Diamond gasket and production method thereof

A diamond and gasket technology, which is applied in the field of preparing the above-mentioned diamond gaskets and diamond gaskets, can solve the problems of large solvent usage, large diamond consumption, and high raw material costs, and achieve reduced production processes, good grinding performance, and softness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

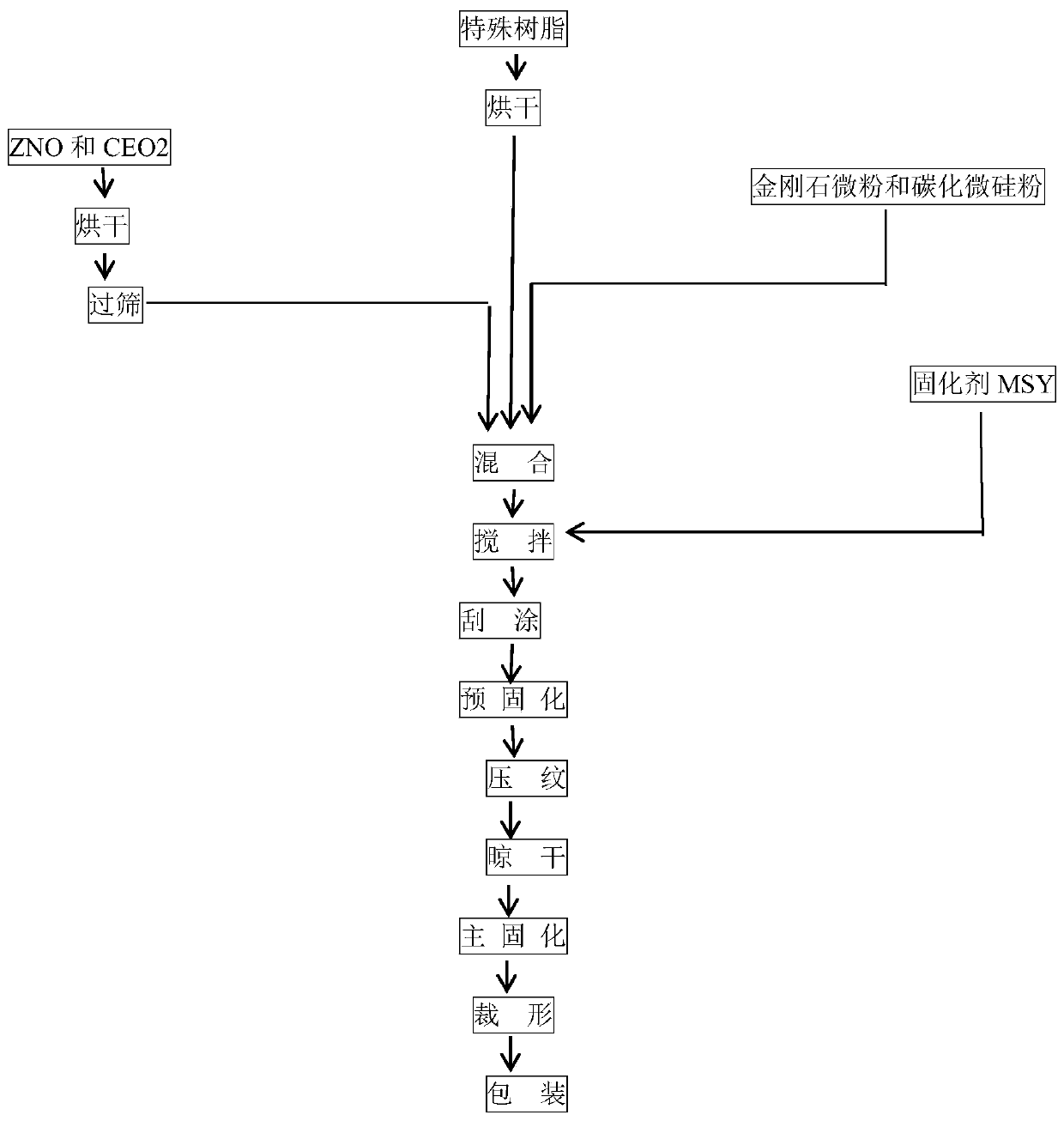

Method used

Image

Examples

Embodiment 1

[0039] A kind of diamond gasket comprises the following components by weight:

[0040] 10 parts of POX, 10 parts of PRE, 10 parts of dioctyl phthalate DOP, 20 parts of diamond, 25 parts of silicon carbide, 20 parts of zinc oxide, 20 parts of cerium oxide, 5 parts of MSY.

Embodiment 2

[0042] A kind of diamond gasket comprises the following components by weight:

[0043] 1 part of polyethylene, 1 part of melamine formaldehyde resin, 1 part of epoxy octyl stearate, 5 parts of diamond, 10 parts of silicon carbide, 10 parts of zinc oxide, 5 parts of cerium oxide, 0.5 part of m-phenylenediamine.

Embodiment 3

[0045] A kind of diamond gasket comprises the following components by weight:

[0046] 20 parts of mixture of polyethylene and polypropylene, 20 parts of mixture of melamine formaldehyde resin and furan resin, 20 parts of dibutyl phthalate DBP, 35 parts of diamond, 40 parts of silicon carbide, 40 parts of zinc oxide, 35 parts of cerium oxide Parts, 10 parts of a mixture of 2-methylimidazole and dodecenyl succinic anhydride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com