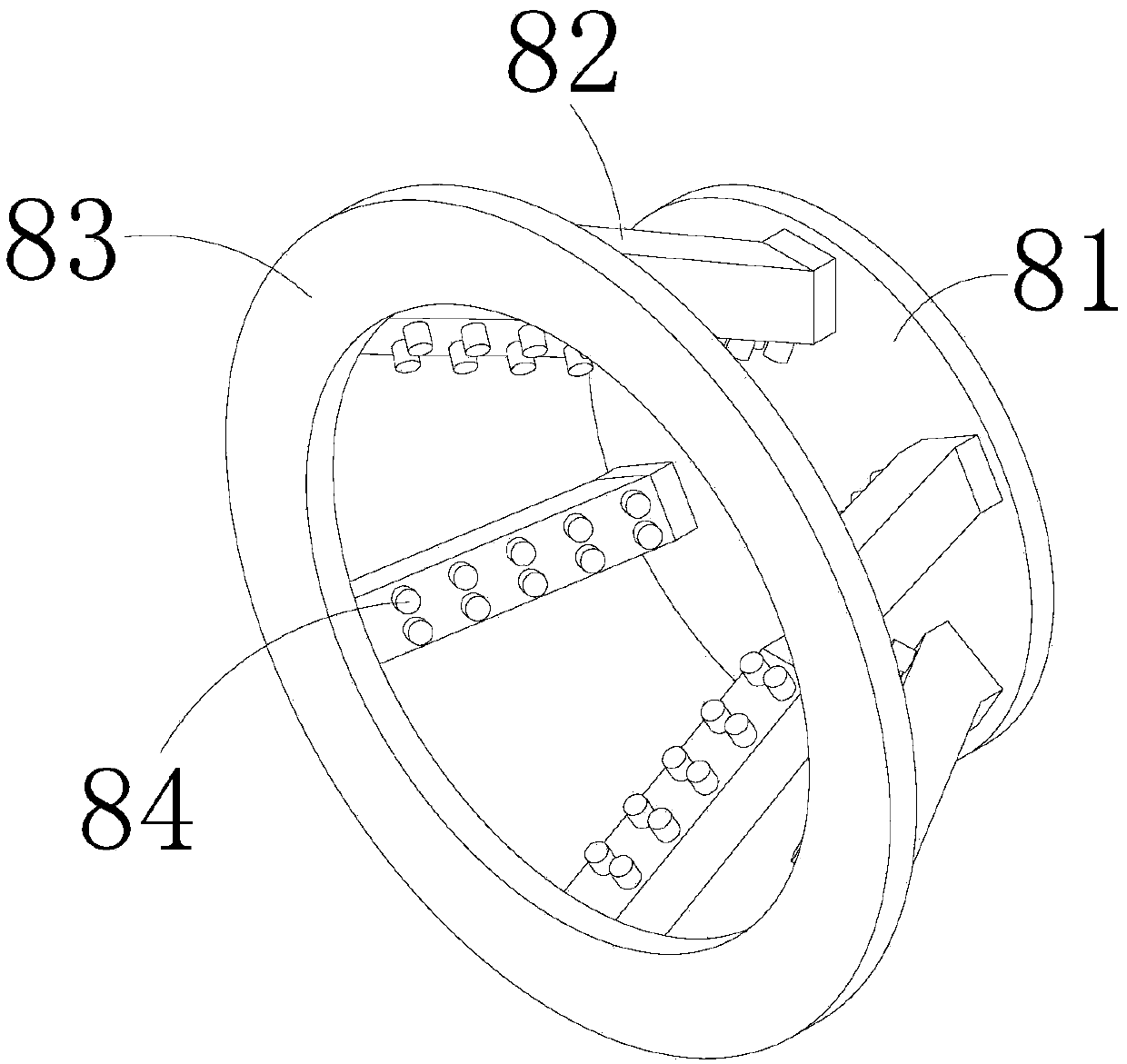

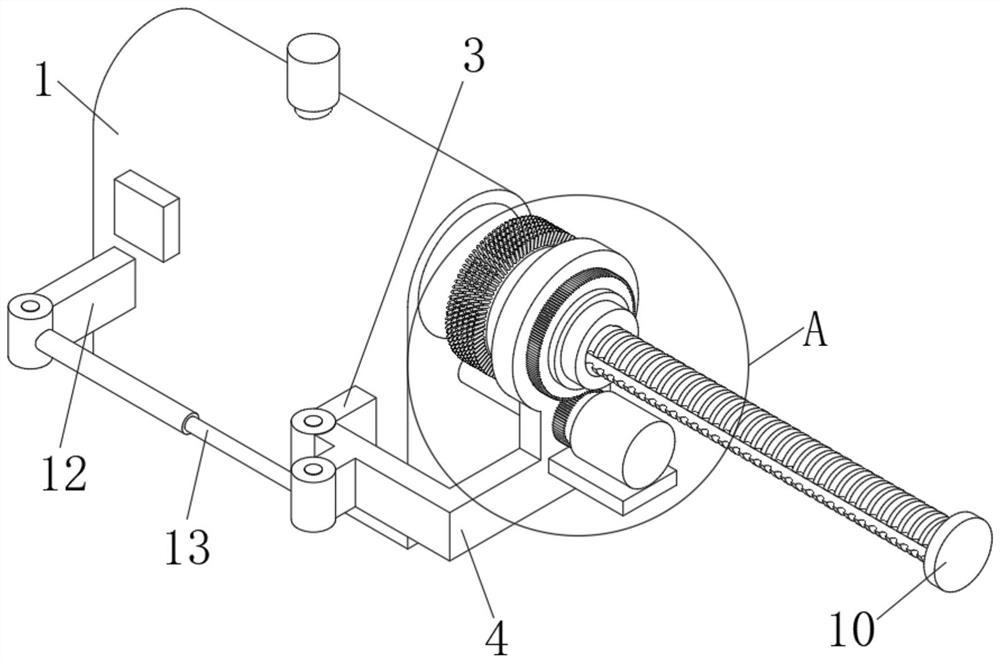

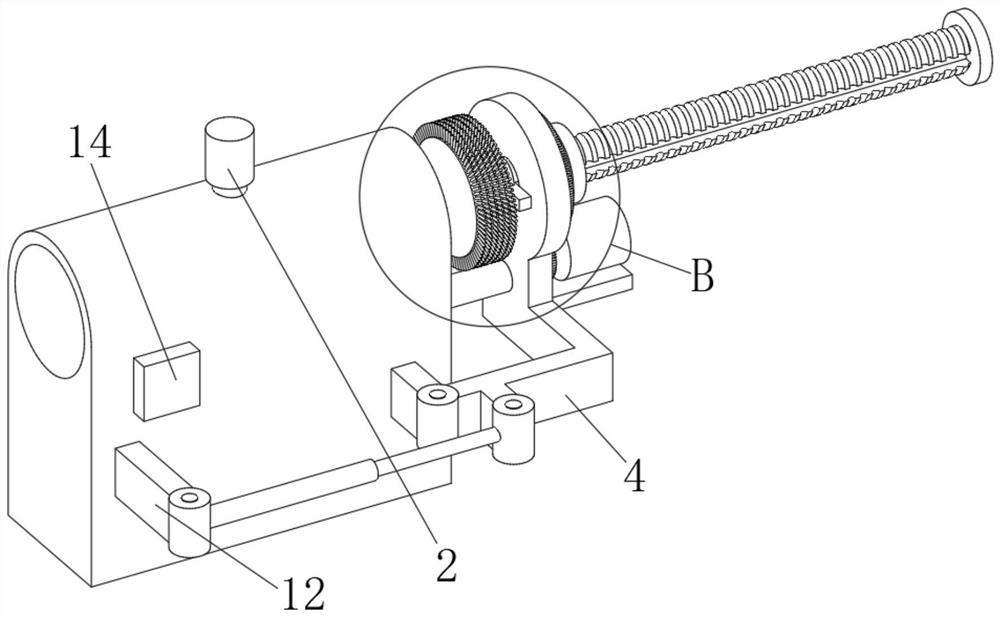

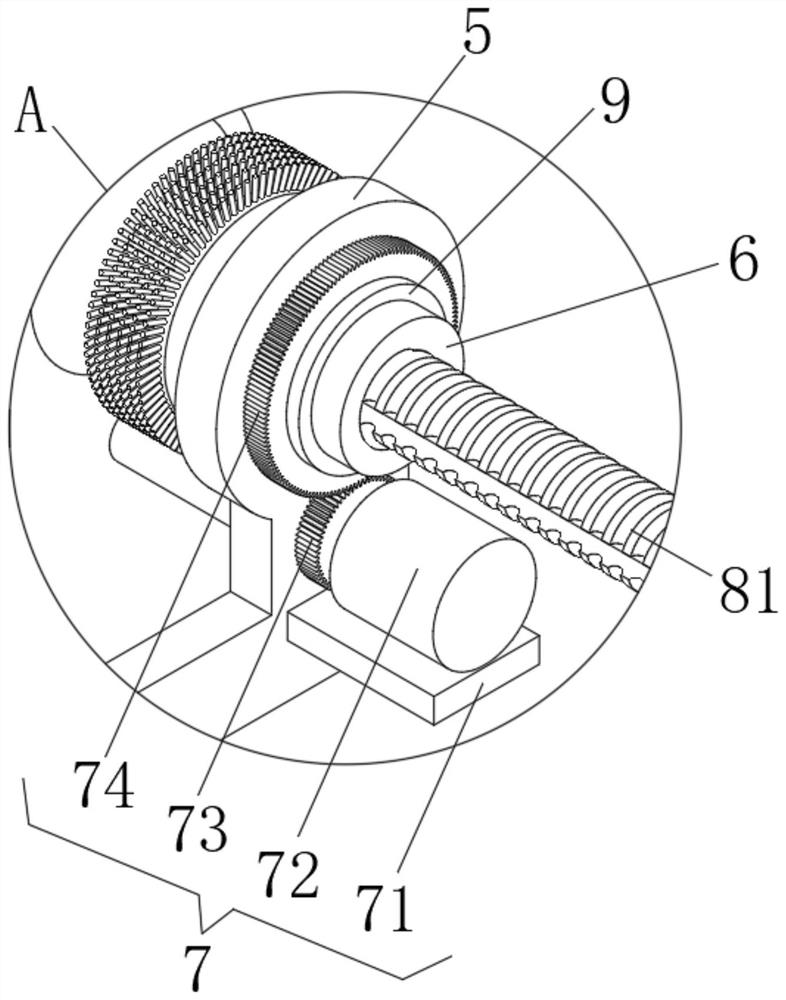

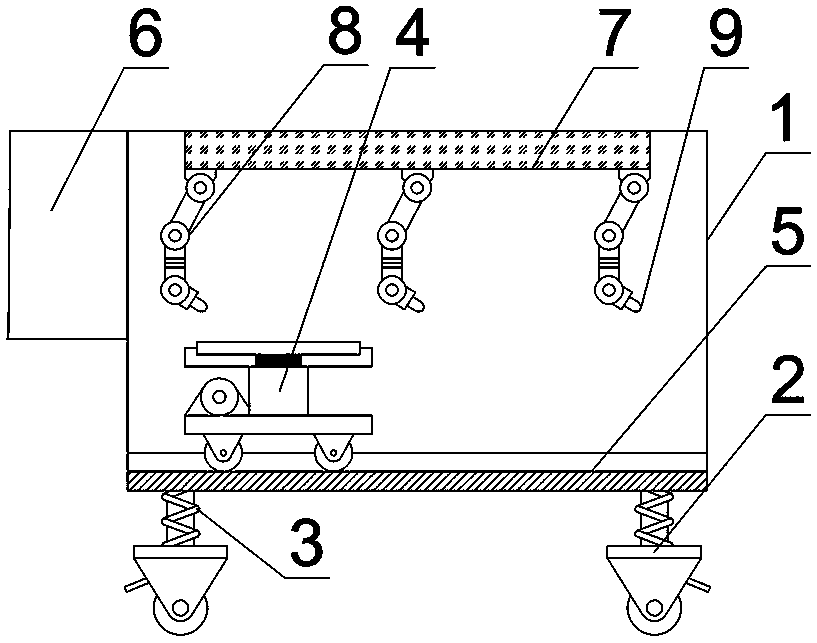

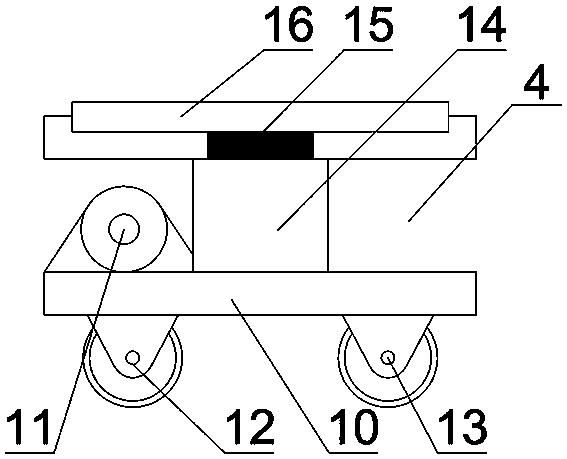

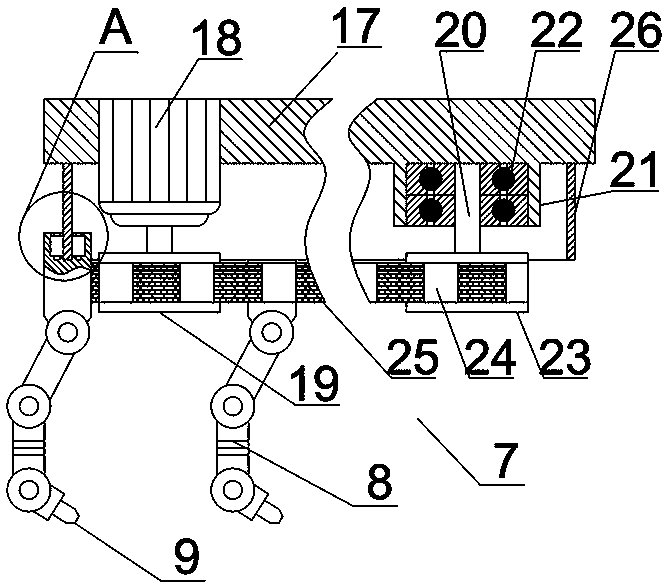

The invention relates to hydroelectric equipment with an anti-blocking function. The hydroelectric equipment comprises a shell, a supporting column, a drying mechanism, two push mechanisms and two limiting mechanisms are arranged in the shell, and each limiting mechanism comprises a telescopic assembly and a limiting assembly. Each telescopic assembly comprises a vertical rod, a driving unit, a telescopic frame, a connecting plate, two cross rods, two sliding blocks and two transmission blocks. Each limiting assembly comprises a cross plate, a rotary shaft, a roller and waterproof cloth. Eachpush mechanism comprises a supporting plate, a water turbine, a rotary disc, a driving rod, a driven rod, a push block and two limiting assemblies. According to the hydroelectric equipment with the anti-blocking function, blocking of the bottom in the shell can be reduced through the limiting mechanisms and the push mechanisms, so that the hydroelectric equipment is higher in practicality; and thebottom in the shell can be dried through the drying mechanism when the hydroelectric equipment is not used, equipment corrosion caused by accumulated water is avoided, and therefore the service lifeof the hydroelectric equipment can be prolonged.

Owner:国家电投集团广西长洲水电开发有限公司

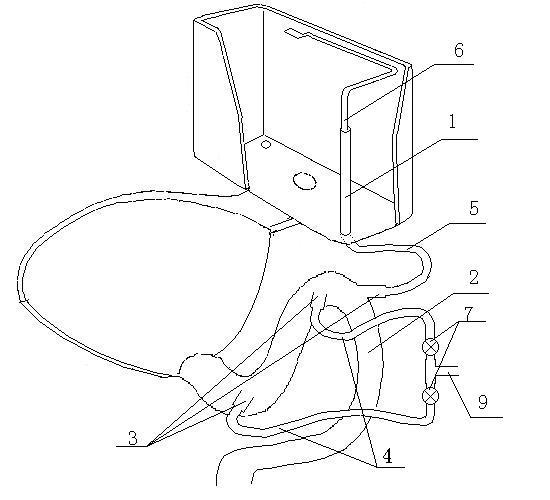

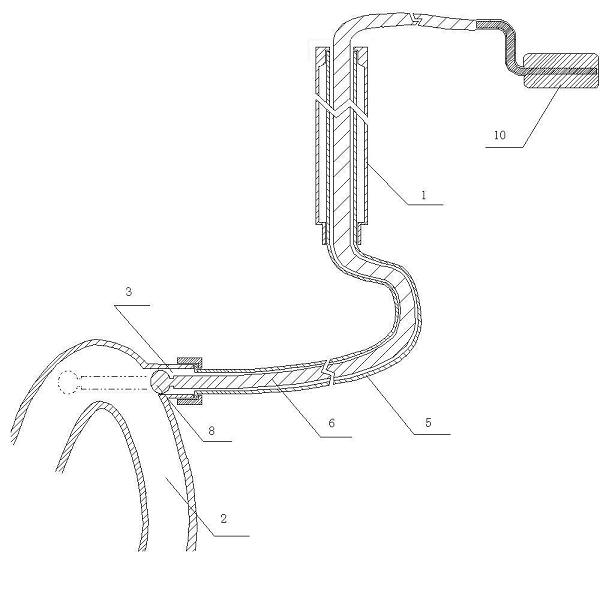

Anti-blocking toilet with dredging device

InactiveCN102619270ADo not change the main structureEasy to acceptWater closetsDomestic plumbingWater flowEngineering

The invention discloses an anti-blocking toilet with a dredging device. In order to solve the blocking problem of toilets simply, efficiently and hygienically, one or more dredging holes (3) are formed in suitable position(s) of a drainage pipe of the toilet, and each dredging hole (3) is connected with each corresponding water pipe (4) or casing pipe (5). The other end of each water pipe (4) is connected with a tap water pipe (9) through a valve (7); when the toilet is blocked, the blocked position is scoured directly by opening the valve (7); the other end of each casing pipe (5) is fixed in a water box body or at other positions of the toilet; a dredging rod (6) made of elastic materials, such as a steel wire spring can penetrate into the dredging hole(s) (3) from the upper port(s) of the casing pipe(s) (5), and then penetrate into the drainage pipe through the dredging holes (3) to dredge the blocked position. The water flow scouring operation can be carried out only by opening and closing the valve (7); and the dredging rod (6) has stronger dredging capability; and the valve (7) and the dredging rod (6) have respective advantages and supplement each other.

Owner:张莉

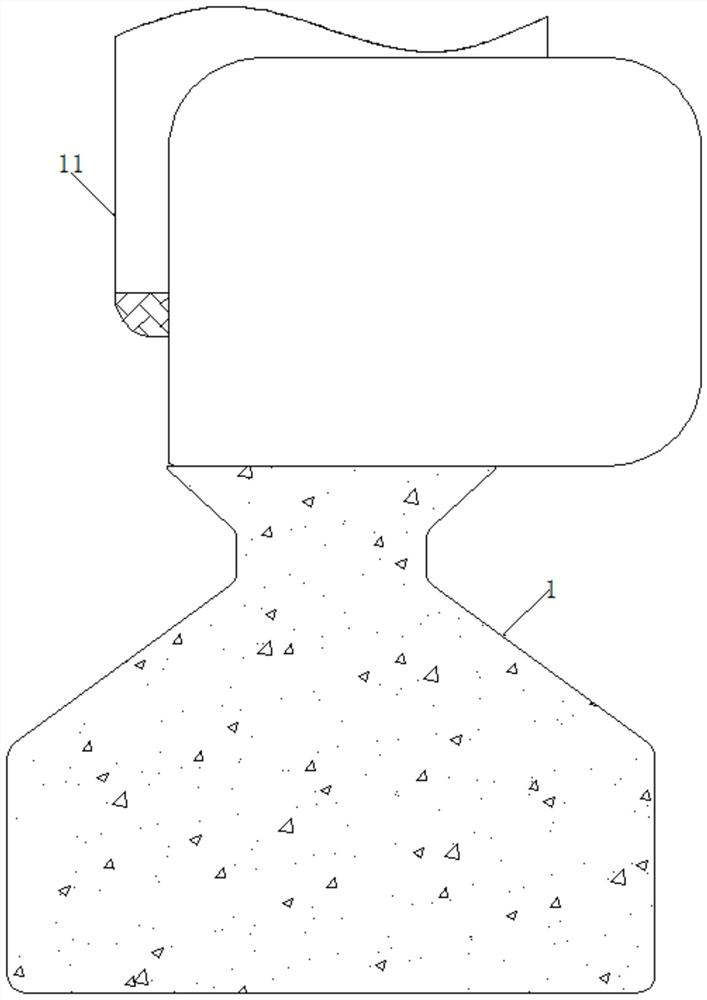

Feeding device with anti-blocking function and used for new material processing

InactiveCN112110063AIncrease linkageHigh degree of automationLarge containersStructural engineeringProcess engineering

The invention relates to the related technical field of new materials, and discloses a feeding device with an anti-blocking function and used for new material processing. The feeding device comprisesa shell, wherein a supporting rod is fixedly connected to the interior of the shell. By the material pressure effect and the magnetic induction line cutting principle, the falling condition of materials is controlled, dredging operation of the materials is triggered, the linkage between structures is improved, and the automation degree is high; flowing of the materials is automatically controlledthrough the combined action of a second rotary disc, a material pipe, a third rotary disc, connecting rods, rotary plates and baffles, and when the material blockage condition occurs, discharging operation is automatically stopped, the extrusion effect of the materials is relieved, and dredging of the materials is promoted; and extruded materials are automatically loosened through the combined action of a stirring block, an inverted U-shaped rod and a first rotary disc, the flowing pressure between material particles in a feeding port is damaged, the blockage problem in the material discharging process is solved, flowing of the material is promoted, and the feeding operation is convenient to carry out.

Owner:吴慧敏

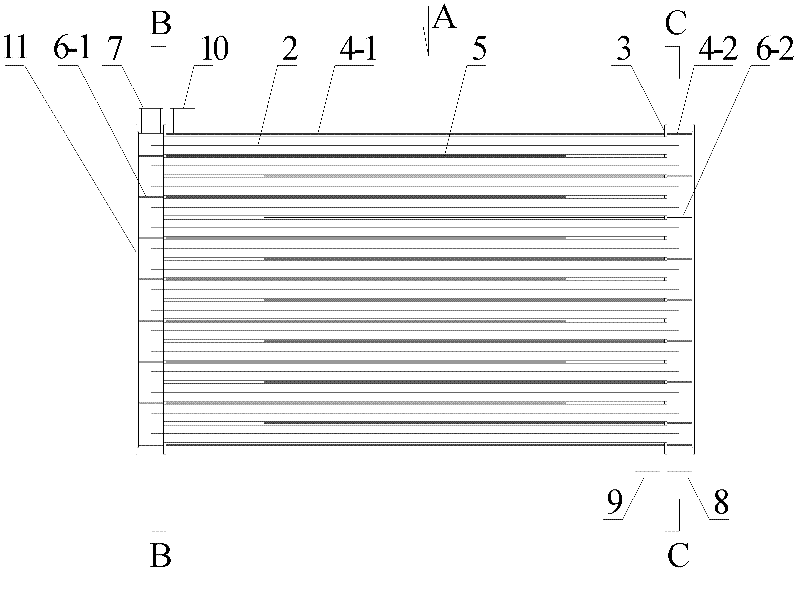

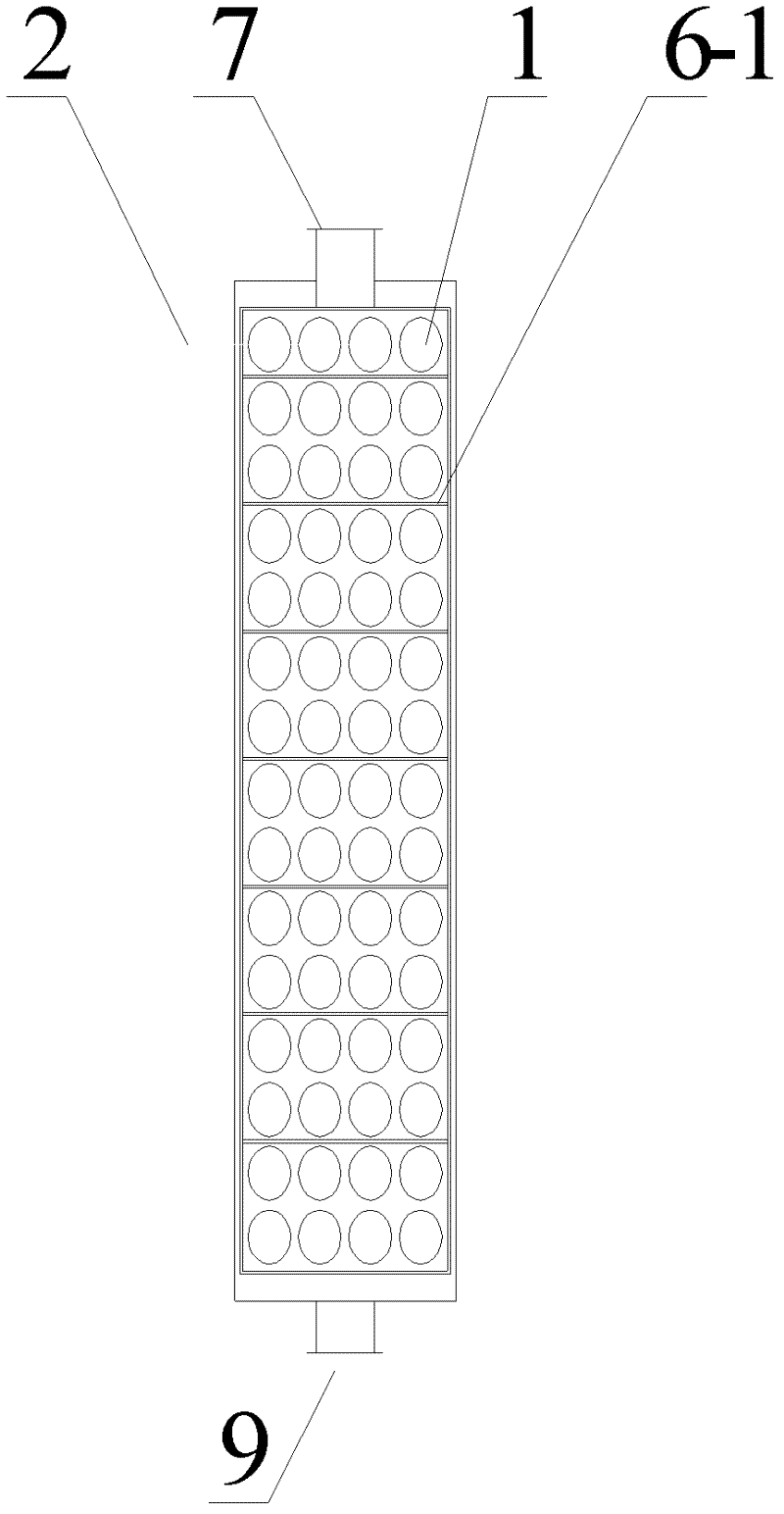

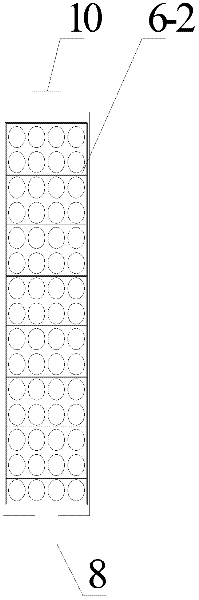

Mine three-proof heat exchanger

InactiveCN101769691AReliable exchangeFully contactedHeat exchanger casingsStationary tubular conduit assembliesSocial benefitsEconomic benefits

The invention discloses a mine three-proof heat exchanger, which comprises a streamline type shell, a heat exchanging bundle positioned in the shell, and a plurality of baffle plates, wherein the plurality of baffle plates are sequentially arranged along the direction of the cross section of the shell; the baffle plates are provided with water flow passageways; the water flow passageways among the baffle plates are kept at a certain inclined angle; the peripheries of the baffle plates are fixed on the inner wall of a shell; and the heat exchanging bundle is axially penetrated through the water flow passageways of the baffle plates along the shell. The water flow passageways on the baffle plates baffle and limit the direction of industrial water, therefore, the mine three-proof heat exchanger reduces the flow speed of the water flow, guarantees the water flow to be adequately and evenly contacted with the outer wall of the heat exchanging bundle, greatly improves the energy exchange, reduces the production cost, improves the economic benefit and the social benefit of enterprises, and is particularly suitable for various mines which contain water inflow with high impurity content, high mineralization and high corrosivity.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

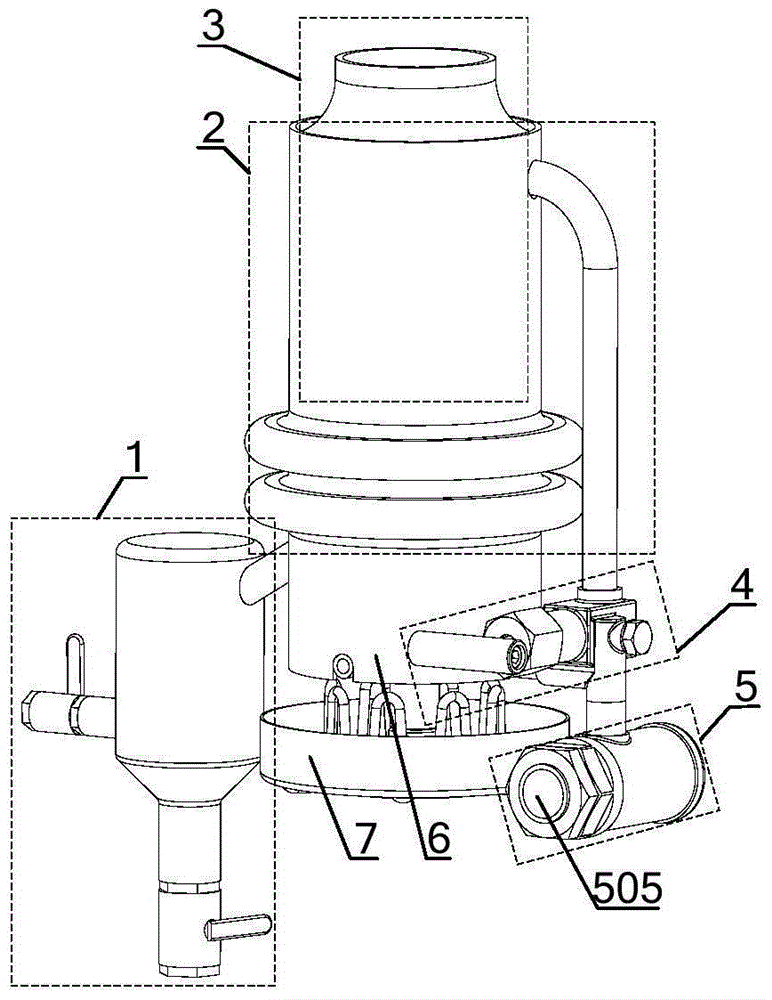

Intelligent sand measurement mobile air lift pump and using method thereof

PendingCN113431785AAdd recoil functionWith anti-blocking functionSpecific fluid pumpsPump componentsThermodynamicsSlag

The invention relates to the field of liquid treatment, in particular to an intelligent sand measurement mobile air lift pump and a using method thereof. The intelligent sand measurement mobile air lift pump comprises a double-hole air lift pump and an air lift pump intelligent device. Firstly, a set of air lift pump with lifting and moving functions is invented; a set of sensors for automatically measuring sand to sense the amount of sand slag dirt in liquid; the other set of air lift pump sensors sense the operation state of the air lift pump and lift the air lift pump; then, the air lift pump can be intelligently started and stopped to discharge the dirt according to the amount of the sand slag dirt under the liquid through the two sets of automatic measuring and lifting devices; when the dirt blockage is sensed, the dirt blocking a main liquid pipe can be cleaned out by lifting the air lift pump and performing backflushing; and the function of intelligently controlling the air lift pump is achieved. The defects that the amount of dirt cannot be perceived under liquid and air lifting cannot be carried out due to the fact that a common air lift pump port is buried by a large amount of sand slag are overcome, and meanwhile the problem that the air lift pump is blocked is well solved. According to the invention, the carbon emission is reduced through an energy-saving and pollution-reducing technology.

Owner:王学千

Sludge clearing equipment with anti-blocking function

InactiveCN112663712AWith anti-blocking functionCleanup impactSoil-shifting machines/dredgersFiltration separationSludgeDrive shaft

The invention relates to sludge clearing equipment with an anti-blocking function. The equipment comprises a collecting box and two floating plates, the collecting box is in a cuboid shape, the two floating plates are fixed to the two sides of the collecting box, an executing mechanism and an auxiliary mechanism are arranged on the collecting box, the executing mechanism comprises a power assembly and two executing assemblies, the power assembly comprises a driving motor, a transmission shaft, a screw rod, a fixed pipe, an auxiliary pipe and a driving bevel gear, each executing assembly comprises a driven bevel gear, a water pipe, a filter screen, a bearing, a rotating shaft, a connecting hole and a drainage hole, and the auxiliary mechanism comprises a sealing block, a moving ring, two transmission assemblies and two auxiliary assemblies. According to the sledge clearing equipment with the anti-blocking function, the sludge clearing function is achieved through the executing mechanism, in addition, the function of cutting off aquatic plants is achieved through the auxiliary mechanism, and the situation that sludge clearing is affected due to the fact that water inlet holes are blocked by the aquatic plants is prevented.

Owner:南京伊都锦环保科技有限公司

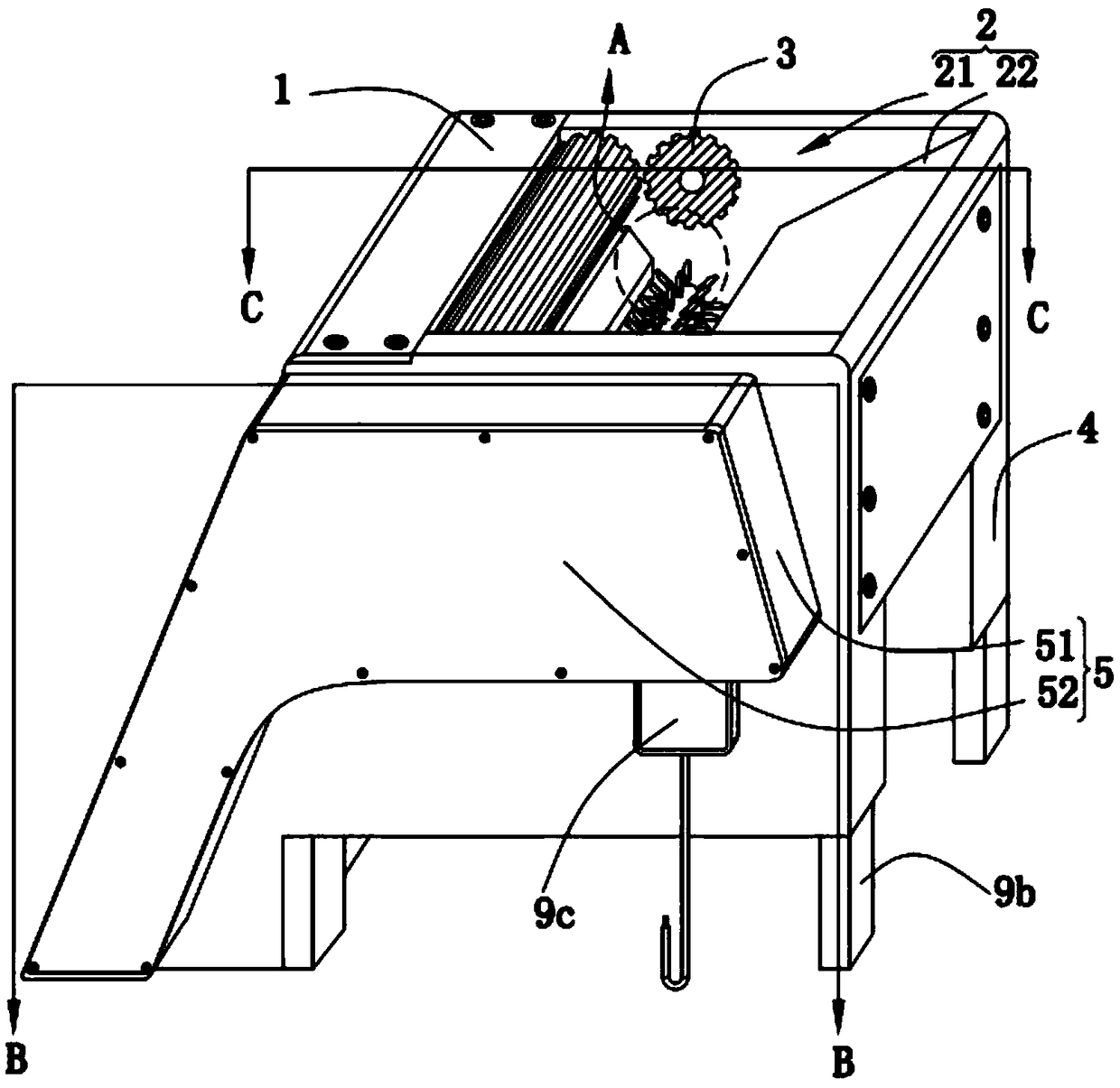

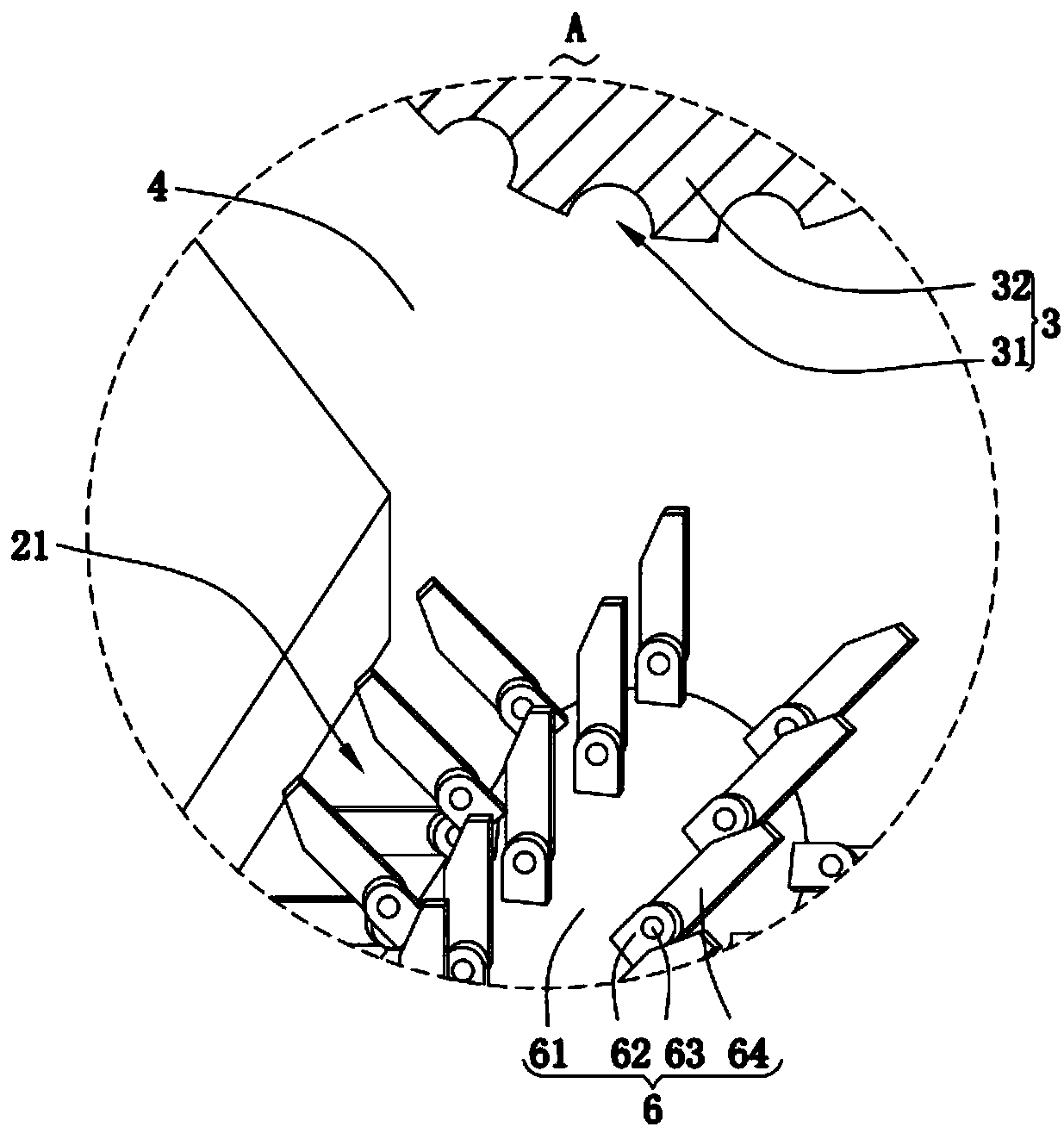

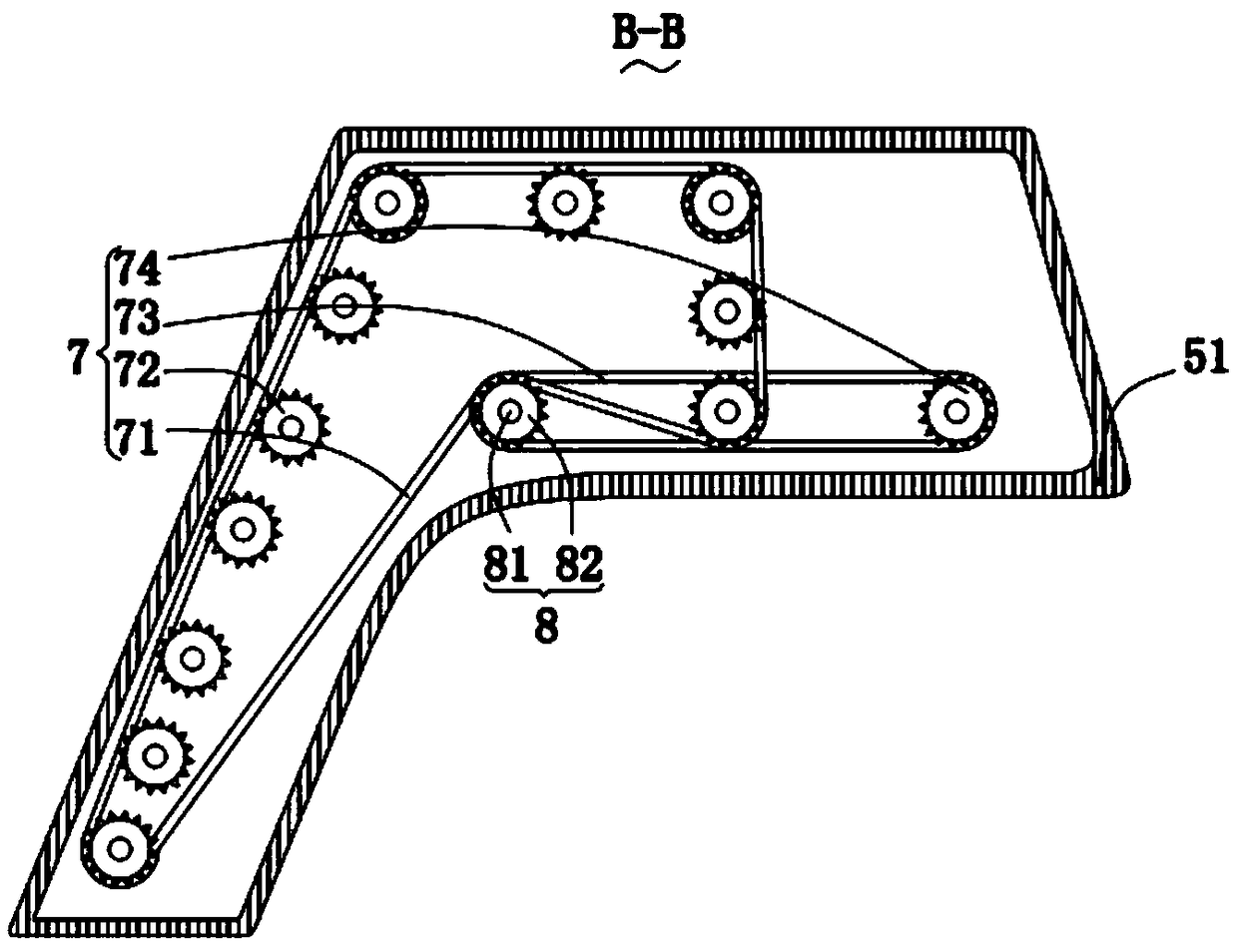

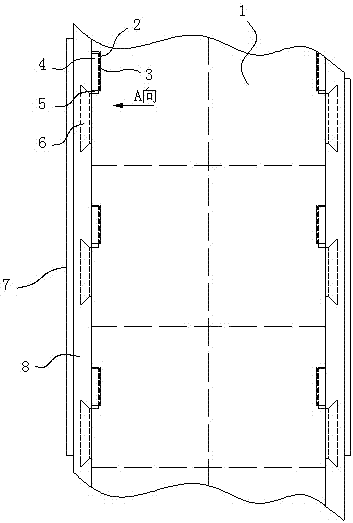

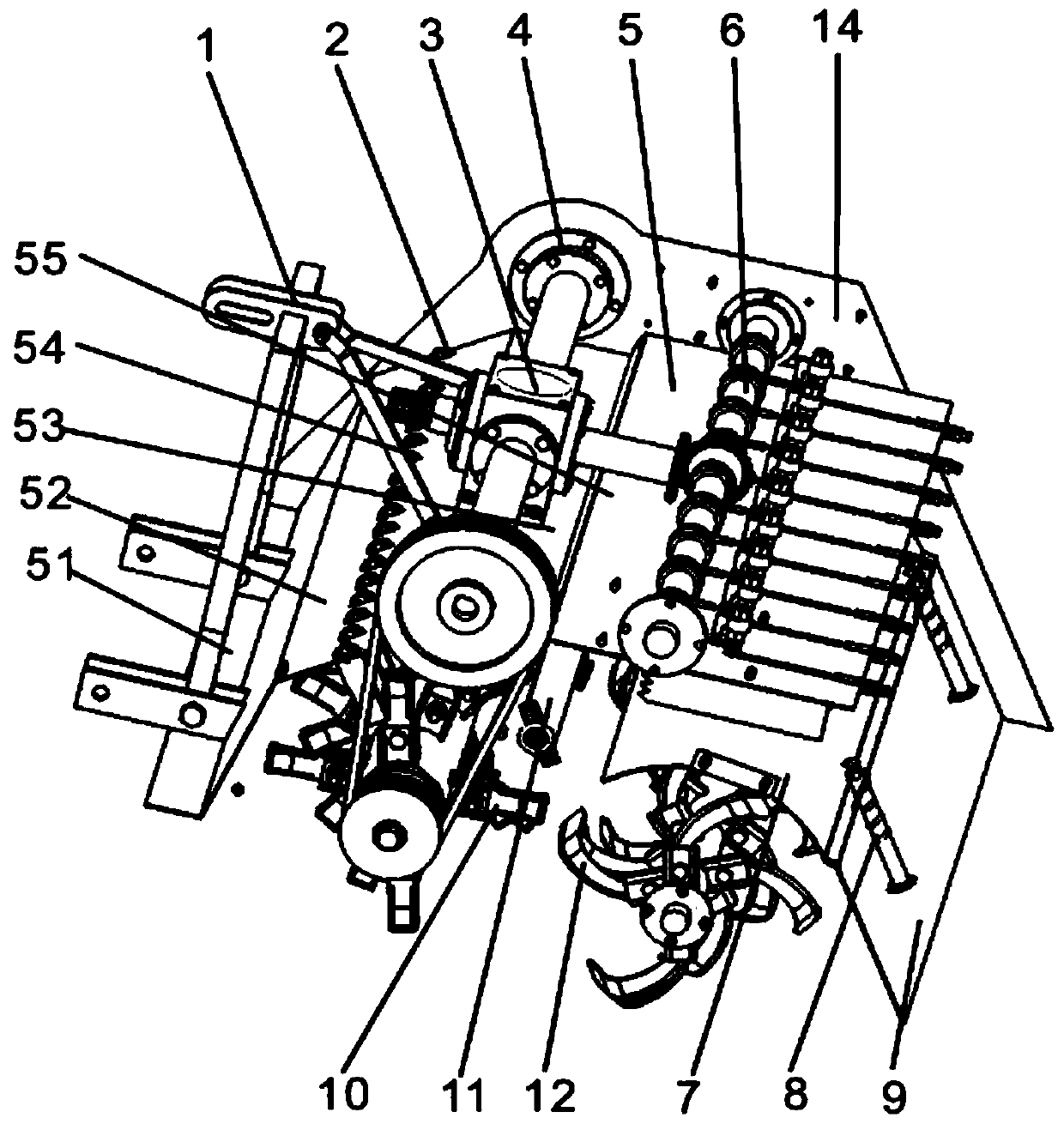

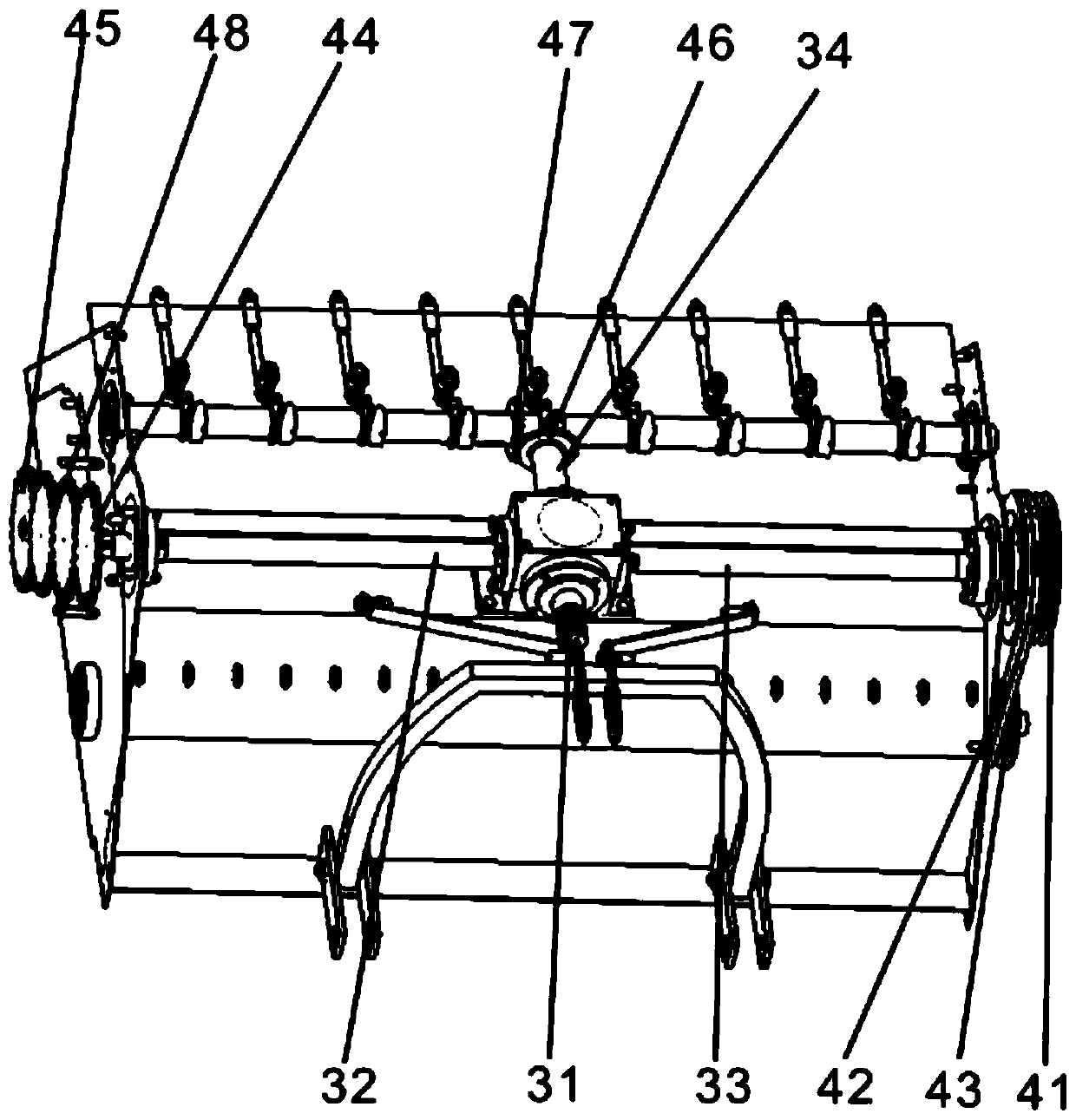

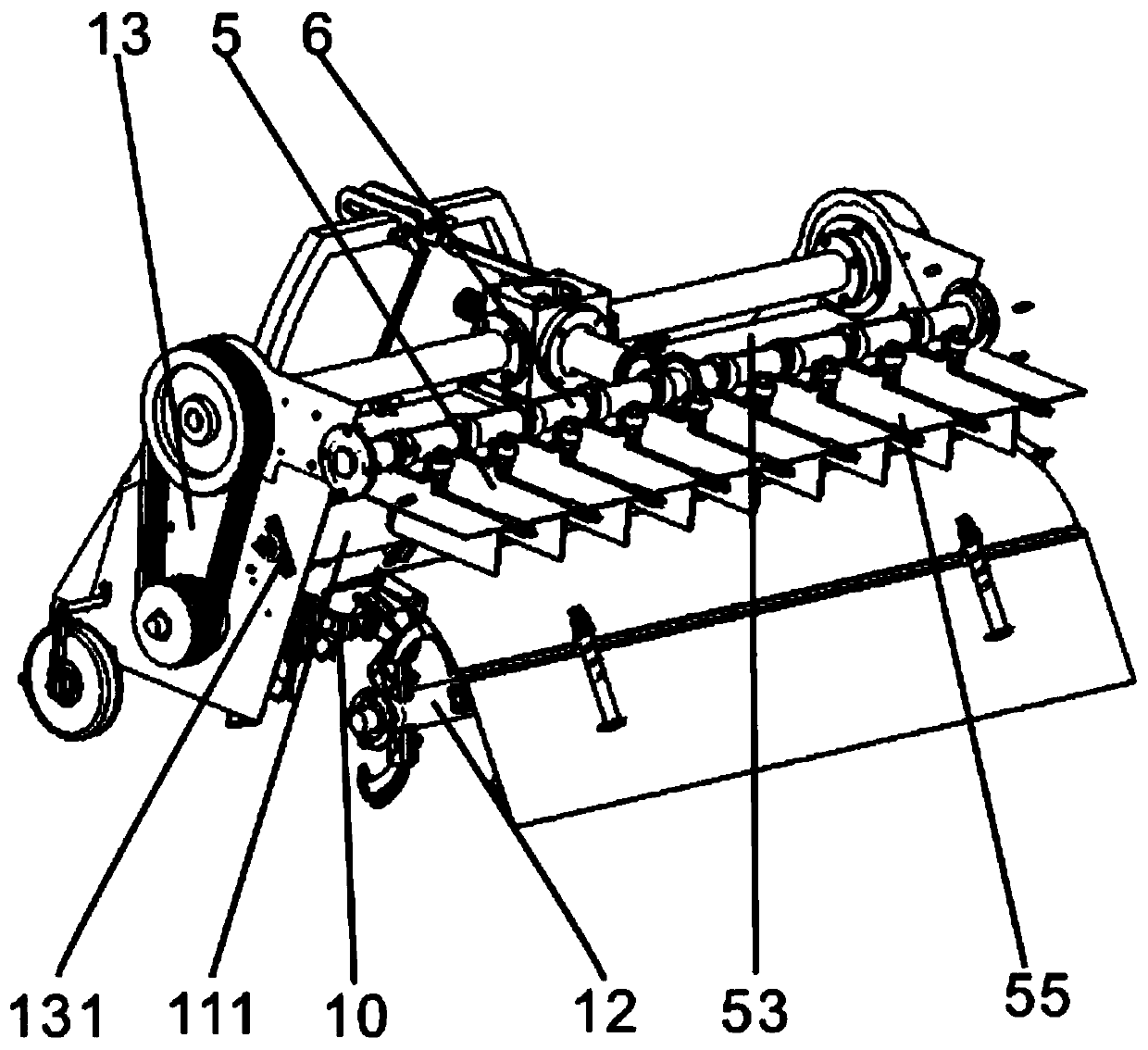

Wheat straw crushing and field returning device

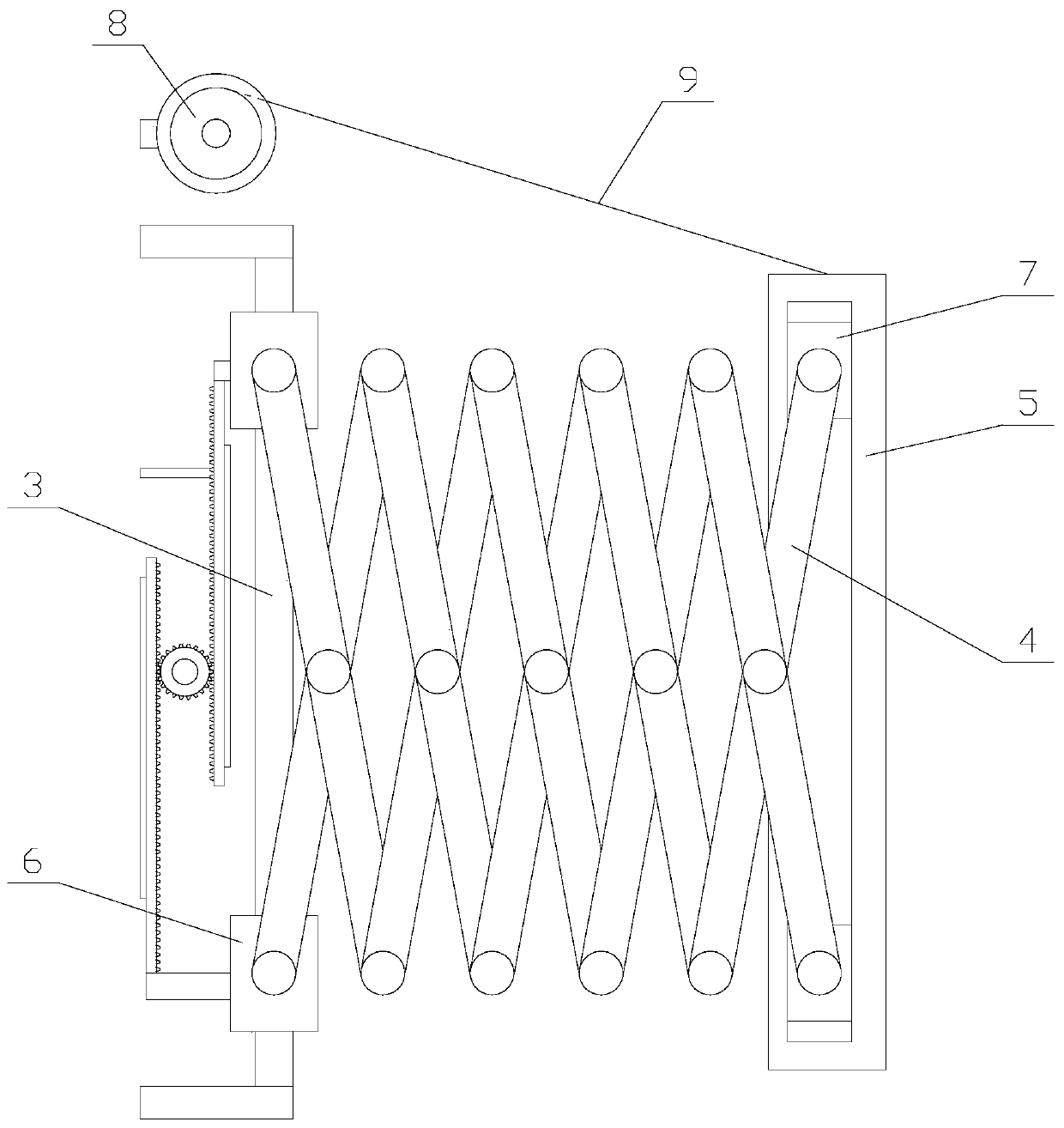

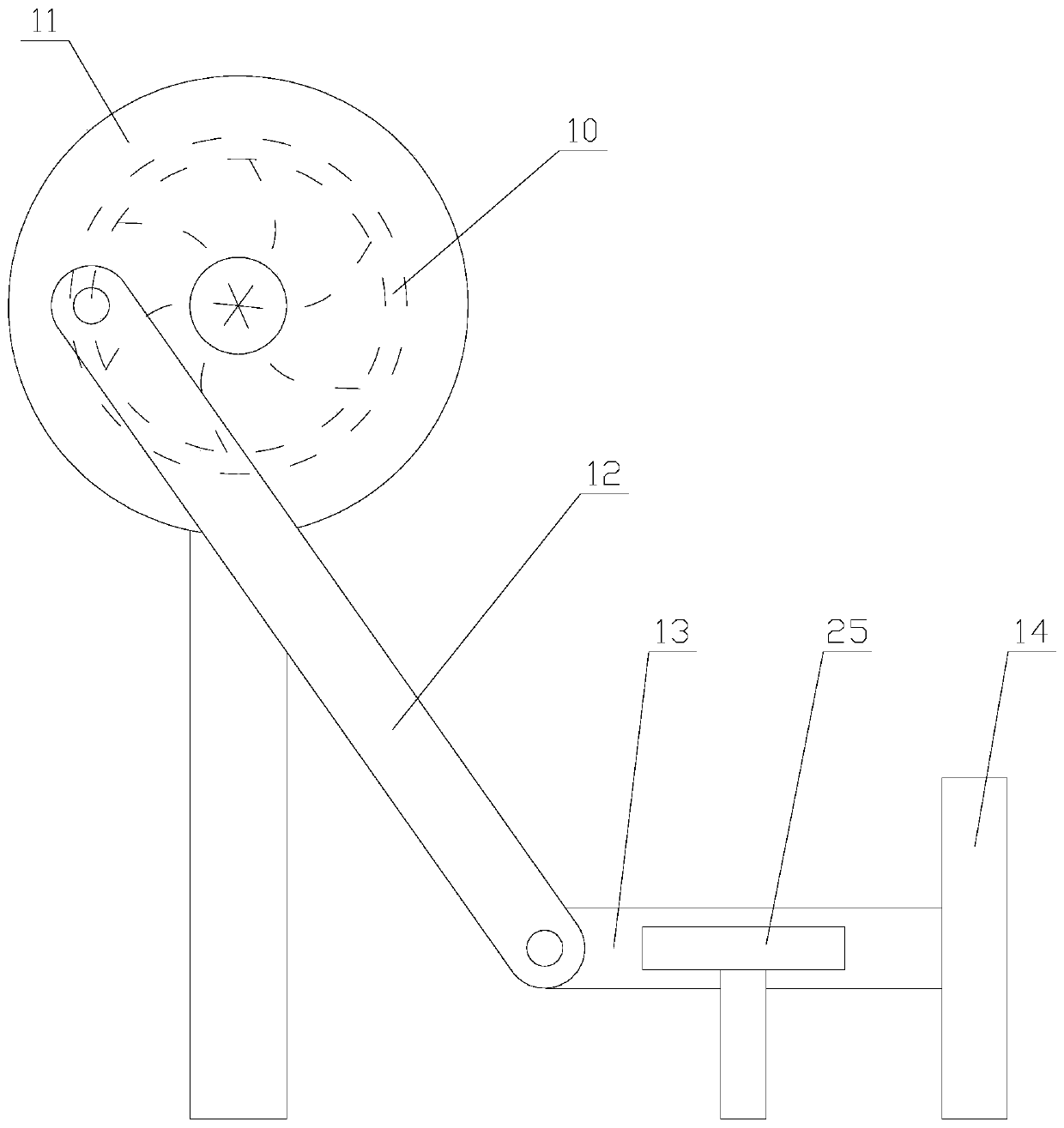

The invention relates to the field of agriculture, in particular to a wheat straw crushing and field returning device. The wheat straw crushing and field returning device comprises a maintenance plate, a discharging structure, a feeding structure, a shell, a protective structure, a crushing structure, a transmission structure, a driving structure, an anti-plugging structure, a discharging channel,supporting legs and a junction box; the driving structure for driving and the transmission structure for transmission are arranged in protective structure of the side wall of the shell, the transmission structure is connected to the feeding structure for transporting the material, the crushing structure for crushing and the anti-plugging structure for preventing plugging, wherein the feeding structure, the crushing structure and the anti-plugging structure are located in the shell, and the feeding communicates with the discharging structure used for adding the material and located in the shell; and the anti-plugging structure is arranged in the discharging channel used for discharging the wheat straw. According to the wheat straw crushing and field returning device, the discharging structure is combined with the feeding structure to be used, the wheat straw can be conveniently added into the device, the feeding is more convenient and fast, the feeding labor amount is reduced, the crushing is more through the combination of the anti-plugging structure with the crushing structure, and the crushing quality is improved.

Owner:许美凤

Bridge with anti-blocking function

ActiveCN106884381AGuaranteed unobstructedEnsure traffic safetyBridge structural detailsForeign matterStructural engineering

The invention relates to the technical field of bridges, and particularly relates to a bridge with an anti-blocking function. The bridge comprises a bridge body, the bridge body comprises a bridge surface, bridge side girders are correspondingly arranged on the two sides of the bridge surface, a plurality of drainage holes are arranged on the bridge side girder, a solar panel is arranged on the outer side surface of the bridge side girder, a telescopic cylinder is arranged on one side of the upper part of the drainage hole on the inner side surface of the bridge side girder, a waterproof sealing box is installed on the telescopic cylinder, a cylinder shaft hole is arranged on the left side surface of the waterproof sealing box, a seal ring is embedded in the cylinder shaft hole, a pushing plate is arranged at the end tip of a cylinder shaft, extending outside the cylinder shaft hole, of the telescopic cylinder, a grid mesh is arranged on the drainage hole to form first-level blocking prevention, the cylinder shaft on the cylinder cleans foreign matters on the drainage hole to form second-level blocking prevention; the bridge has the multiple anti-blocking function, the smoothness of the drainage hole is guaranteed, water is guaranteed not to be accumulated on the bridge surface, the safe passing of a vehicle is finally guaranteed, and the occurrence of potential safety hazards is completely eradicated.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

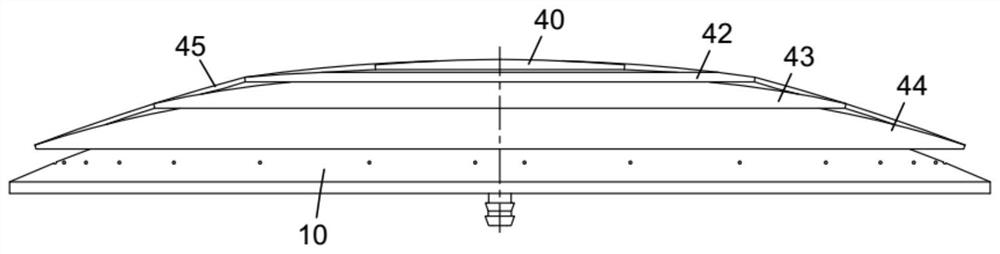

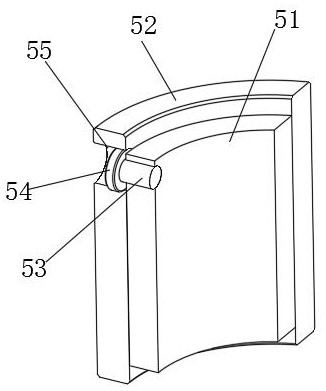

Anti-blocking aeration nozzle

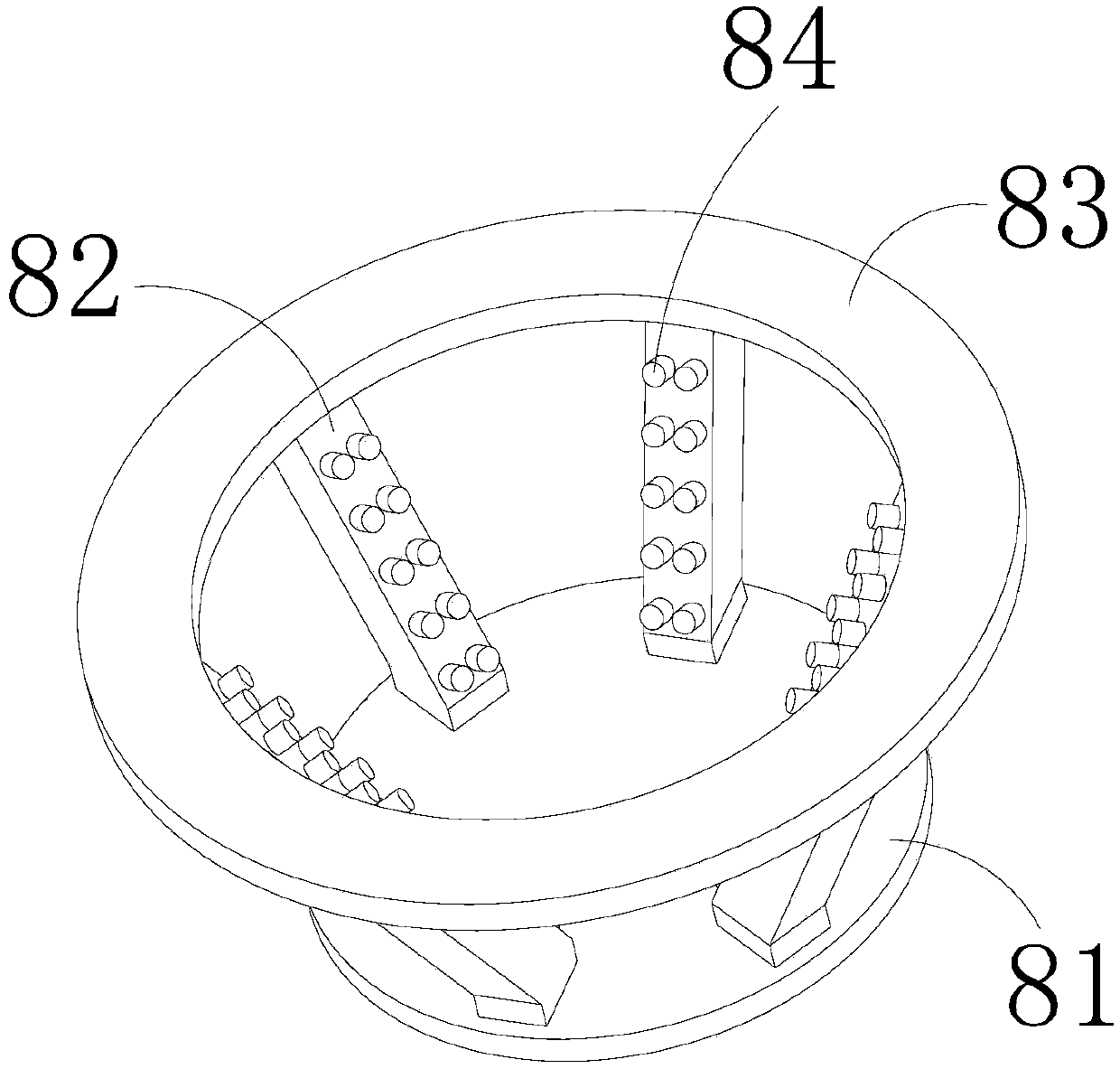

PendingCN113135615AWith anti-blocking functionWater treatment parameter controlTreatment using aerobic processesGas supplyMechanics

A disclosed anti-blocking aeration nozzle comprises a nozzle body provided with a plurality of aeration holes, a valve element is arranged in each aeration hole in a matched mode, all the valve elements are located on an elastic piece, the elastic piece is connected with the nozzle body in a sealed mode to form an air chamber, and the air chamber is connected with an air supply pipeline. Initially, water pressure acts on the elastic piece, and the valve elements block the aeration hole; and when aeration is needed, an aerator supplies air into the air chamber through the air supply pipeline, the pressure in the air chamber is increased, external water pressure is overcome, the air chamber expands, and the elastic piece drives the valve elements to open the aeration hole. According to the aeration nozzle disclosed by the invention, during aeration, gas in the gas chamber is aerated outwards, and dirt in a water body cannot enter the aeration holes or the gas chamber; and when aeration is stopped, under the action of water pressure, the aeration hole is blocked by the valve element, the air chamber is sealed, and dirt in water cannot enter the aeration hole or the air chamber. Therefore, the aeration nozzle disclosed by the invention has an anti-blocking function.

Owner:PULIZI ENVIRONMENT TECH SUZHOU CO LTD

Cement homogenizing equipment with pre-crushing function

InactiveCN109225014AReduce consumptionImprove energy savingTransportation and packagingRotary stirring mixersWater turbineSpiral blade

The invention provides cement homogenizing equipment with a pre-crushing function. The cement homogenizing equipment comprises an equipment tank body, a driving mechanism, a dispersing bin, a sievingbin, a mixing and discharging bin, an auxiliary mechanism and a pre-crushing mechanism, wherein the driving mechanism is arranged at the top part of the equipment tank body, and is driven by a water turbine; the driving mechanism is in output connection to a main shaft; the main shaft is fixed at the middle position of the equipment tank body, the upper part of the main shaft penetrates through atransmission box, and the lower part of the main shaft penetrates through the dispersing bin, the sieving bin and the mixing and discharging bin; the dispersing bin is internally provided with a dispersing knife disc, a back impacting plate and horizontal and vertical spiral conveyors; spiral blades of the spiral conveyors are respectively provided with sieving holes; sieving holes are formed on the back impact plate; the sieving bin is provided with an air sieving machine and a vibratory sieving net; the mixing and discharging bin is provided with mechanical stirring blades, a pneumatic stirring pipe and a circular stirring pipe; the auxiliary mechanism comprises a dust suctioning machine and a settling tank. According to the cement homogenizing equipment provided by the invention, the design is simple and practical, the homogenizing and mixing effects are enhanced, so that the cement homogenizing equipment is very suitable for being applied on the cement production process.

Owner:罗永山

Cement homogenizing equipment with automatic charging function

InactiveCN109227943AAvoid build-up cloggingGood energy saving effectDischarging apparatusCement mixing apparatusAutomatic controlScrew conveyor

The invention provides cement homogenizing equipment with an automatic charging function. The cement homogenizing equipment comprises an equipment tank body, a driving mechanism, a dispersing bin, a sieving bin, a mixing and discharging bin, an auxiliary mechanism and a charging mechanism, wherein the driving mechanism is arranged at the top part of the equipment tank body, and is driven by a water turbine; the driving mechanism is in output connection to a main shaft; the main shaft is fixed at the middle position of the equipment tank body, and the lower part of the main shaft penetrates through the dispersing bin, the sieving bin and the mixing and discharging bin; the dispersing bin is internally provided with a dispersing knife disc, a back impacting plate and spiral conveyors; spiralblades of the spiral conveyors are respectively provided with sieving holes; sieving holes are formed on the back impact plate; the sieving bin is provided with an air sieving machine and a vibratorysieving net; the mixing and discharging bin is provided with mechanical stirring blades, a pneumatic stirring pipe and a circular stirring pipe; the auxiliary mechanism comprises a dust suctioning machine and a settling tank; the charging mechanism is arranged above a feeding port. According to the cement homogenizing equipment provided by the invention, the charging speed can be automatically controlled according to the production progress, the homogenizing and mixing effects are good and the occupied space is small.

Owner:罗永山

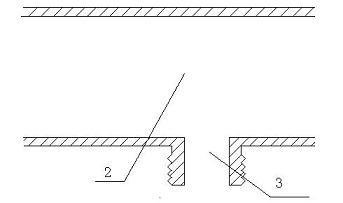

A method of making an anti-blocking rainwater grate

ActiveCN104831808BReduce accumulationWith anti-blocking functionSewerage structuresFoundry mouldsEngineeringTweezers

Owner:BCEG INT

Organic fertilizer production process

PendingCN108516885AFast deliveryIncrease the feeding speedBio-organic fraction processingExcrement fertilisersBiochemical engineeringOrganic fertilizer

The invention relates to the field of organic fertilizer production, in particular to an organic fertilizer production process. The process adopts a smashing machine which comprises a maintenance board, a discharging structure, a feeding structure, a housing, a protecting structure, a smashing structure, a transmission structure, a driving structure, an anti-blocking structure, a discharging channel, supporting legs and a wiring box; the driving structure for driving and the transmission structure for transmission are arranged in the protecting structure on the side wall of the housing; the transmission structure is connected to the feeding structure for conveying material cooperatively, the smashing structure for smashing and the anti-blocking structure for preventing blocking, wherein the feeding structure, the smashing structure and the anti-blocking structure are located in the housing; the anti-blocking structure is arranged in the discharging channel for discharging wheat straw.By the cooperative use of the discharging structure and the feeding structure, wheat straw can be conveniently added into the device, feeding is more convenient and faster, and the workload of feedingis reduced; by the cooperative use of the anti-blocking structure and the smashing structure, smashing is more complete, and the smashing quality is improved.

Owner:许美凤

Fertilizer applying device for yellow peach planting

InactiveCN110679264ASpray evenlyQuick changePressurised distribution of liquid fertiliserSprayerAgricultural engineering

The invention discloses a fertilizer applying device for yellow peach planting. The device comprises a mixing tank, a rotating shaft is mounted in the mixing tank, a plurality of horizontal stirring blades are mounted on the rotating shaft, the rotating shaft is connected with a rotating device, a water inlet and a feeding port are formed in the mixing tank, a water pipe is communicated with the bottom of the mixing tank and communicated with a plurality of vertical pipes, the vertical pipes are coupled with sprayer seats, the sprayer seats comprise longitudinal pipes, the longitudinal pipes are communicated with a plurality of horizontal L pipes, socket pipes are communicated with the outer ends of the L pipes, two opposite L plates are arranged on each socket pipe, an inserting gap is formed between the L plates, sprayers are connected on the socket pipes in an inserted manner, L-shaped clamping blocks are fixed onto two sides of each sprayer, a first elastic part is fixed at the bottom of each L-shaped clamping block, and a high-voltage pump is mounted on the water pipe. The fertilizer applying device is simple in structure and convenient to assemble, leaf fertilizers can be rapidly and uniformly sprayed onto yellow peaches, and the sprayers are rapidly replaced and have a blocking prevention function.

Owner:石门县丰乐果蔬专业合作社

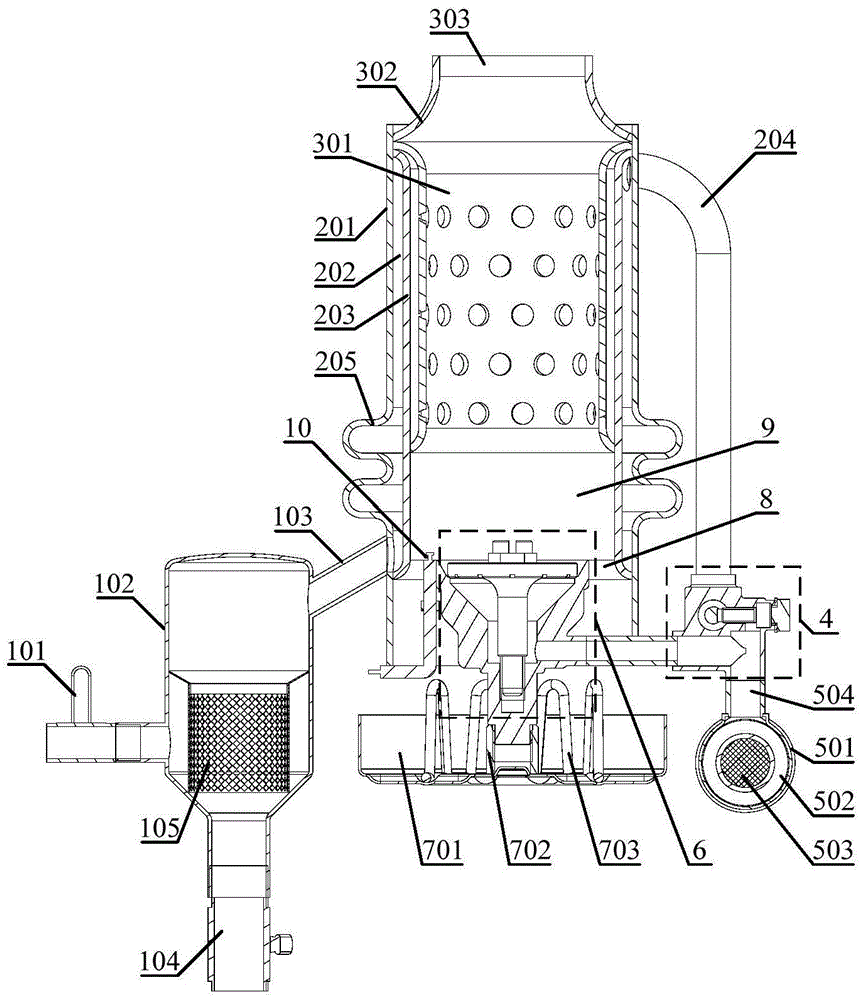

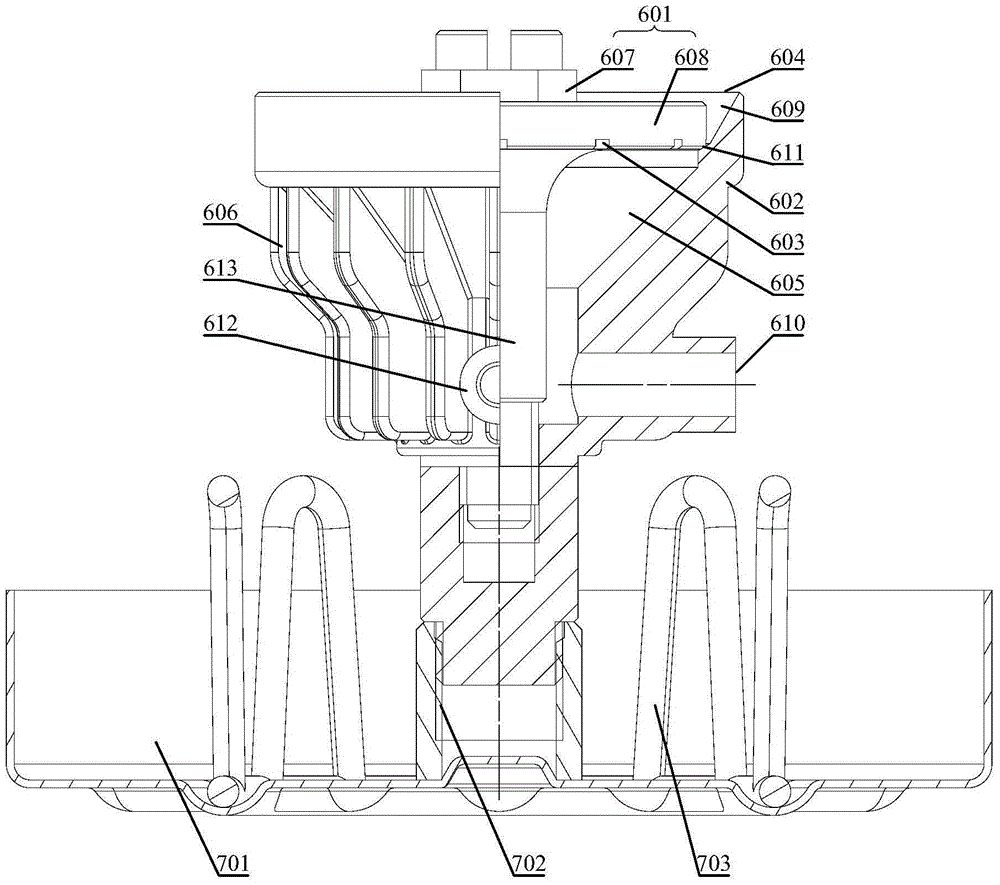

A kind of hydroelectric power generation equipment with anti-blocking function

ActiveCN109026501BWith anti-blocking functionPracticalDrying gas arrangementsHydro energy generationWater turbineStructural engineering

The invention relates to hydroelectric equipment with an anti-blocking function. The hydroelectric equipment comprises a shell, a supporting column, a drying mechanism, two push mechanisms and two limiting mechanisms are arranged in the shell, and each limiting mechanism comprises a telescopic assembly and a limiting assembly. Each telescopic assembly comprises a vertical rod, a driving unit, a telescopic frame, a connecting plate, two cross rods, two sliding blocks and two transmission blocks. Each limiting assembly comprises a cross plate, a rotary shaft, a roller and waterproof cloth. Eachpush mechanism comprises a supporting plate, a water turbine, a rotary disc, a driving rod, a driven rod, a push block and two limiting assemblies. According to the hydroelectric equipment with the anti-blocking function, blocking of the bottom in the shell can be reduced through the limiting mechanisms and the push mechanisms, so that the hydroelectric equipment is higher in practicality; and thebottom in the shell can be dried through the drying mechanism when the hydroelectric equipment is not used, equipment corrosion caused by accumulated water is avoided, and therefore the service lifeof the hydroelectric equipment can be prolonged.

Owner:国家电投集团广西长洲水电开发有限公司

Floor drain for washing machine with anti-blocking function

PendingCN109667332AWith anti-blocking functionImprove interception effectSewerage structuresClimate change adaptationWastewaterPulp and paper industry

The invention discloses a floor drain for a washing machine with an anti-blocking function and relates to the technical field of hardware. The floor drain for the washing machine with the anti-blocking function comprises a floor drain disc, a pipe, a cylinder, a water guiding slot, a collecting mechanism, an annular slot and a water conveying mechanism; the middle part of the floor drain disc is connected with an adaptive connector of a water draining pipe of the washing machine; the top of the pipe is in threaded connection with the middle part of the bottom of the floor drain disc; left andright sides of the cylinder are fixedly arranged on the middle parts on left and right sides of an inner wall of the pipe through connectors; the water guiding slot is longitudinally formed on the middle part of the top of the cylinder and downward stretches; the bottom of the collecting mechanism is fixedly arranged on the top of the cylinder. After wastewater from the washing machine enters intothe pipe of the floor drain for the washing machine with the anti-blocking function, pure cotton threads and hair can be intercepted by an inclined rod and a winding ring in the collecting mechanismand can be further intertwined into a ball by a cylindrical bulge, so that normal use of the water draining system can be guaranteed.

Owner:杭州卓维机械有限公司

Suction type dust concentration sensor with anti-blocking function

PendingCN113484206AWith anti-blocking functionTo achieve anti-blocking effectParticle suspension analysisLaser transmitterThreaded pipe

The invention discloses a suction type dust concentration sensor with an anti-blocking function. The suction type dust concentration sensor comprises a supporting table, a threaded pipe control unit and a dust removal unit; a detection channel is formed in the upper portion of the supporting table, a round hole is formed in the upper end of the supporting table, a laser transmitter is installed in the round hole, a supporting block is fixedly connected to the right portion of the front side of the supporting table, a movable frame is rotationally connected to the front end of the supporting block, and a round plate is fixedly connected to the upper side of the right end of the movable frame; and a sliding hole is formed in the middle of the circular plate, and a threaded pipe is rotationally connected to the middle of the right side face of the circular plate. The threaded pipe control unit is mounted on the right side of the movable frame; the dust removal unit is mounted on the circular plate; and the sensor further comprises a single-chip microcomputer, and the single-chip microcomputer is arranged on the left portion of the front side of the supporting table. When the suction type dust concentration sensor with the anti-blocking function is used, dust accumulated in the suction type dust concentration sensor can be cleaned, blocking is prevented, and therefore the detection result is more accurate.

Owner:常熟市顺欣仪器仪表有限公司

A 3D printer for food processing

The invention discloses a 3D printer for food, which mainly includes a sealed box body, a transmission platform, a raw material box, a mechanical arm and a printing nozzle. The front and rear sides of the bottom of the sealed box body are provided with transmission tracks, and the transmission platform It is connected to the transmission track by transmission; the left side of the sealed box is fixedly connected with a raw material box, and the upper side of the sealed box is provided with a transmission frame, and a printing nozzle is fixedly connected to the top of the mechanical arm; the invention can be processed according to the type of food material Requirements, set up 1‑6 robotic arms to install the print nozzles, the separate area of the raw material box is used to hold different raw materials, which can effectively avoid the phenomenon of odor, the print nozzles can be placed on the printing materials such as dietary fiber to block the nozzles, and can realize a variety of Raw materials can be printed quickly in a short period of time. At the same time, each 3D printing nozzle has a corresponding torque sensor, pressure sensor and heating resistance wire, which is convenient for mediating the corresponding pressure value, temperature and other data of the device, and expanding the types of 3D printing raw materials. Improve printing efficiency and enhance the use value of equipment.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

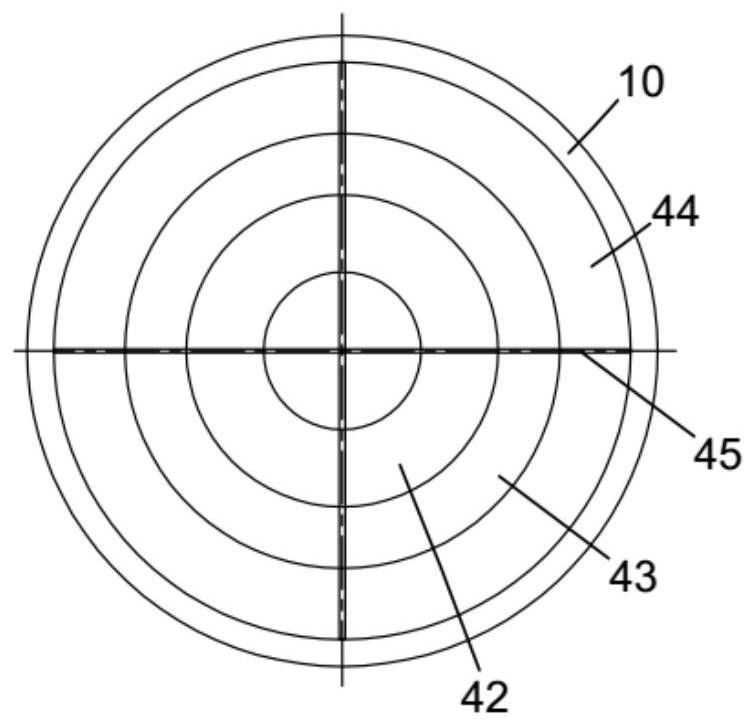

A continuously adjustable integrated anti-clogging screen device

ActiveCN113599885BImprove survivabilityImproved confining compressive strengthStationary filtering element filtersStructural engineeringScreens (device)

The invention discloses a continuously adjustable integrated anti-clogging screen device, which comprises a screen frame and upper screen joints and lower screen joints arranged at both ends of the screen frame; the screen frame includes a plurality of axial frame lines, oblique Axial skeleton lines and adjustable skeleton lines; the axial skeleton lines are connected between the upper screen joint and the lower screen joint and are parallel to the axes of the two, and a plurality of axial skeleton lines are evenly distributed along the circumference to surround the upper screen. The mesh joint and the lower screen joint are coaxial cylindrical skeletons; the oblique skeleton lines are obliquely fixed on the cylindrical skeleton and a plurality of oblique skeleton lines are evenly distributed along the circumference, and there are sets between adjacent two oblique skeleton lines An adjustable skeleton wire running in the same direction as the oblique skeleton wire; the adjustable skeleton wire can move radially to change the gap between the adjustable skeleton wire and the oblique skeleton wires on both sides so as to adjust the porosity of the screen mesh skeleton. The sieve porosity of the present invention can be adjusted in real time according to the change of working conditions, and has anti-clogging function at the same time, which greatly improves the efficiency of repair work.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

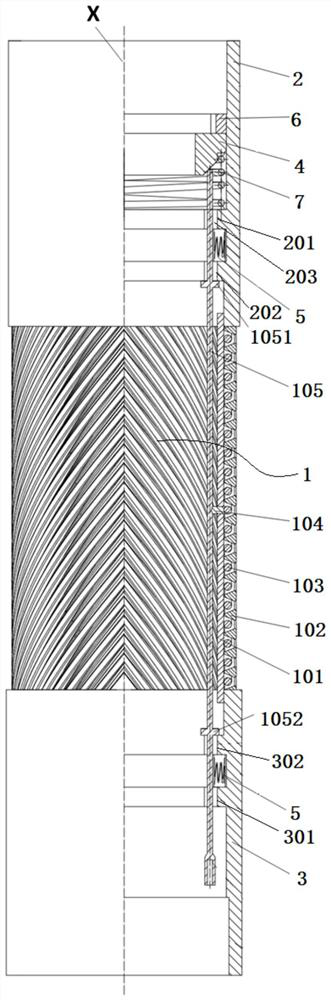

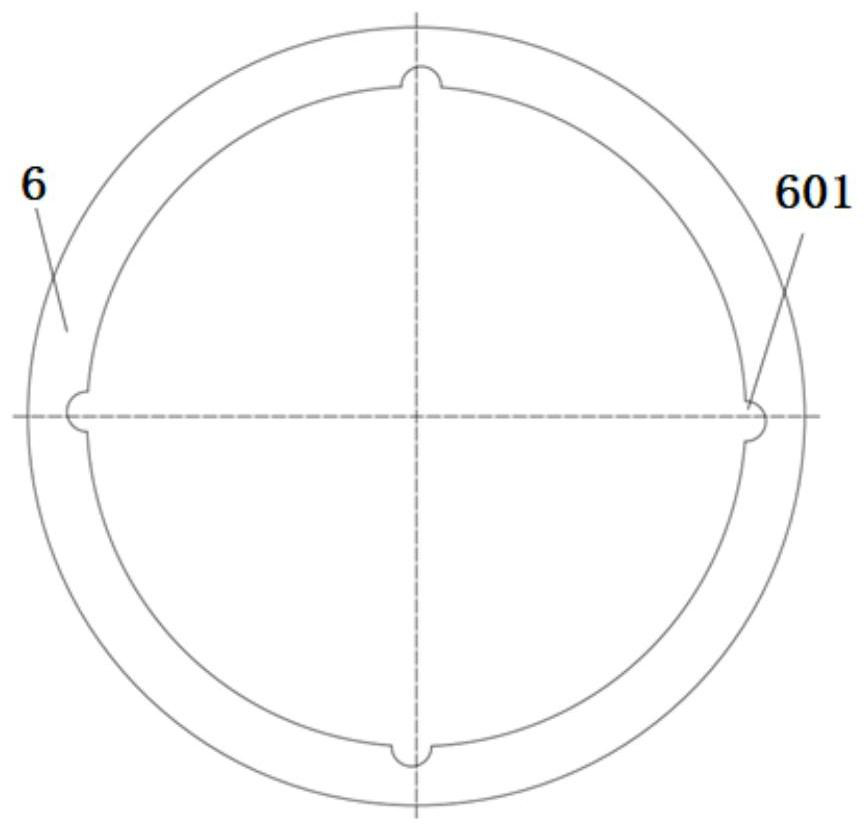

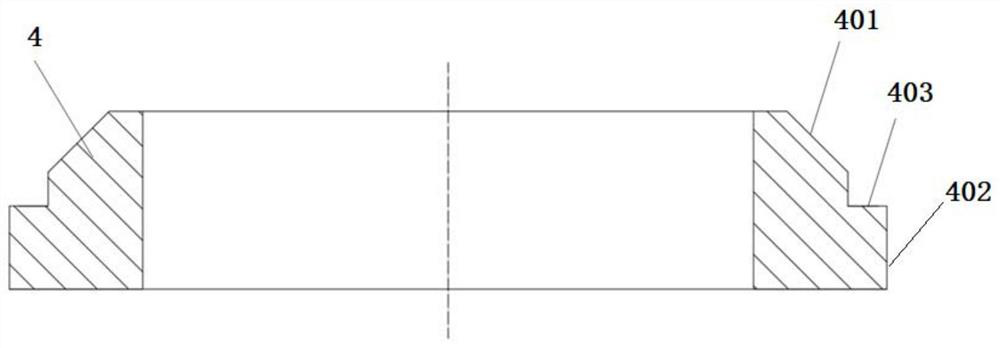

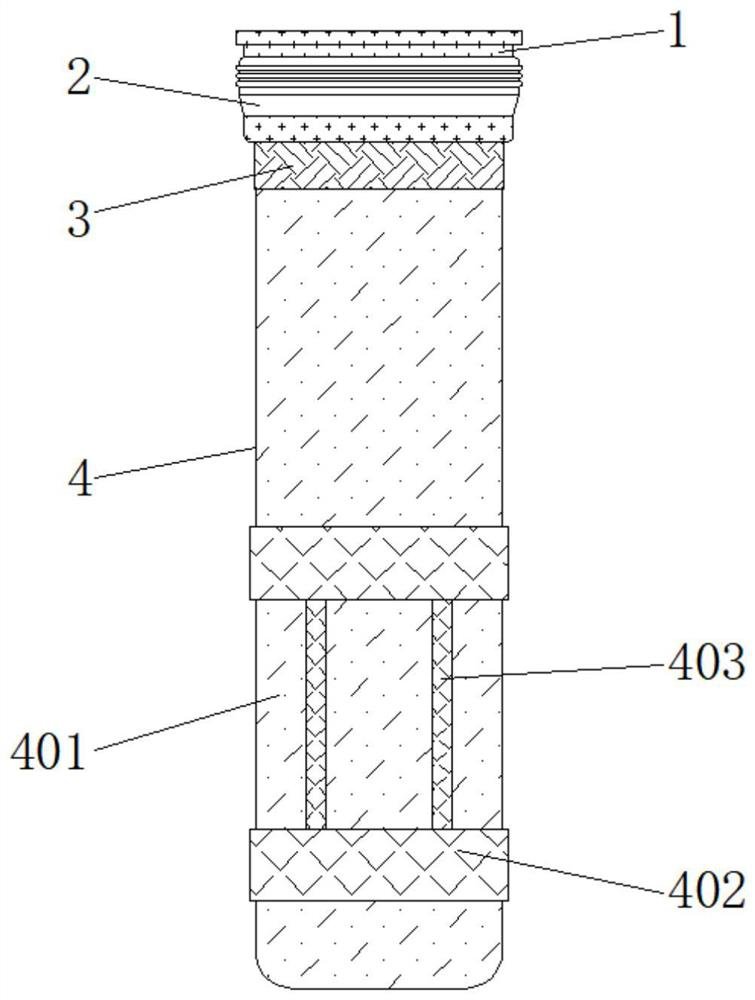

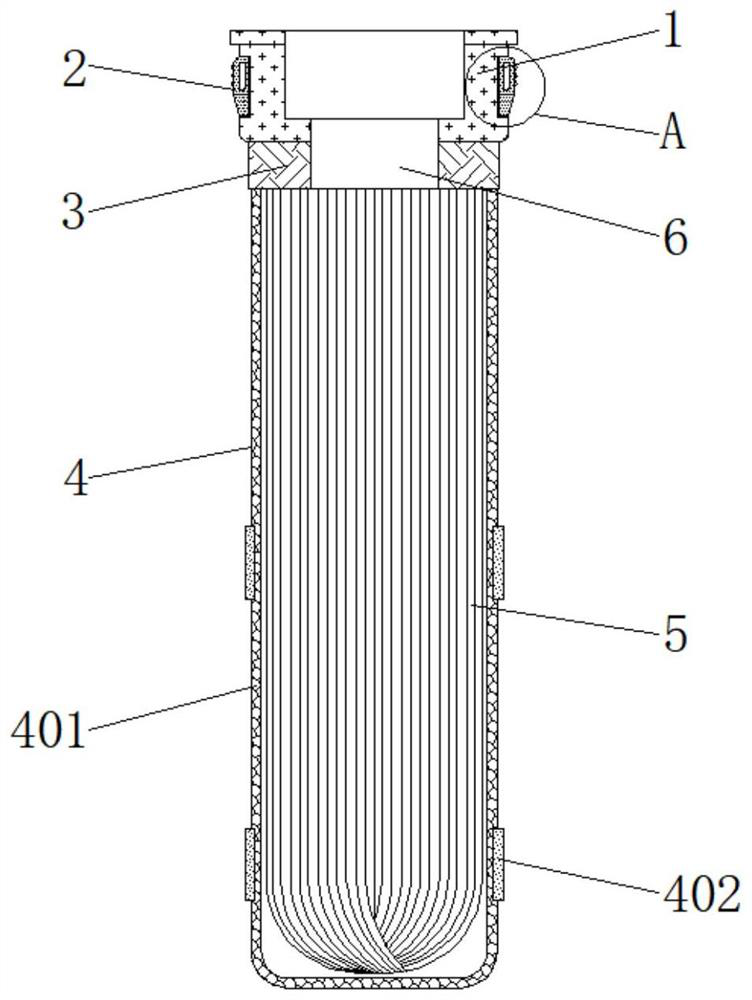

Hydrophilic hollow fiber ultrafiltration membrane

The invention discloses a hydrophilic hollow fiber ultrafiltration membrane which comprises a mounting connector, a connecting block, a hollow fiber ultrafiltration membrane body and a water inlet hole. A sealing structure is arranged on the outer side wall of the mounting connector, the bottom end of the mounting connector is fixedly connected with the connecting block, and the water inlet hole is formed in the mounting connector. A bundling structure is arranged at the bottom end of the connecting block, the hollow fiber ultrafiltration membrane body is arranged in the bundling structure, and a filtering structure is arranged in the hollow fiber ultrafiltration membrane body. Through the arrangement of a fixing groove, a sealing ring can be firmly fixed to the outer side wall of the mounting connector, when the outer wall of the sealing ring is extruded, deformation can be conducted by compressing a sealing air cavity, and the sealing ring can be more perfectly attached to an object. Meanwhile, through the arrangement of a protruding strip, triple protection is added, the sealing effect of the hydrophilic hollow fiber ultrafiltration membrane is improved, so that the hydrophilic hollow fiber ultrafiltration membrane has better sealing performance.

Owner:南京俊星金汇膜环保科技有限公司

3D printer used for food processing

ActiveCN109349674AImprove printing efficiencyImprove use valueFood shapingTorque sensorResistance wire

The invention discloses a 3D printer used for food processing. The 3D printer mainly comprises a sealing box body, a conveying platform, a raw material box, mechanical arms and printing spraying heads, conveying rails are arranged on the front and back sides of the bottom end of the sealing box body, and the conveying platform is in transmission connection with the conveying rails; the raw material box is fixedly connected to the left side of the sealing box body, a conveying frame is arranged on the upper side of the sealing box body, and the printing spraying heads are fixedly connected to the top ends of the mechanical arms; 1-6 mechanical arms can be arranged for installment of the printing spraying heads according to the technology requirements of food material varieties of food, independent areas of the raw material box are used for containing different raw materials, and the phenomenon of taint of odor can be effectively avoided; the printing spraying heads can be applied to printing materials such as dietary fiber and the like to avoid blocking of the spraying heads, multiple raw materials can be quickly printed within a short time, and each 3D printing spraying head is provided with a corresponding torque transducer, a corresponding pressure sensor and a corresponding heating resistance wire; data of the pressure value, the temperature value and the like correspondingto the 3D printer can be conveniently adjusted, types of 3D printing raw materials are expanded, the printing efficiency is improved, and the using value of the 3D printer is improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

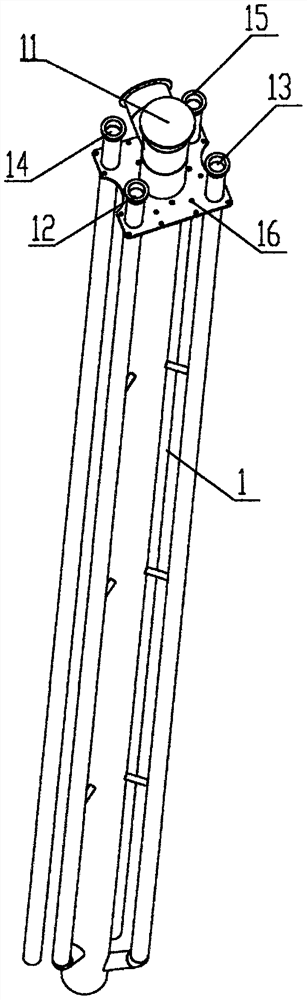

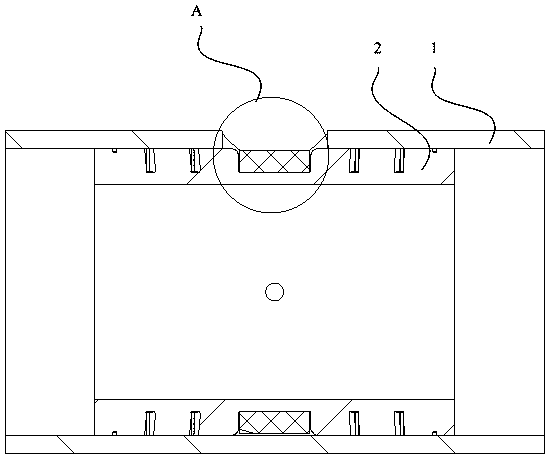

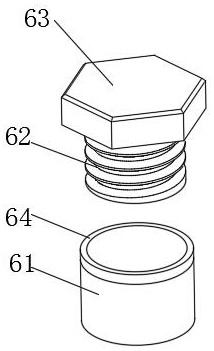

Drip irrigation pipe with anti-blocking function and processing method of drip irrigation pipe

PendingCN111053021AWith anti-blocking functionAvoid cloggingClimate change adaptationWatering devicesWater useDrip irrigation

The invention discloses a drip irrigation pipe with an anti-blocking function and a processing method of the drip irrigation pipe. The drip irrigation pipe includes a water supply pipe, a cylindricalwater dropper and an elastic sleeve, wherein the water supply pipe is used for conveying irrigation water, an annular groove is formed in the cylindrical water dropper, and water outlet holes which penetrate the cylindrical water dropper are formed in the annular groove; the cylindrical water dropper is sleeved by the elastic sleeve, the elastic sleeve is arranged in the annular groove, and the water outlet holes are covered by the elastic sleeve; and the cylindrical water dropper is arranged in the water supply pipe, a water outlet which is matched with the cylindrical water dropper is formedin the water supply pipe, and the water outlet is formed outside the annular groove. The anti-blocking performance and application reliability of the drip irrigation pipe are improved.

Owner:秦春明

Alcohol-based fuel gasification combustion stove

ActiveCN104848269BAvoid enteringAvoid exclusionDomestic stoves or rangesCombustion typesCombustionAlcohol

The invention provides an alcohol-based fuel vaporizing combustion furnace, which belongs to the technical field of a combustion furnace and aims at solving the problems that in the prior art, the blockage can easily occur, and the heated temperature difference is great, so that the furnace is damaged, the starting time is long, and the noise is great. The alcohol-based fuel vaporizing combustion furnace comprises a backflow heat-resistant filtering unit, a vaporizing unit, a fire intensity control unit, a heating starting unit, a fire spraying unit and a preheating unit, wherein the vaporizing unit is communicated with the backflow heat-resistant filtering unit through a material supply pipe; the fire intensity control unit is communicated with a vaporizing cavity branch pipe vaporizing unit; the heating starting unit and the fire spraying unit are communicated with the fire intensity control unit; the fire spraying unit comprises a fire spraying head and a fire spraying cavity; the fire spraying head comprises a fire distribution cap and a connecting rod; the fire distribution cap is in contact with a conical surface arranged at the upper end of the fire spraying cavity, so that the lower part of the cavity forms a gas spraying chamber, and the upper part of the cavity forms an annular spray nozzle; the lower end of the connecting rod is connected with the lower end of the fire spraying cavity through screw threads; a plurality of fire spraying grooves are uniformly distributed in the circumference of the lower end of the fire distribution cap; a gap is formed in the fire spraying cavity and the vaporizing cavity for forming an air distribution opening; an ignition needle is arranged in any position of the air distribution opening; the preheating unit is connected with the lower end of the fire spraying cavity of the fire spraying unit through screw threads.

Owner:闫云恒

A bridge with anti-blocking function

ActiveCN106884381BGuaranteed unobstructedEnsure traffic safetyBridge structural detailsForeign matterStructural engineering

The invention relates to the technical field of bridges, and particularly relates to a bridge with an anti-blocking function. The bridge comprises a bridge body, the bridge body comprises a bridge surface, bridge side girders are correspondingly arranged on the two sides of the bridge surface, a plurality of drainage holes are arranged on the bridge side girder, a solar panel is arranged on the outer side surface of the bridge side girder, a telescopic cylinder is arranged on one side of the upper part of the drainage hole on the inner side surface of the bridge side girder, a waterproof sealing box is installed on the telescopic cylinder, a cylinder shaft hole is arranged on the left side surface of the waterproof sealing box, a seal ring is embedded in the cylinder shaft hole, a pushing plate is arranged at the end tip of a cylinder shaft, extending outside the cylinder shaft hole, of the telescopic cylinder, a grid mesh is arranged on the drainage hole to form first-level blocking prevention, the cylinder shaft on the cylinder cleans foreign matters on the drainage hole to form second-level blocking prevention; the bridge has the multiple anti-blocking function, the smoothness of the drainage hole is guaranteed, water is guaranteed not to be accumulated on the bridge surface, the safe passing of a vehicle is finally guaranteed, and the occurrence of potential safety hazards is completely eradicated.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

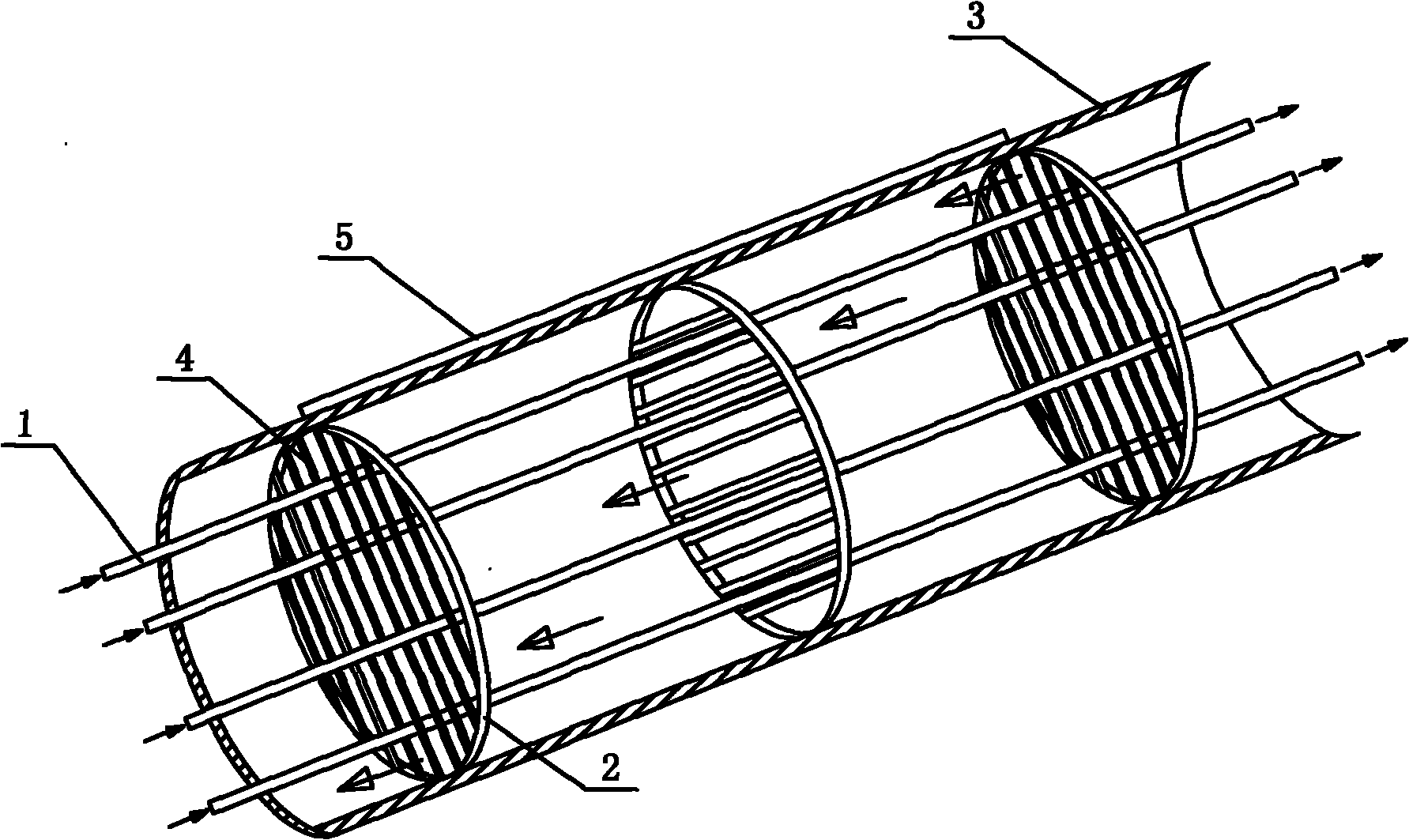

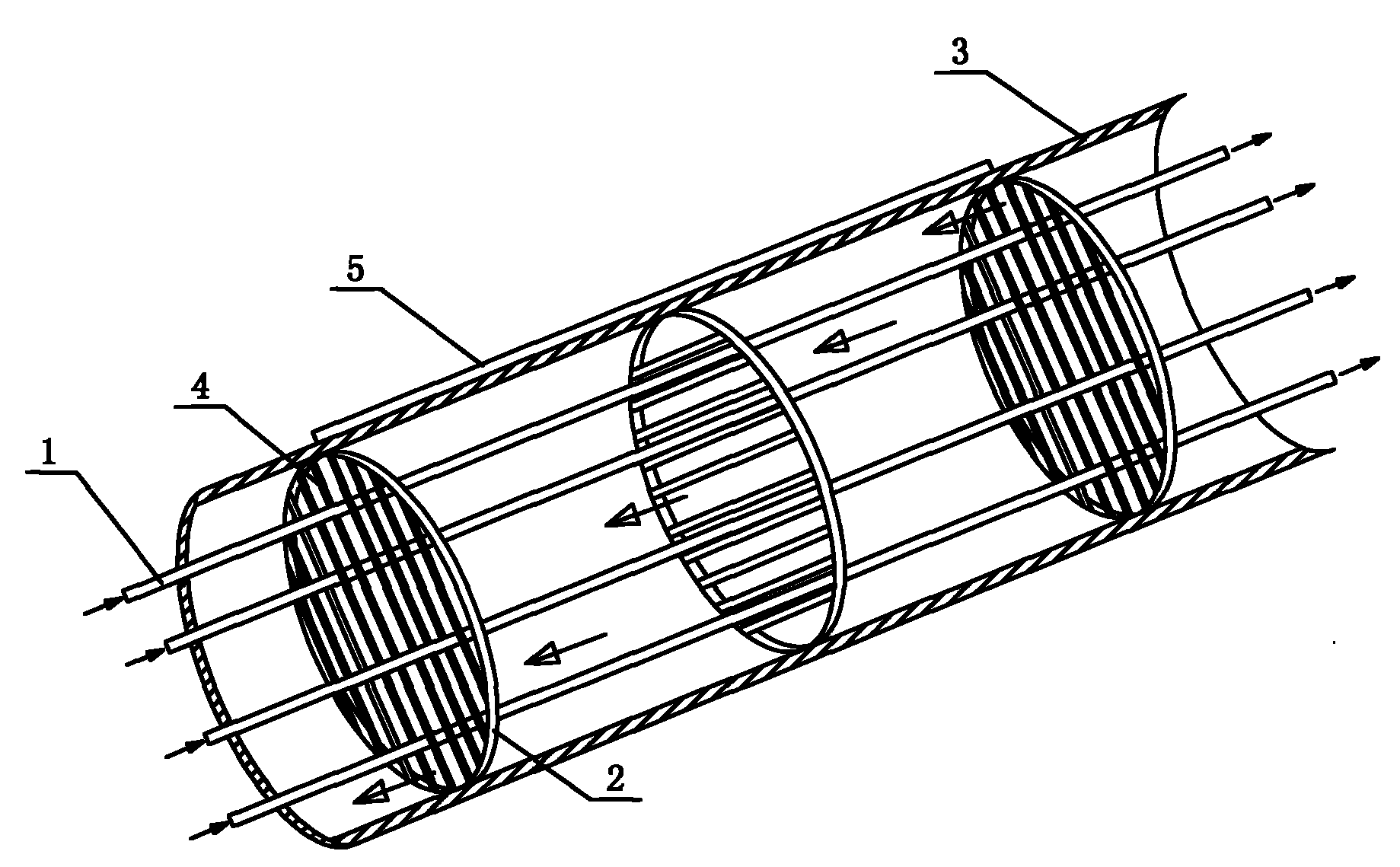

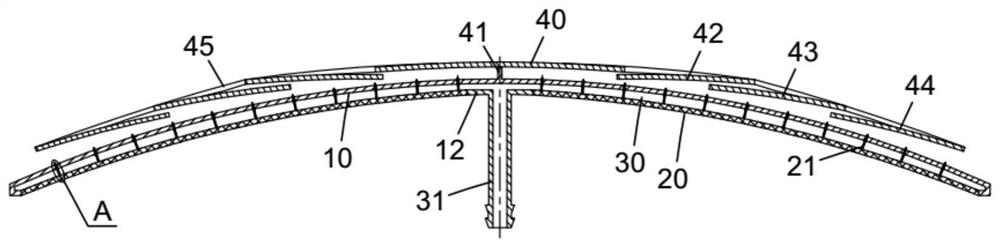

Heat pump large-diameter heat exchange device and system thereof for sewage or earth surface water source

InactiveCN101915511BPass smoothlyWith anti-blocking functionHeat pumpsStationary tubular conduit assembliesWater sourceEngineering

The invention relates to a heat pump large-diameter heat exchange device and a system thereof for sewage or earth surface water source, in particular to a heat exchange device and a system thereof for picking up heat or refrigeration in sewage or earth surface water by a heat pump technology. The invention aims at solving the key problems of suspended matter blockage, complex process flow, large area occupation, and the like of the traditional technology for preventing blockage. The device provided by the invention is composed of two monomer heat exchange devices in series, wherein the monomer heat exchange device comprises a large-diameter tube, a tube plate, a shell, an inside baffle plate, an outside baffle plate, a sewage or earth surface water inlet, a sewage or earth surface water outlet, a cleaning water inlet, a cleaning water outlet, a sealing plate, and the like. The system comprises the heat exchange device, a heat pump set, a water pump, connecting pipelines, and the like. Sewage or earth surface water flows smoothly in the large-diameter tube, and cleaning water is in a counter-current flow with the sewage outside the tube. The heat pump set then picks up heat from the cleaning water. The invention is suitable for indirect systems of heat pumps for sewage or earth surface water source, and the front end does not need to be provided with a filter screen or a blockage prevention device. The invention realizes blockless continuous heat exchange and heat picking, and has the advantages of sufficient corrosion allowance, little area occupation, high heat exchange efficiency, and the like.

Owner:青岛科创蓝新能源股份有限公司

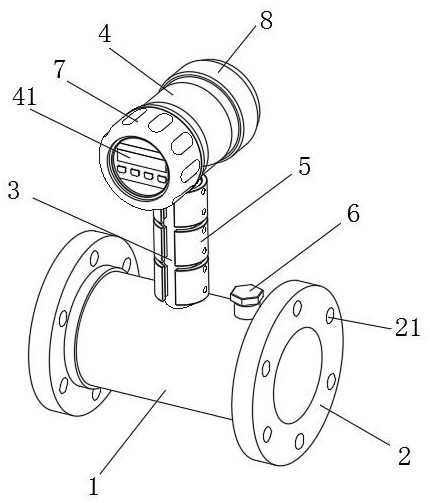

A differential pressure flowmeter in a waste water pipeline

ActiveCN110967073BWill not be bumped and damagedImprove protectionNon-rotating vibration suppressionVolume meteringWastewaterGuide tube

The invention relates to the field of differential pressure flowmeters, and discloses a differential pressure flowmeter in a waste water pipeline, which includes a pipe body, the outer surface of the upper end of the pipe body is provided with a pressure guiding tube, and the lower end of the pressure guiding tube Extending to the inner side of the pipe body, and the pressure guiding tube is fixedly connected with the tube body, the outer surface of the pressure guiding tube is provided with a buffer structure, the upper end of the pressure guiding tube is connected to the main body of the flowmeter, and the flowmeter The front end of the main body is movably equipped with a protective structure, the rear end of the flowmeter main body is provided with an anti-collision structure, and the outer surface of the upper end of the pipe body is provided with a dredging structure on the side close to the pressure guiding tube. The differential pressure flowmeter in the waste water pipeline has the advantages that the pressure guide tube is not easy to be damaged, the instrument panel is not easy to be scratched, plays a good protective role during the transportation process, and is easy to clean the dirt accumulated in the pipe body.

Owner:谈格

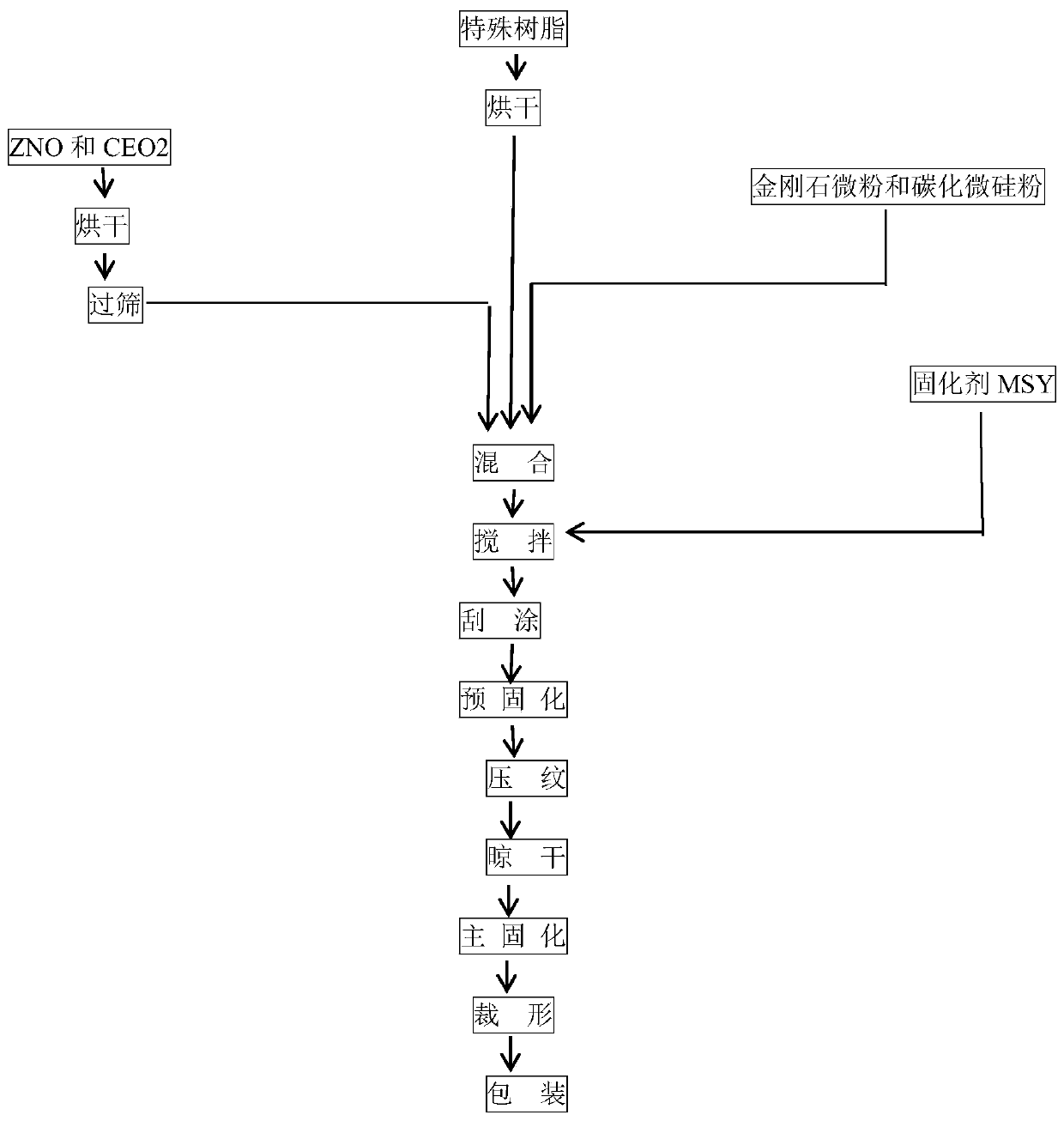

Diamond gasket and production method thereof

InactiveCN110922096ASimple componentsWith anti-blocking functionLapping toolsCarbide siliconCerium(IV) oxide

The invention discloses a diamond gasket and a production method thereof. The diamond gasket comprises, by weight, 1-20 parts of engineering plastic, 1-20 parts of thermosetting resin, 1-20 parts of aplasticizer, 5-35 parts of diamond, 10-40 parts of silicon carbide, 10-40 parts of zinc oxide, 5-35 parts of cerium dioxide and 0.5-10 parts of a curing agent. The purpose of the invention is to overcome the defects in the prior art. The provided diamond gasket has the advantages of simple component, reasonable combination, increase of the forming rate of the product, reduction of the use amountof a solvent, reduction of the use amount of diamond, so that the production cost is greatly reduced, and the bonding and grinding capabilities of the product are improved.

Owner:SHAOGUAN DATANG GRINDING MATERIAL CO LTD

A kind of sintered permeable brick and its preparation method

ActiveCN106087631BGood water permeabilityPermeability hasSingle unit pavingsPaving detailsBrickPolymer science

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com